Introduction

Automated conveyor and sortation systems are revolutionizing the logistics landscape. They drive efficiency and accuracy in an industry where speed and precision are crucial. Companies like Crossfire Logistics are adopting these innovative technologies, which offer numerous benefits, including reduced labor costs and improved order fulfillment capabilities.

However, as automation evolves rapidly, a critical question emerges: how can businesses effectively integrate these systems? The goal is not just to keep pace with market demands but also to surpass competitors. Addressing this challenge requires strategic planning and a clear understanding of the technology's potential.

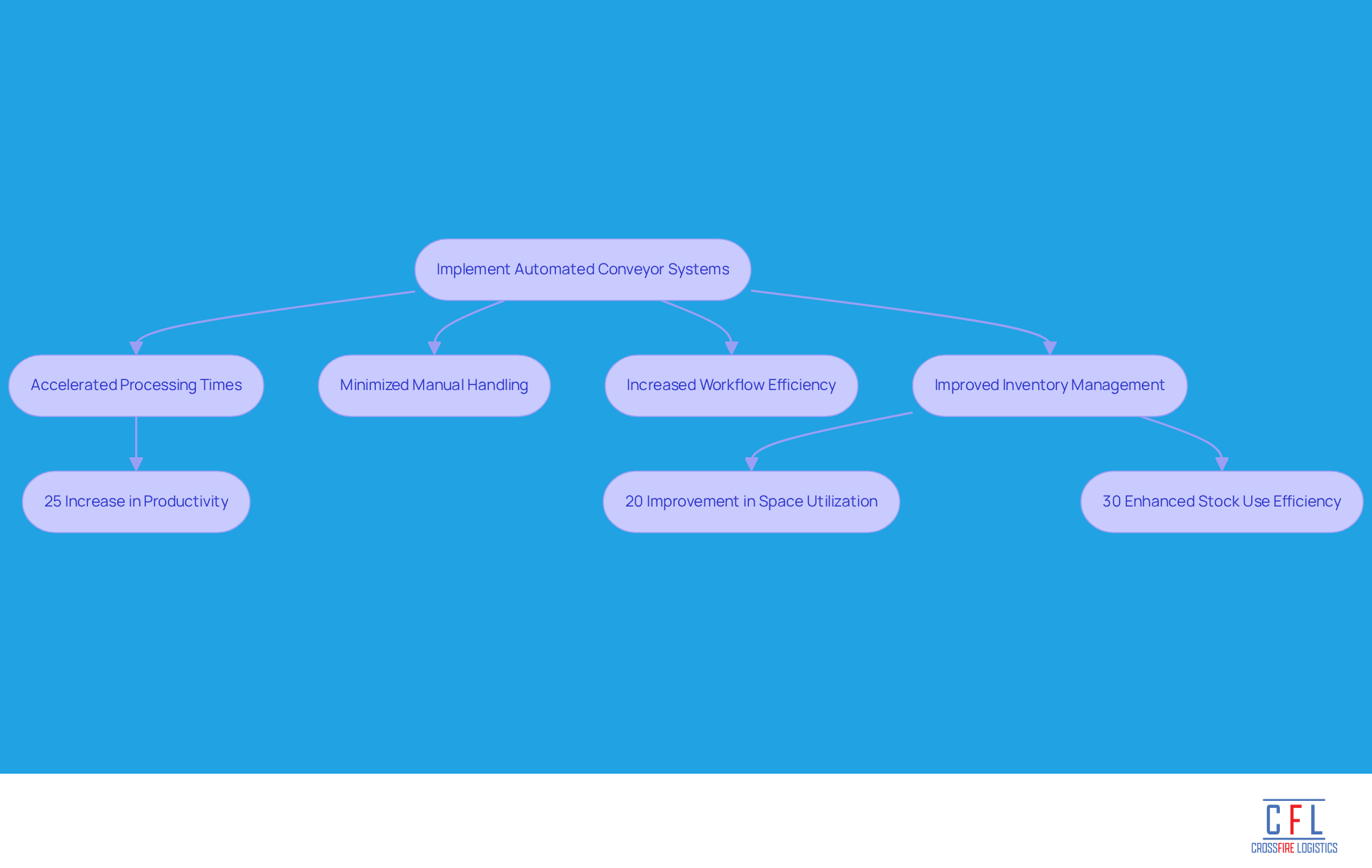

Crossfire Logistics: Streamlining Operations with Automated Conveyor Systems

Crossfire Logistics utilizes automated conveyor and sortation systems to enhance product movement within its warehouses. This setup significantly accelerates processing times, minimizes manual handling, and boosts overall workflow efficiency. By implementing automated conveyor and sortation systems, Crossfire effectively manages inventory, ensuring swift transitions from receiving to storage and ultimately to shipping. This streamlined approach not only increases operational speed but also enhances accuracy in order fulfillment, which is crucial for maintaining high levels of customer satisfaction.

The impact of these systems is evident in case studies that demonstrate their effectiveness. Companies adopting automated conveyor and sortation systems report a 25% increase in productivity and a 20% improvement in space utilization. Furthermore, warehouse mechanization can enhance stock use efficiency by 30%. Supply chain management specialists emphasize that mechanization is essential for sustaining competitiveness in an increasingly complex supply network. As industry leaders note, "Automation significantly boosts operational efficiency and productivity by optimizing storage and retrieval processes." Additionally, Saif Ali states, "When supply chains grow more intricate, warehouse technology becomes crucial in sustaining competitiveness and facilitating scalability for future expansion."

Integrating automated conveyor and sortation systems enables Crossfire Logistics to not only meet but exceed client expectations, positioning the company as a leader in efficient logistics solutions. However, it is important to acknowledge the potential challenges of integrating these automation technologies with outdated frameworks, which can impact the overall efficiency of the implementation.

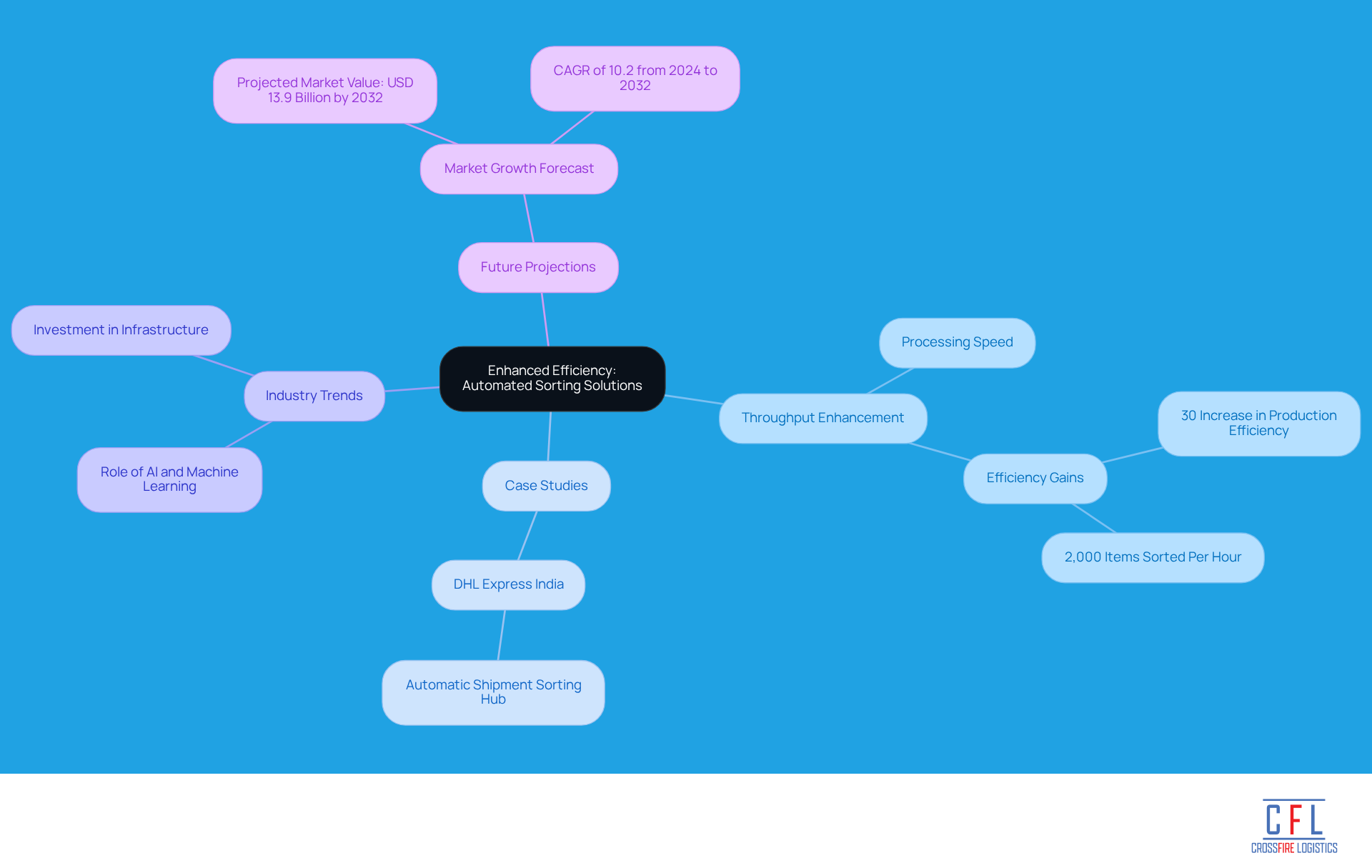

Enhanced Efficiency: Boosting Throughput with Automated Sorting Solutions

Automated sorting solutions significantly enhance throughput by utilizing automated conveyor and sortation systems to swiftly and accurately categorize items for distribution. These automated conveyor and sortation systems are capable of processing thousands of items per hour, ensuring that products are sorted and dispatched without delay. For instance, DHL Express India's automated conveyor and sortation systems sort 2,000 items each hour, resulting in a 30% increase in production efficiency directly linked to the implementation of automatic sorting technologies.

By adopting these technologies, Crossfire Logistics accelerates the order fulfillment process and minimizes bottlenecks. This fosters a more responsive supply chain that adapts seamlessly to fluctuating demand. Industry leaders emphasize that automated conveyor and sortation systems are essential for managing the growing volume of packages and ensuring timely deliveries.

As the supply chain landscape evolves, the latest trends in sorting technology, particularly automated conveyor and sortation systems, along with advancements in AI and machine learning, are set to further enhance operations. These innovations will improve overall throughput and order fulfillment speed. The mechanized sorting market is projected to reach USD 13.9 billion by 2032, underscoring the critical role of mechanization in logistics.

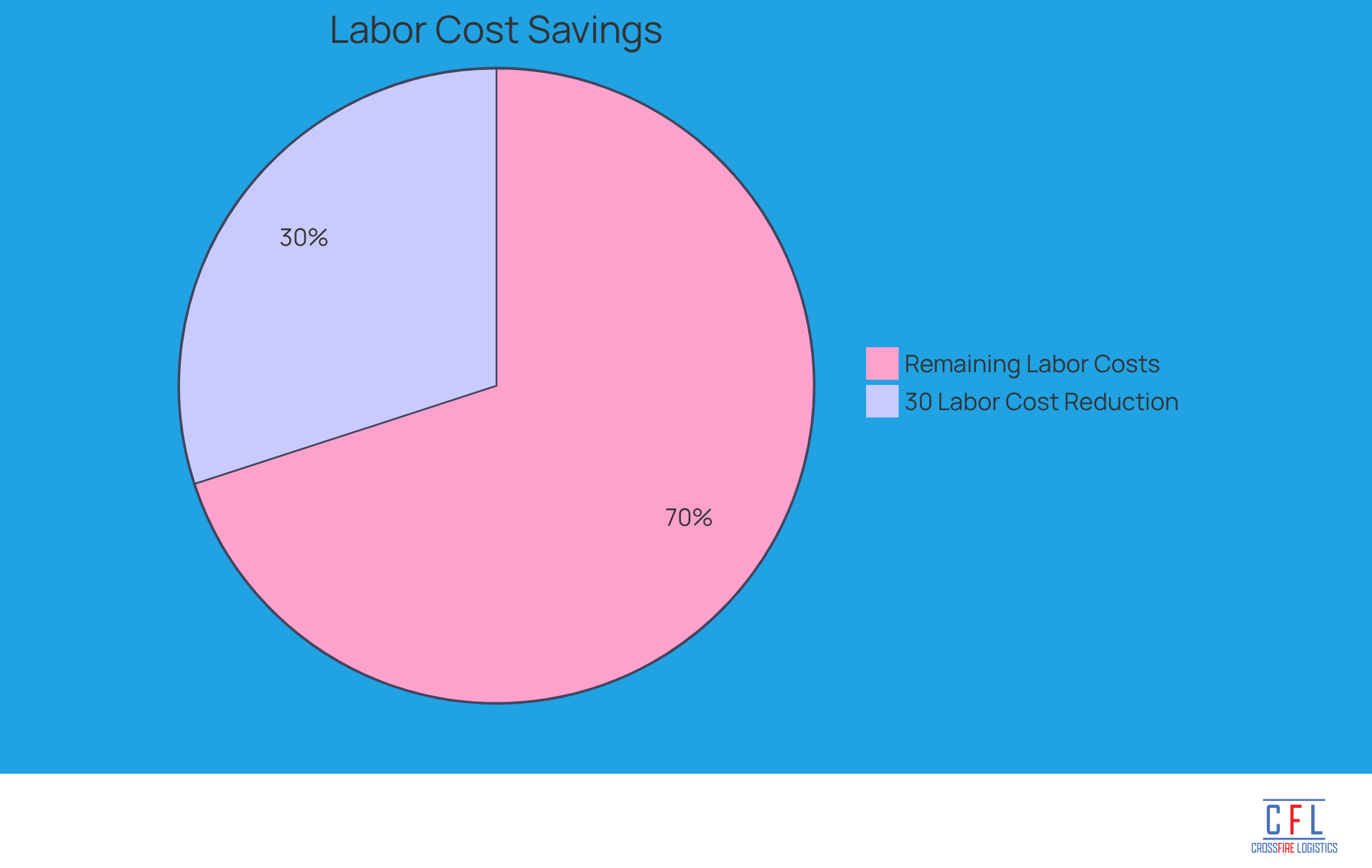

Cost Reduction: Lowering Labor Expenses through Automation

A significant advantage of automated conveyor and sortation systems is their ability to reduce labor costs. By utilizing automated conveyor and sortation systems to automate repetitive tasks, Crossfire Logistics can decrease the number of employees needed for sorting and transporting goods. This reduction not only lowers payroll expenses but also enables the workforce to concentrate on more strategic tasks, thereby enhancing overall productivity.

Studies show that companies can achieve labor cost reductions of up to 30% through effective automation.

Improved Accuracy: Minimizing Errors with Automated Sorting Technologies

Automated conveyor and sortation systems are essential for minimizing human error in logistics operations. These systems leverage advanced algorithms and sensors to ensure precise and efficient sorting of items. For Crossfire Logistics, this means a notable decrease in mistakes during order fulfillment, which enhances customer satisfaction and lowers return rates.

The increased accuracy not only streamlines operations but also builds trust among clients who rely on timely and accurate deliveries. Robotic systems can achieve picking accuracy rates of up to 99.99%, and they can reduce picking errors by as much as 70%. This represents a significant improvement over traditional manual processes.

Moreover, companies that implement automated conveyor and sortation systems report a 25% boost in productivity, underscoring the operational efficiency gained through these technologies. A case study reveals that 62% of warehouses identified human error in manual processes as the leading cause of inventory fulfillment issues, emphasizing the need for mechanization to improve accuracy.

As the logistics landscape evolves, the integration of automated conveyor and sortation systems is becoming vital for maintaining a competitive edge and meeting the growing demands for rapid and precise order fulfillment. With the warehouse technology market projected to exceed $50 billion by 2030, companies should evaluate their current sorting methods and explore mechanized solutions to enhance accuracy and efficiency.

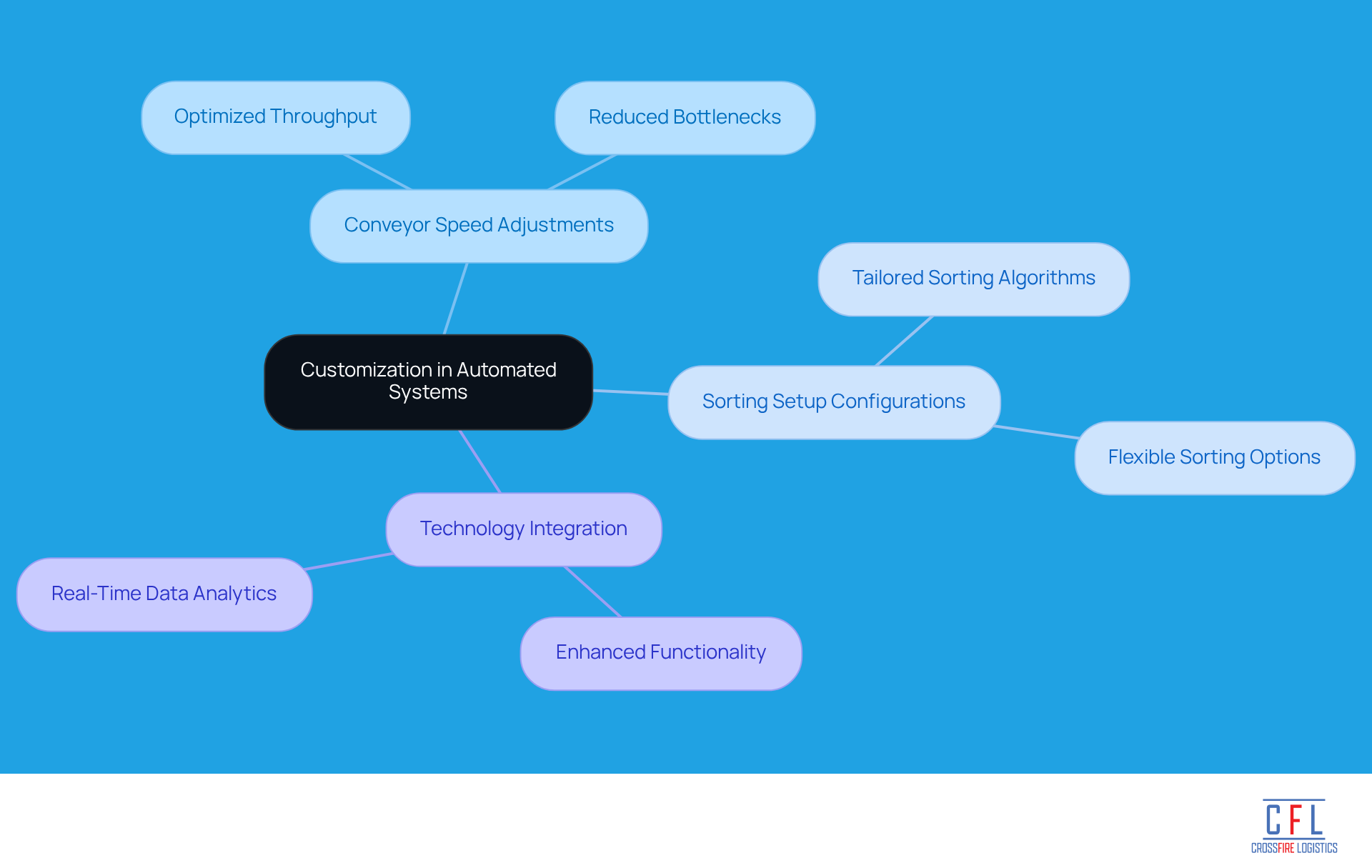

Customization: Tailoring Automated Systems to Fit Unique Logistics Requirements

Crossfire Logistics recognizes that a one-size-fits-all approach to automation is inadequate. The company specializes in personalizing automated conveyor and sortation systems to address the unique logistical challenges faced by its clients. This tailored approach ensures that the systems implemented are not only efficient but also aligned with the specific operational objectives of each business.

Customization can take various forms, including:

- Adjustments to conveyor speeds

- The configuration of sorting setups

- The integration of additional technologies to enhance functionality

By focusing on these personalized solutions, Crossfire Logistics effectively meets the diverse needs of its clientele through automated conveyor and sortation systems.

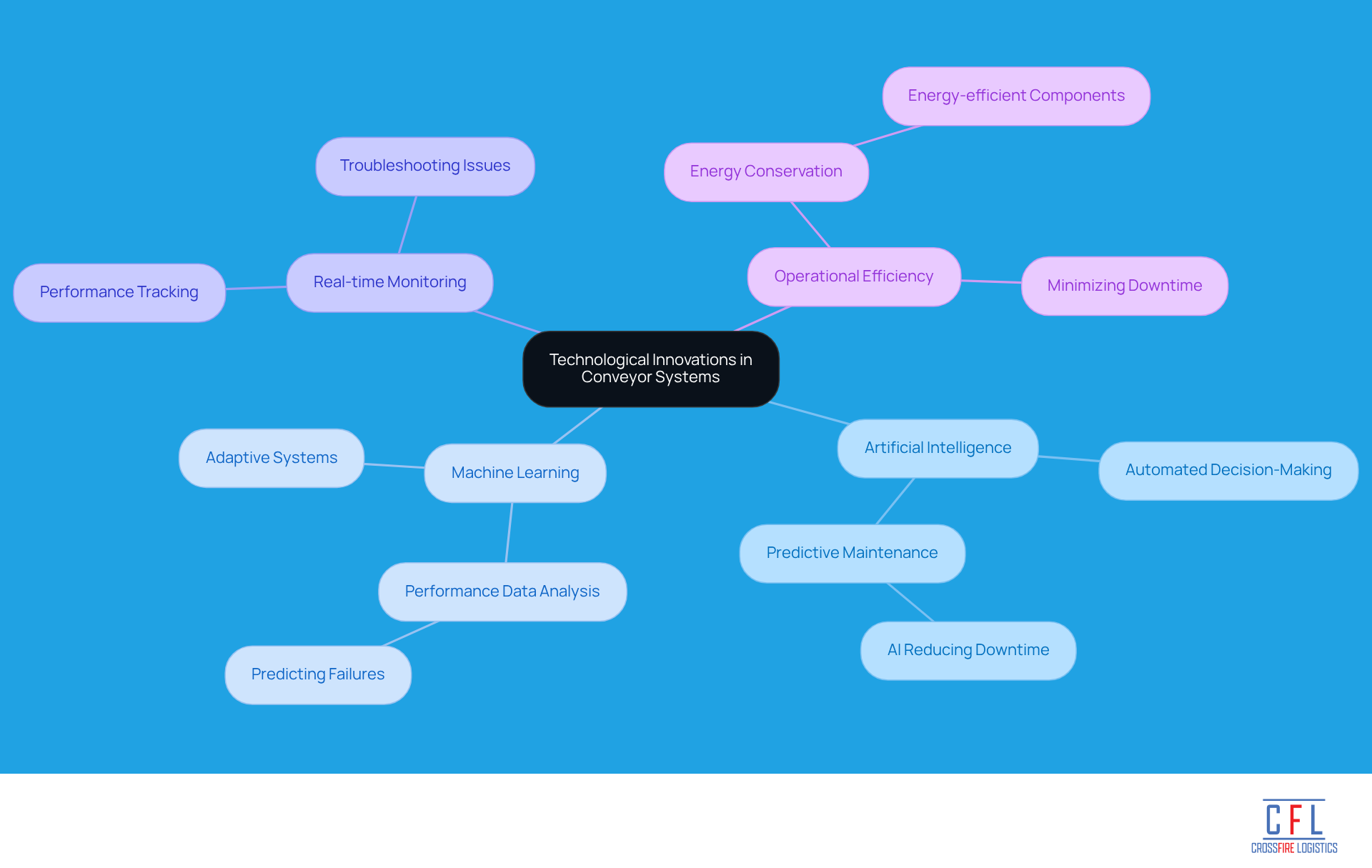

Technological Innovations: Advancements in Automated Conveyor Systems

Recent advancements in conveyor technology highlight the integration of artificial intelligence and machine learning. These innovations significantly enhance the ability to adapt to changing operational demands.

Real-time monitoring and adjustments optimize performance and minimize downtime. Crossfire Logistics leads the way in adopting these technologies, ensuring operations are not only efficient but also resilient against evolving industry standards.

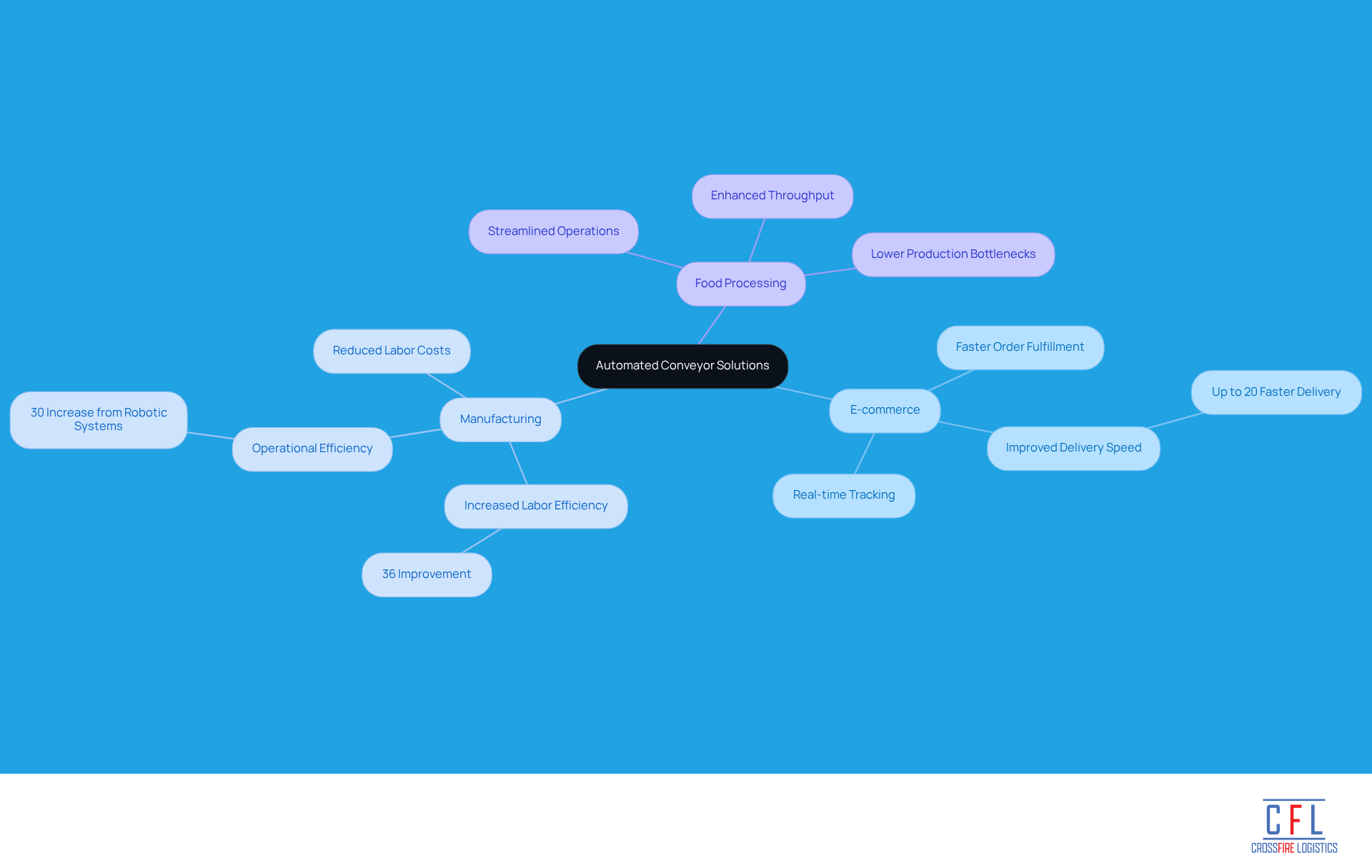

Industry Applications: Sectors Benefiting from Automated Conveyor Solutions

Automated conveyor and sortation systems are revolutionizing operations across various industries, including e-commerce, manufacturing, and food processing. In e-commerce, companies are leveraging these systems to achieve faster order fulfillment, which is crucial as consumer expectations for rapid delivery continue to rise. The integration of self-operating technologies has enabled e-commerce businesses to significantly reduce order handling times, with reports indicating improvements in delivery speed by up to 20%. This efficiency is essential in a market where consumers demand real-time tracking and one-to-two-day delivery.

Manufacturers are reaping the benefits of streamlined production lines that enhance throughput and lower labor costs. Automation in manufacturing has resulted in a 36% increase in labor efficiency, allowing companies to reallocate their workforce to more value-added tasks. A notable case study illustrates how a manufacturing firm implemented robotic conveyor systems, leading to a 30% increase in operational efficiency and a substantial reduction in production bottlenecks.

Experts in supply chain management emphasize the importance of mechanization in meeting the evolving demands of the market. As one industry leader remarked, "If you can't get people to take certain jobs that need to be done, then the next best thing is accomplishing the tasks without a human doing the work." This perspective underscores the growing trend of technology adoption, with 52% of warehouse managers anticipating increased investment in robotics and mechanized solutions in the coming years.

Looking ahead to 2025, e-commerce delivery trends are shifting, propelled by advancements in AI and IoT technologies. These innovations facilitate more agile operations, enabling businesses to swiftly adapt to changes in demand. As the industry embraces automation, the focus remains on enhancing efficiency, reducing costs, and improving customer satisfaction, which makes automated conveyor and sortation systems an integral component of modern supply chain strategies.

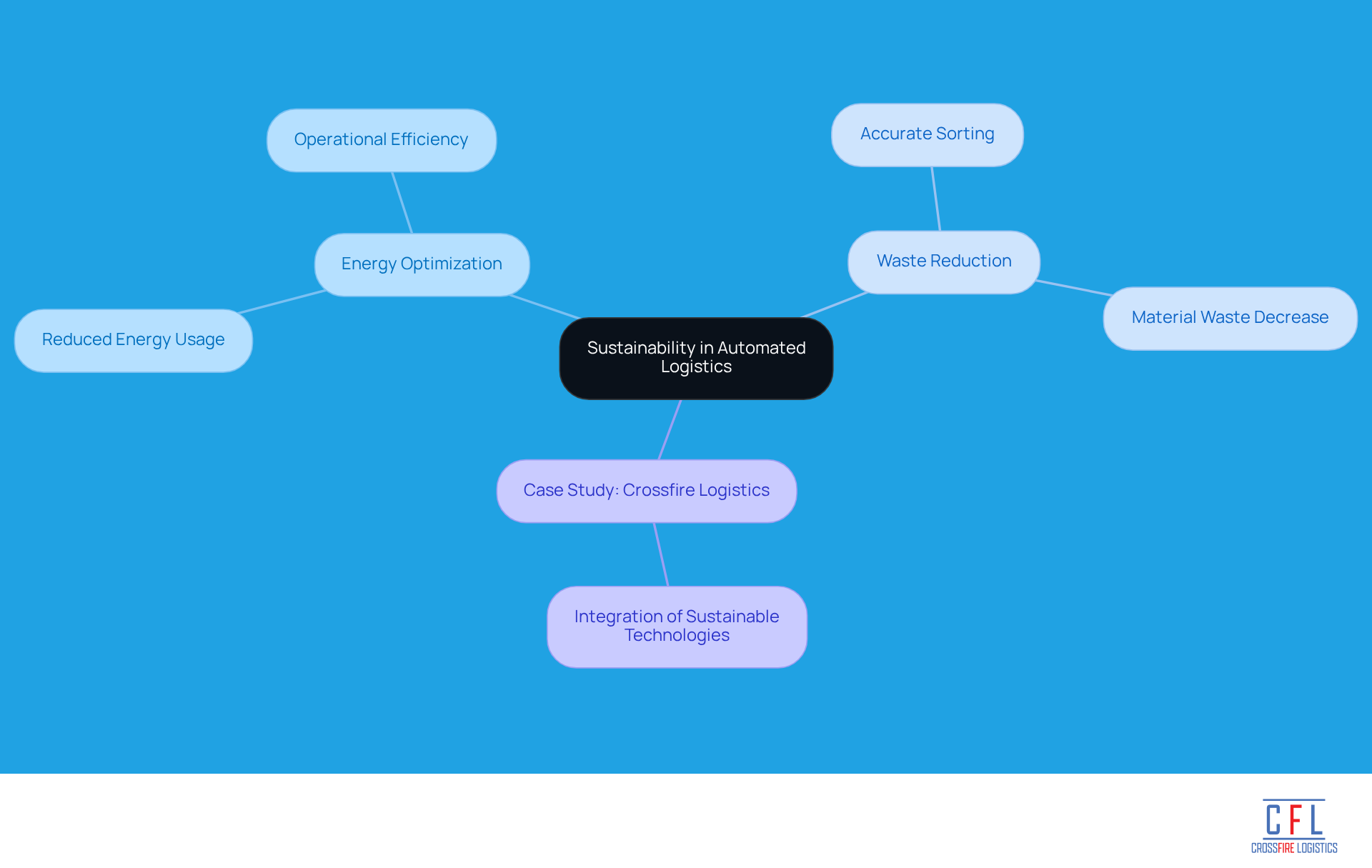

Sustainability: Eco-Friendly Practices in Automated Logistics Solutions

Automated conveyor and sortation systems play a crucial role in promoting sustainability by optimizing energy consumption and minimizing waste.

For example, automated conveyor and sortation systems can be designed to reduce energy usage during operation. Additionally, the implementation of automated conveyor and sortation systems can significantly decrease material waste by ensuring accurate sorting.

Crossfire Logistics exemplifies a commitment to eco-friendly practices, integrating sustainable technologies into its operations. This approach not only enhances efficiency but also reinforces environmental responsibility.

Future Trends: The Evolution of Automated Conveyor and Sortation Systems

Significant advancements are expected in the future of automated conveyor and sortation systems, primarily driven by the growing integration of robotics and AI. These technologies are anticipated to enhance efficiency and adaptability in logistics operations.

For instance, facilities utilizing AI for intralogistics have reported a 30 to 40 percent reduction in material travel time compared to traditional methods. This statistic underscores the tangible benefits of automation.

As e-commerce continues its upward trajectory, with sales increasing by 16.6% in 2022, the demand for efficient automated conveyor and sortation systems is increasing. Crossfire Logistics is closely monitoring these trends, ensuring it stays at the forefront of the supply chain sector by adopting the latest innovations that promote operational excellence.

Industry reports predict that the adoption of robotics and automation in supply chains will escalate from 41% to 83% among supply chain leaders over the next five years. This projection highlights the crucial role these technologies will play in shaping the future of automation in transportation.

Overall Impact: Transforming Logistics Operations with Automation

Automated conveyor and sortation systems significantly impact supply chain operations, enhancing efficiency, cost management, and precision. For Crossfire Logistics, the use of automated conveyor and sortation systems streamlines processes, boosting operational productivity by up to 60% and improving picking accuracy by as much as 99%. This transformation not only lowers operational costs but also enhances customer satisfaction, as timely and accurate deliveries become standard. As logistics firms increasingly adopt automated conveyor and sortation systems, they can expect notable improvements in service quality and responsiveness, which are vital for maintaining a competitive edge in a rapidly evolving market.

Case studies exemplify this shift. Fosfa Logistics, for example, has implemented automated conveyor and sortation systems in a fully mechanized warehouse that operates almost autonomously, achieving same-day order fulfillment and significantly increasing picking speed. Similarly, Walmart plans to reroute 55% of its fulfillment volume through automated conveyor and sortation systems in entirely automated facilities by 2026, underscoring the industry's commitment to mechanization for enhanced efficiency.

Industry leaders emphasize the necessity of embracing mechanization. Kevin Nolan, founder of Nolan Transportation Group, notes that while automation alone won't guarantee business success, it greatly enhances human efficiency in transportation operations. This perspective resonates throughout the sector, as companies acknowledge that the integration of automated conveyor and sortation systems is crucial for optimizing logistics processes and elevating customer satisfaction.

Conclusion

The implementation of automated conveyor and sortation systems is revolutionizing logistics operations, driving efficiency, accuracy, and cost-effectiveness. Companies like Crossfire Logistics are enhancing their operational capabilities and setting new standards for customer satisfaction and service quality in the industry.

Key benefits include:

- Increased productivity, with reports indicating a boost of up to 25%

- Significant reductions in labor costs, achieving savings of up to 30%

- Minimization of errors, enhancing fulfillment accuracy to levels as high as 99.99%

- Customization of systems, allowing businesses to tailor solutions that meet their unique operational needs

As the logistics landscape evolves, embracing automation is essential for maintaining a competitive edge. Companies should evaluate their current practices and consider integrating automated conveyor and sortation systems to reap the benefits of improved efficiency, reduced costs, and heightened accuracy. The future of logistics lies in automation; investing in these technologies today will pave the way for sustainable growth and success in the years to come.

Frequently Asked Questions

What are automated conveyor and sortation systems used for at Crossfire Logistics?

Automated conveyor and sortation systems are used to enhance product movement within Crossfire Logistics' warehouses, significantly accelerating processing times, minimizing manual handling, and boosting overall workflow efficiency.

How do automated systems impact inventory management at Crossfire Logistics?

These systems effectively manage inventory by ensuring swift transitions from receiving to storage and ultimately to shipping, which increases operational speed and enhances accuracy in order fulfillment.

What productivity and efficiency improvements have companies experienced by adopting these automated systems?

Companies adopting automated conveyor and sortation systems report a 25% increase in productivity, a 20% improvement in space utilization, and a 30% enhancement in stock use efficiency.

Why is mechanization important in supply chain management?

Mechanization is essential for sustaining competitiveness in an increasingly complex supply network, as it significantly boosts operational efficiency and productivity by optimizing storage and retrieval processes.

What challenges might arise from integrating automated systems?

Potential challenges include difficulties in integrating these automation technologies with outdated frameworks, which can impact the overall efficiency of the implementation.

How do automated sorting solutions improve throughput?

Automated sorting solutions enhance throughput by swiftly and accurately categorizing items for distribution, processing thousands of items per hour, and minimizing bottlenecks in the order fulfillment process.

What specific example illustrates the efficiency of automated sorting systems?

DHL Express India's automated conveyor and sortation systems sort 2,000 items each hour, resulting in a 30% increase in production efficiency linked to the implementation of automatic sorting technologies.

What future trends are expected in sorting technology?

Advancements in AI and machine learning, along with automated conveyor and sortation systems, are expected to further enhance operations, improving overall throughput and order fulfillment speed.

How does automation affect labor costs at Crossfire Logistics?

Automation reduces labor costs by decreasing the number of employees needed for sorting and transporting goods, allowing the workforce to focus on more strategic tasks, which enhances overall productivity.

What is the projected market size for the mechanized sorting market by 2032?

The mechanized sorting market is projected to reach USD 13.9 billion by 2032, highlighting the critical role of mechanization in logistics.