Introduction

In an era where efficiency and accuracy are paramount, automated stock control has emerged as a transformative solution for logistics operations. This technology streamlines inventory management and provides significant benefits, such as:

- Enhanced visibility

- Reduced errors

- Improved decision-making capabilities

However, as companies increasingly adopt these systems, they encounter challenges related to:

- Integration

- Scalability

Understanding the true advantages of automated stock control is essential. Organizations must navigate the complexities of implementation to achieve logistics success.

Crossfire Logistics: Enhanced Inventory Management through Automation

Crossfire Logistics employs automated stock control to enhance operational efficiency and ensure accurate stock levels, significantly reducing manual errors. This integration of advanced technology into their supply chain framework improves visibility and control over stock, which is vital for efficiently meeting customer demands.

This strategic approach minimizes stock discrepancies and optimizes warehouse space usage, leading to better resource oversight. The implementation of automation not only streamlines operations but also boosts overall productivity, enabling employees to concentrate on higher-value tasks such as quality control and data analysis.

Industry specialists emphasize that organizations adopting automated stock control can expect improved precision in stock monitoring, a critical factor for maintaining a competitive edge in the transportation sector. Furthermore, automated stock management leads to substantial cost savings by decreasing excess storage fees and enhancing spend management, ultimately driving profitability and operational resilience.

Real-Time Data Acquisition: Improving Decision-Making in Stock Control

Real-time data acquisition empowers logistics companies to utilize automated stock control for continuous monitoring of stock levels. This capability enables automated stock control, facilitating timely replenishment and significantly reducing the risk of stockouts. By utilizing sophisticated data analysis, companies can achieve automated stock control to forecast demand variations precisely and modify stock levels proactively.

This strategic approach boosts operational efficiency and enhances resource allocation and planning with automated stock control. For instance, companies that leverage real-time data have reported up to a 30% improvement in inventory accuracy, as seen with Amazon's effective resource allocation. Furthermore, organizations implementing real-time tracking and analytics have experienced a 15% increase in sales due to improved product availability. This underscores the importance of data-driven decision-making in today’s competitive landscape.

Additionally, real-time tracking can save businesses money by reducing missed deliveries, highlighting the financial benefits of these systems. However, it is essential to acknowledge that implementing real-time data systems may present challenges, such as technology compatibility and scalability issues.

As supply chain operations increasingly depend on real-time insights, the ability to react quickly to market changes becomes a key differentiator in achieving success. According to a supply chain analyst, "Data analytics is transforming decision-making processes, allowing companies to make informed choices that enhance efficiency and customer satisfaction.

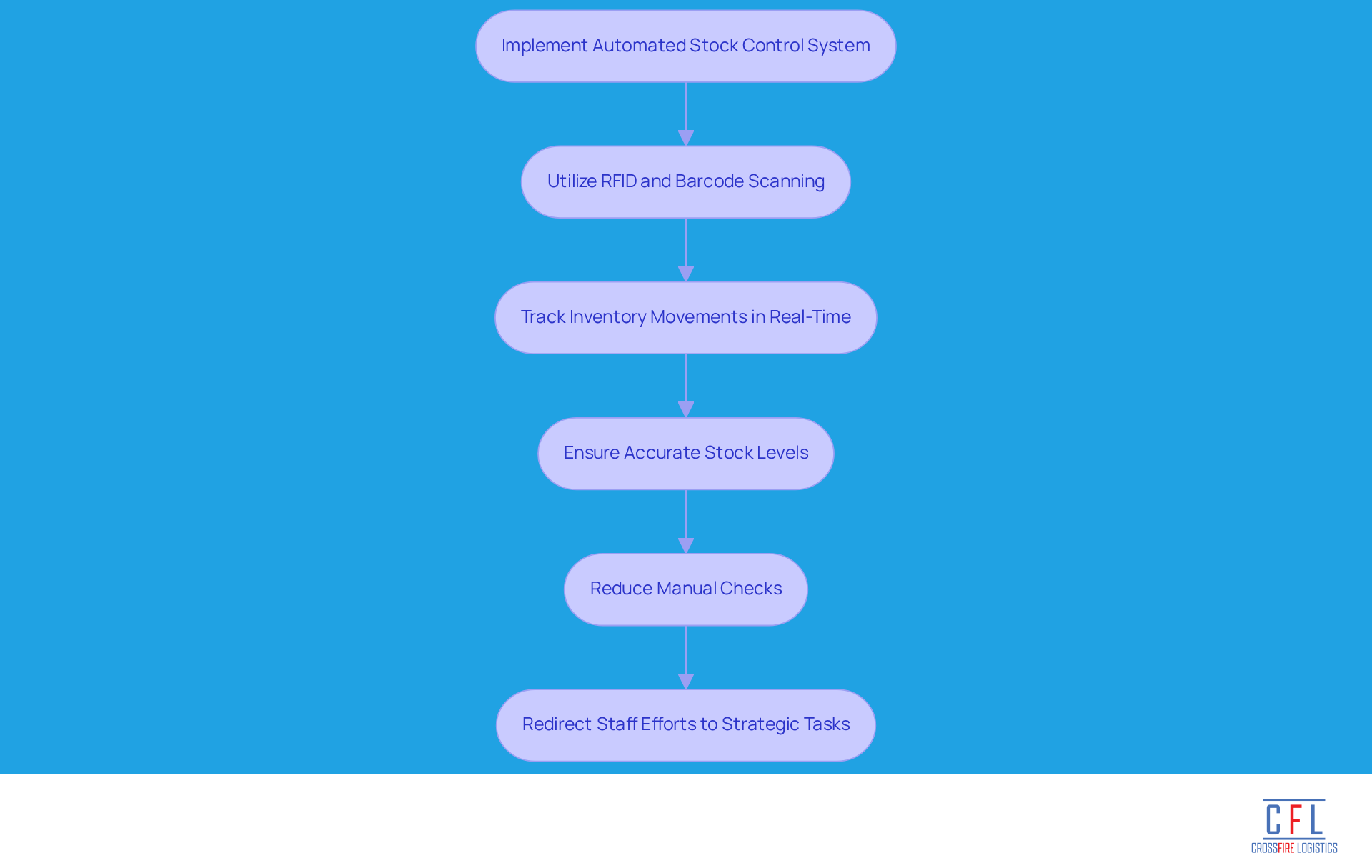

Automated Inventory Monitoring: Boosting Efficiency in Logistics Operations

Automated stock control systems play a crucial role in providing continuous oversight of supply levels. This capability enables logistics companies, such as Crossfire Logistics, to respond swiftly to fluctuations in demand.

These systems leverage advanced technologies like RFID and barcode scanning to track inventory movements in real-time. This ensures that stock levels remain accurate at all times. By automating these processes, the need for manual checks is significantly reduced. Consequently, staff can redirect their efforts towards more strategic tasks, thereby enhancing overall productivity.

Crossfire Logistics, known for its award-winning customer service and a decade-long track record in Hampton Roads, operates facilities in Newport News and Suffolk. The integration of automated stock control is essential for improving supply chain efficiency, ensuring that operations are consistently on-time and within budget.

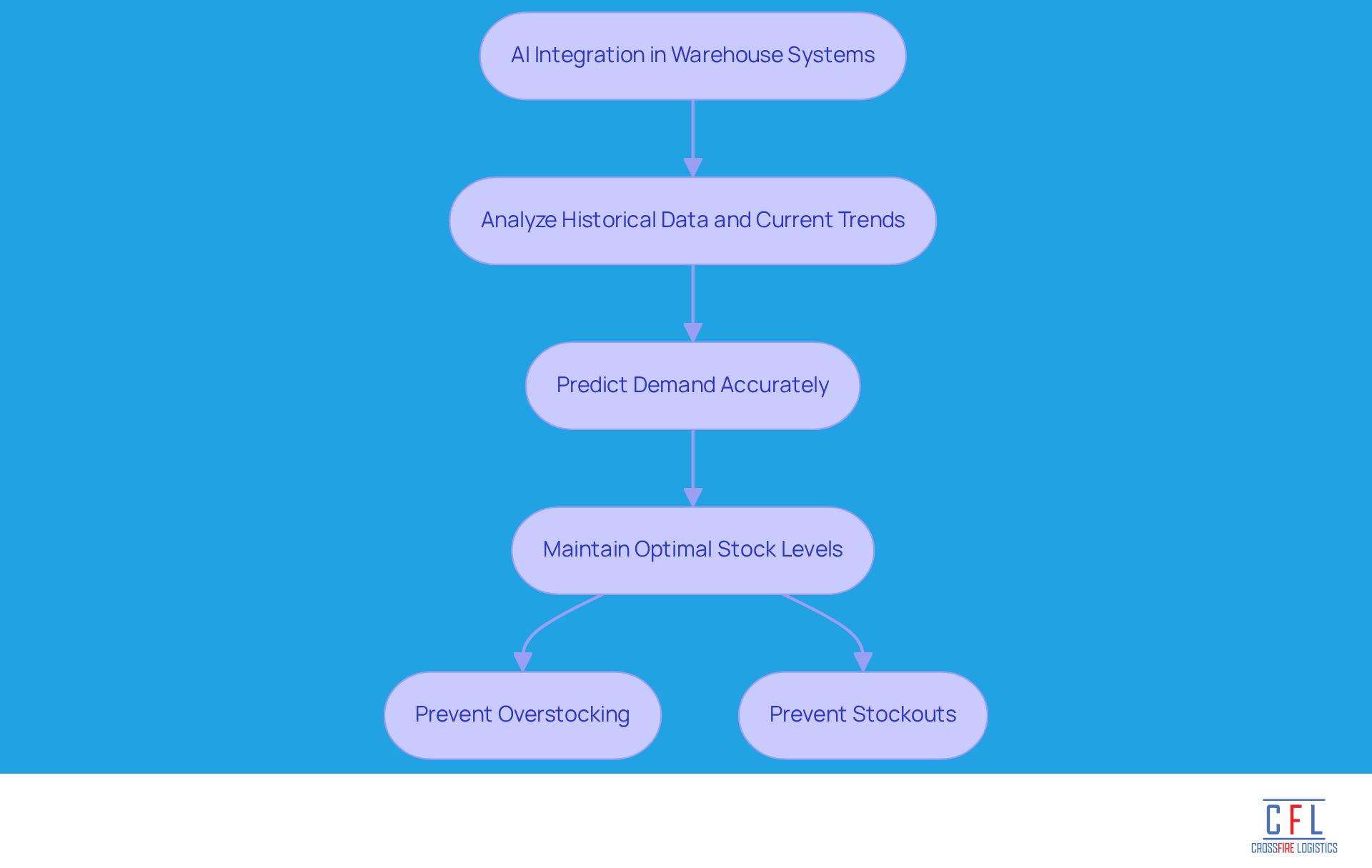

AI Integration: Streamlining Warehouse Management Systems for Better Stock Control

AI integration in warehouse operation systems enhances analytics and automation, resulting in significant improvements in automated stock control. By analyzing historical data alongside current trends, AI can more accurately predict demand. This capability enables supply chain firms to maintain optimal stock levels.

Such predictive analytics help prevent both overstocking and stockouts. As a result, products are readily available when needed, minimizing unnecessary holding costs.

Continuous Inventory Management: Ensuring Seamless Operations

Ongoing stock management is crucial for operational success. It involves regularly updating stock levels and monitoring stock movements. This proactive approach significantly reduces the risk of stockouts and overstock situations, enabling logistics firms to swiftly adapt to client demands.

A survey revealed that 45% of supply chain leaders see real-time stock visibility as a major challenge. This highlights the need for automated stock control systems that offer real-time updates. By utilizing these systems, businesses can maintain a steady flow of goods, which is vital for improving service delivery.

Real-time stock oversight not only boosts order accuracy but also enhances customer satisfaction by providing immediate visibility into stock levels. Experts from SEKO Logistics emphasize that effective stock management is key to minimizing disruptions and improving logistics operations.

The implementation of real-time tracking technologies allows companies to identify demand trends and adjust stock levels accordingly, ensuring operational efficiency. This capability is especially advantageous during peak demand periods, where timely restocking can prevent lost sales and foster customer loyalty.

Moreover, integrating real-time tracking with existing stock control systems is essential for improving efficiency and ensuring seamless operations. Overall, incorporating real-time updates into automated stock control processes is transformative, enhancing both efficiency and reliability in supply chain operations.

![]()

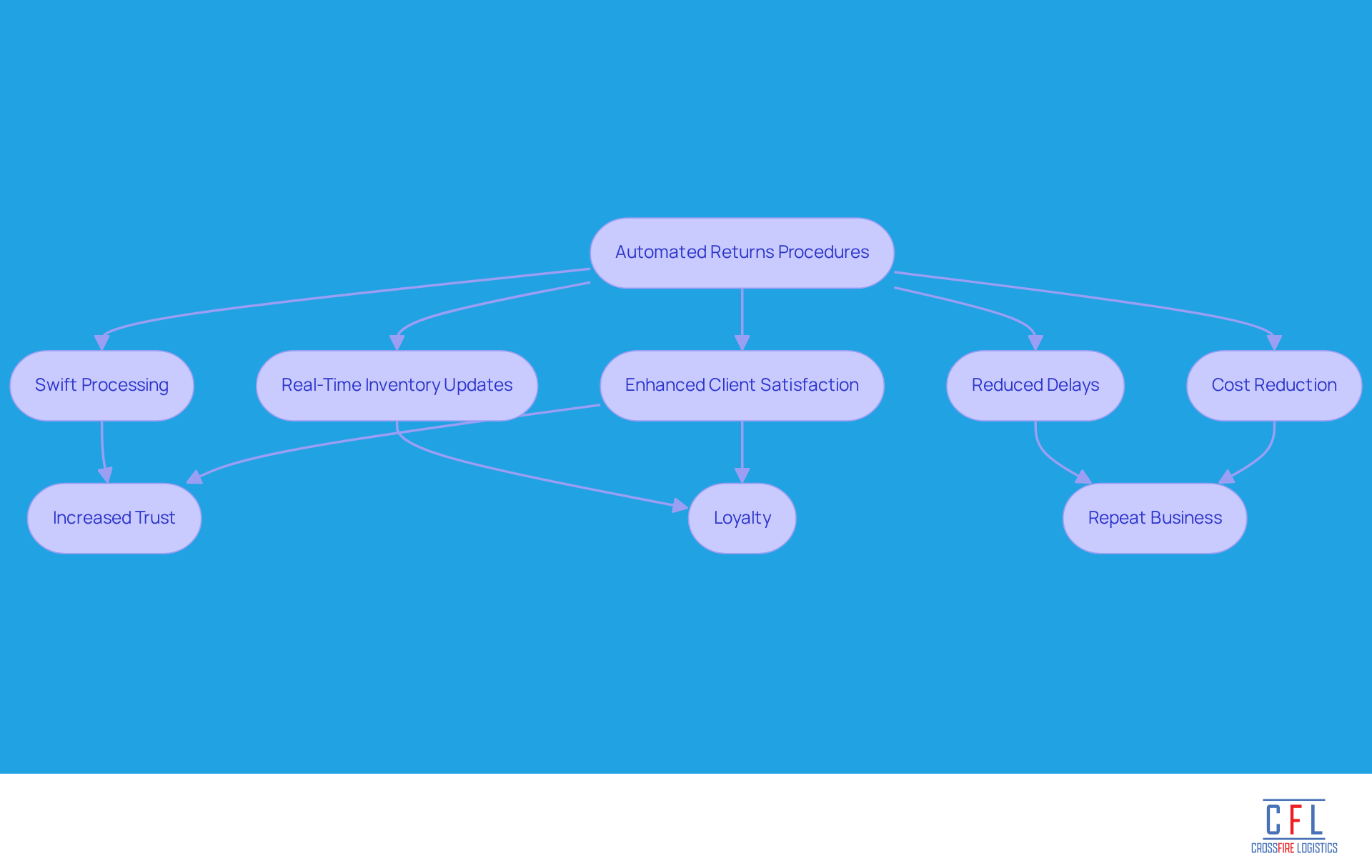

Optimized Returns Management: Enhancing Customer Satisfaction and Efficiency

Automated returns procedures significantly enhance the handling of returned goods, ensuring swift and efficient processing. By implementing automated tracking and real-time inventory updates, logistics companies can drastically reduce delays, leading to enhanced client satisfaction.

Projections indicate that 15.8% of annual sales will be returned in 2025, highlighting the critical need for efficient returns management. This efficiency not only enhances the client experience but also reduces costs related to returns processing, which in the U.S. alone amounted to $890 billion last year.

As indicated by industry experts, a streamlined returns process cultivates trust and loyalty among clients, ultimately driving repeat business. Moreover, automation in returns tracking facilitates quicker turnaround times, allowing companies to recover revenue by reintegrating products into stock more rapidly.

This strategic approach enhances operational workflows and positions businesses to succeed in a competitive market, where consumer expectations for seamless returns are higher than ever.

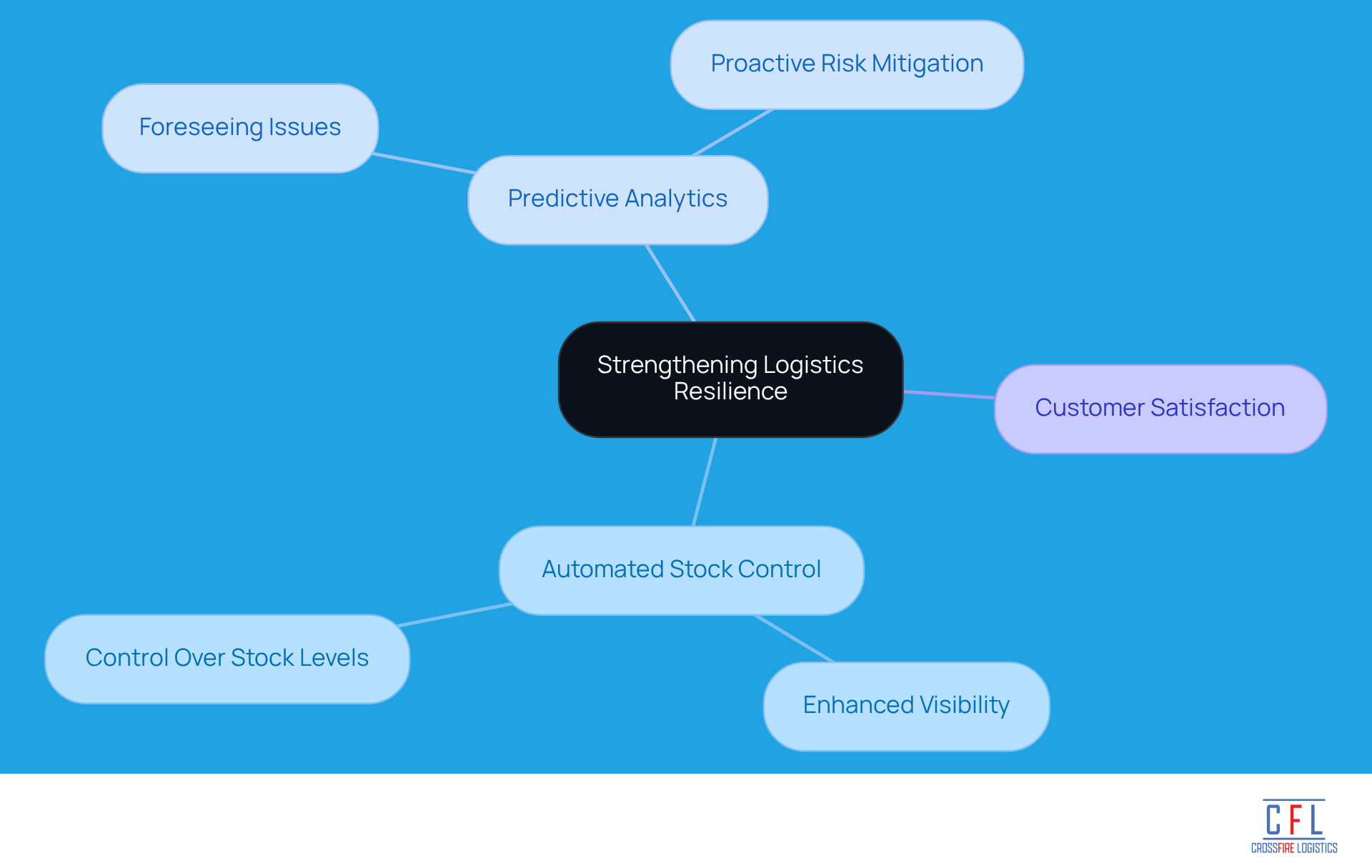

Reduced Supply Chain Disruptions: Strengthening Logistics Resilience

At Crossfire Logistics, the implementation of automated stock control systems significantly reduces supply chain disruptions. This is achieved by enhancing visibility and control over stock levels through automated stock control.

With our extensive 200,000 square feet of public and contract warehouse space in Hampton Roads, we leverage predictive analytics. This allows us to foresee potential issues and proactively address them, thereby mitigating risks. Such a strategic approach not only protects against unforeseen interruptions but also enhances overall operational effectiveness. As a result, we ensure that client needs are consistently satisfied.

Our dedication to integrity and excellence in supply chain management, combined with our award-winning customer service, establishes us as a leading partner for transportation solutions in the region. We invite businesses and individuals to partner with us, as we believe that robust collaborations are crucial for success in the field of supply chain management.

Improved Communication: Strengthening Supplier and Carrier Relationships

Effective communication channels among transportation firms, suppliers, and carriers are crucial for fostering collaboration and enhancing operational efficiency. Automated stock control systems that provide real-time updates and notifications ensure that all parties are informed about inventory levels and shipment statuses. This transparency builds trust and strengthens relationships, leading to smoother operations and improved service delivery.

In fact, 74% of supply chain executives are increasing their investments in automation and IoT technologies, recognizing their potential to enhance communication and coordination across the supply chain. As supply chain specialist Morten Johansen points out, companies that invest in adaptability and creativity will thrive in today's complex landscape.

By prioritizing real-time updates, companies can significantly improve logistics collaboration. This enables proactive problem-solving and timely decision-making, ultimately benefiting all stakeholders involved.

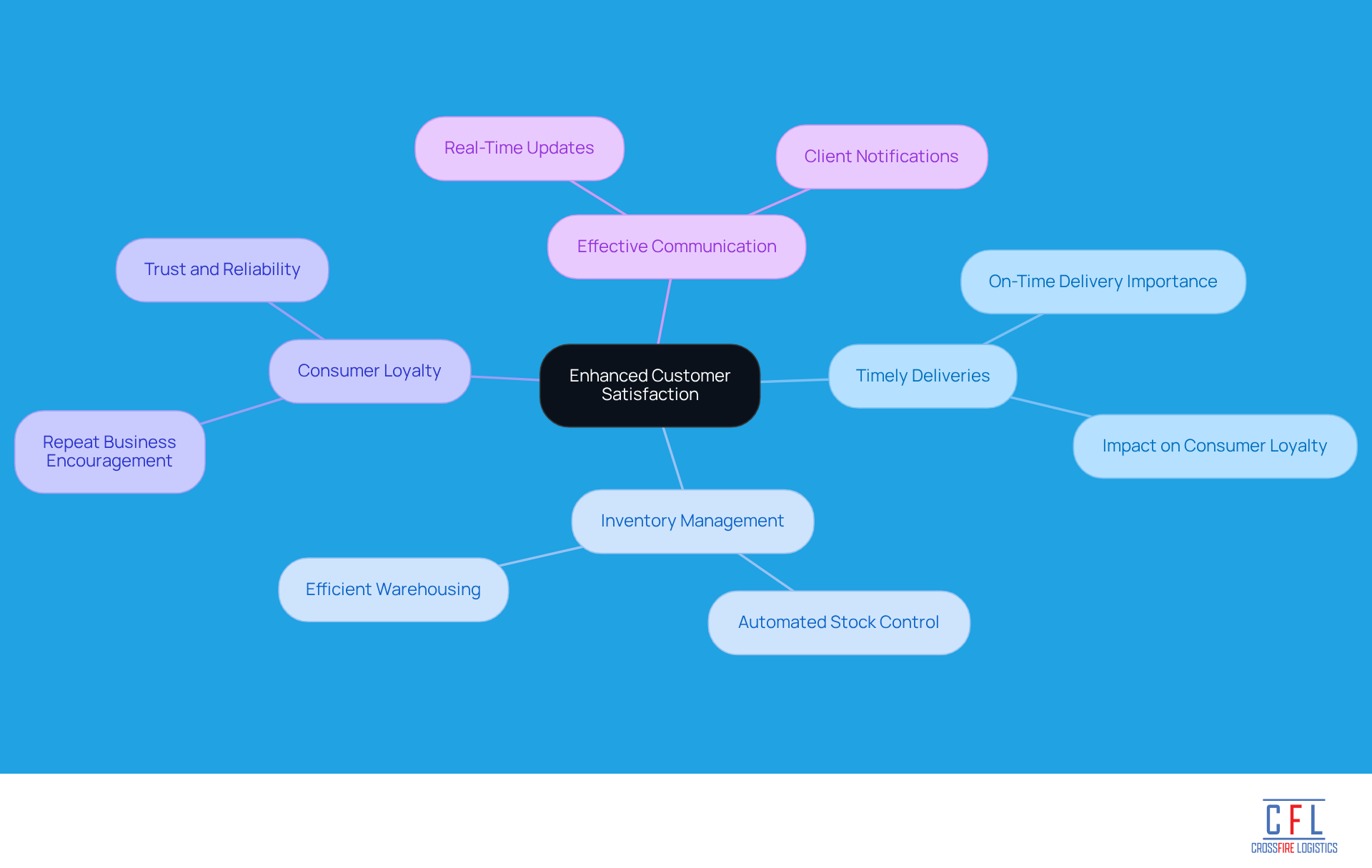

Enhanced Customer Satisfaction: Delivering Timely and Accurate Deliveries

Prompt and precise deliveries are crucial for enhancing client satisfaction, a goal made achievable through efficient inventory management. At Crossfire Logistics, our extensive warehousing facilities across Hampton Roads enable us to implement automated stock control processes, ensuring product availability. This significantly reduces lead times and improves order fulfillment rates.

This reliability aligns with client expectations and cultivates loyalty, encouraging repeat business. Industry insights reveal that 90% of consumers consider on-time delivery a critical factor in their shopping decisions, highlighting the direct link between timely deliveries and consumer loyalty.

Supply chain experts emphasize that ensuring on-time delivery is central to operations. This reinforces the idea that efficient inventory management is essential for maintaining a competitive advantage in the transportation landscape.

Moreover, effective communication is vital. At Crossfire Logistics, we prioritize keeping our clients informed at every stage of the delivery process, providing real-time updates and notifications. This approach not only enhances customer satisfaction but also strengthens confidence in our delivery services.

Strategic Advantages of Automated Stock Control: Driving Logistics Success

The strategic benefits of automated stock control significantly enhance supply chain success. These benefits include:

- Improved precision in stock monitoring.

- Reduced operational expenses.

- Enhanced efficiency in order fulfillment.

By leveraging technology to automate routine tasks, transportation firms can concentrate on strategic initiatives that boost competitiveness and customer satisfaction. Ultimately, integrating automated stock control into inventory management processes serves as a crucial driver of success in the logistics industry.

Conclusion

Automated stock control is a pivotal force in the logistics industry, fundamentally reshaping how businesses manage inventory and fulfill customer demands. By integrating advanced technology into stock management processes, companies can achieve enhanced operational efficiency, reduce errors, and ultimately improve customer satisfaction.

Key benefits of automated stock control include:

- Improved inventory accuracy

- Cost savings

- Optimized resource allocation

Real-time data acquisition and AI integration are crucial components that empower logistics firms to make informed decisions, adapt swiftly to market changes, and maintain optimal stock levels. Additionally, efficient returns management and improved communication with suppliers and carriers exemplify how automation can strengthen relationships and foster collaboration across the supply chain.

The importance of embracing automated stock control cannot be overstated. As the logistics landscape continues to evolve, adopting these technologies is essential for companies seeking a competitive edge. Organizations are encouraged to explore the implementation of automated systems, not only to enhance efficiency but also to drive long-term success and resilience in an ever-changing market.

Frequently Asked Questions

What is Crossfire Logistics' approach to inventory management?

Crossfire Logistics employs automated stock control to enhance operational efficiency, reduce manual errors, and improve visibility and control over stock levels.

How does automation benefit Crossfire Logistics?

Automation minimizes stock discrepancies, optimizes warehouse space usage, streamlines operations, and boosts overall productivity, allowing employees to focus on higher-value tasks.

What are the cost benefits of automated stock control?

Automated stock management leads to substantial cost savings by reducing excess storage fees and enhancing spend management, which drives profitability and operational resilience.

How does real-time data acquisition improve stock control?

Real-time data acquisition allows for continuous monitoring of stock levels, facilitating timely replenishment and reducing the risk of stockouts, thereby improving inventory accuracy.

What improvements in inventory accuracy have been reported with real-time data?

Companies leveraging real-time data have reported up to a 30% improvement in inventory accuracy.

What financial benefits can result from implementing real-time tracking and analytics?

Organizations implementing these systems have experienced a 15% increase in sales due to improved product availability and savings from reduced missed deliveries.

What challenges might companies face when implementing real-time data systems?

Challenges may include technology compatibility and scalability issues.

Why is data-driven decision-making important in logistics?

Data-driven decision-making enhances efficiency and customer satisfaction, allowing companies to react quickly to market changes and maintain a competitive edge.