Introduction

The logistics industry stands at a crucial juncture, where the demand for efficiency and adaptability is more urgent than ever. Modern supply chains are increasingly complex, and consumer expectations are evolving rapidly. Coordinators now face the challenge of implementing strategies that not only streamline operations but also enhance overall service delivery.

This article explores ten essential logistics and infrastructure strategies that coordinators can leverage to optimize their processes and prepare for the future.

How can these strategies transform logistics operations? What innovative practices will define success in 2025 and beyond?

Crossfire Logistics: Comprehensive Warehousing and Drayage Solutions

Crossfire Logistics offers a comprehensive suite of warehousing and drayage solutions tailored to meet the diverse needs of its clients. With over 200,000 square feet of strategically located warehouse space in Hampton Roads, the company guarantees efficient handling of goods, particularly for clients utilizing the Ports of Norfolk. Their expert drayage services enable swift transport of containers between ports and warehouses, significantly reducing delays and enhancing overall supply chain efficiency. This integrated approach allows companies to optimize their logistics and infrastructure, ensuring timely deliveries while minimizing costs.

Key features include:

- General and Contract Warehousing: Flexible storage solutions customized to client specifications, accommodating varying inventory needs.

- Drayage Services: Streamlined transport of goods from ports to warehouses, effectively reducing transit times and improving supply chain responsiveness.

- Cross-Dock/Transload Services: Efficient transfer of goods between various transport modes, enhancing supply chain flexibility.

- E-commerce Fulfillment: Efficient processes for managing online orders, ensuring rapid delivery and customer satisfaction.

Looking ahead to 2025, the average expenses of drayage operations are projected to reflect the growing demand for effective supply chain solutions. Experts in the logistics and infrastructure sector emphasize that efficient drayage solutions not only improve operational effectiveness but also contribute to overall cost reductions, making them a vital component of modern logistics and infrastructure strategies. Current trends indicate a shift towards increasingly automated and intelligent warehousing solutions, with approximately 4.28 million warehouse robots expected to be deployed globally by 2025. This further underscores the importance of integrating drayage services into comprehensive supply chain frameworks that focus on logistics and infrastructure.

E-commerce Fulfillment: Streamlining Order Processing and Delivery

E-commerce fulfillment plays a crucial role in modern logistics, and Crossfire Logistics stands out by providing tailored solutions that enhance order processing and delivery. By leveraging advanced technology and streamlined workflows, the company ensures that orders are processed swiftly and accurately, which is vital for maintaining customer satisfaction in a competitive market.

Key strategies include:

- Automated Order Processing: By utilizing technology, Crossfire reduces manual errors and accelerates fulfillment times. Automated systems can complete tasks in under two minutes, significantly improving order accuracy and minimizing the risk of errors.

- Real-Time Inventory Management: This strategy ensures accurate stock levels, preventing stockouts and overstock situations, which in turn enhances order accuracy and customer satisfaction.

- Efficient Shipping Solutions: Crossfire partners with reliable carriers to provide timely deliveries. This is increasingly important as customer expectations for shipping speed rise, influenced by standards set by major retailers.

- Sustainable Practices: The company adopts eco-friendly packaging and energy-efficient facilities to meet the growing consumer demand for sustainability. This approach not only addresses environmental concerns but also enhances brand reputation and customer loyalty.

- Data-Driven Decision Making: By utilizing analytics and stock forecasting tools, Crossfire optimizes operations to ensure the right products are available at the right time. This ultimately improves the order-to-delivery cycle, helping businesses anticipate market trends and adjust their inventory accordingly.

Through the integration of these strategies, Crossfire enhances operational efficiency and positions itself as a leader in the evolving e-commerce landscape, ready to meet the challenges of 2025 and beyond.

Cross-Dock and Transload Solutions: Enhancing Freight Handling Efficiency

Cross-dock and transload solutions play a crucial role in improving freight handling efficiency. At Crossfire Logistics, we leverage these strategies to minimize storage time and reduce handling costs, which facilitates faster turnaround times in the supply chain. Our extensive warehousing and drayage services for the Ports of Norfolk are tailored to support these initiatives, backed by our decade-long track record and award-winning customer service.

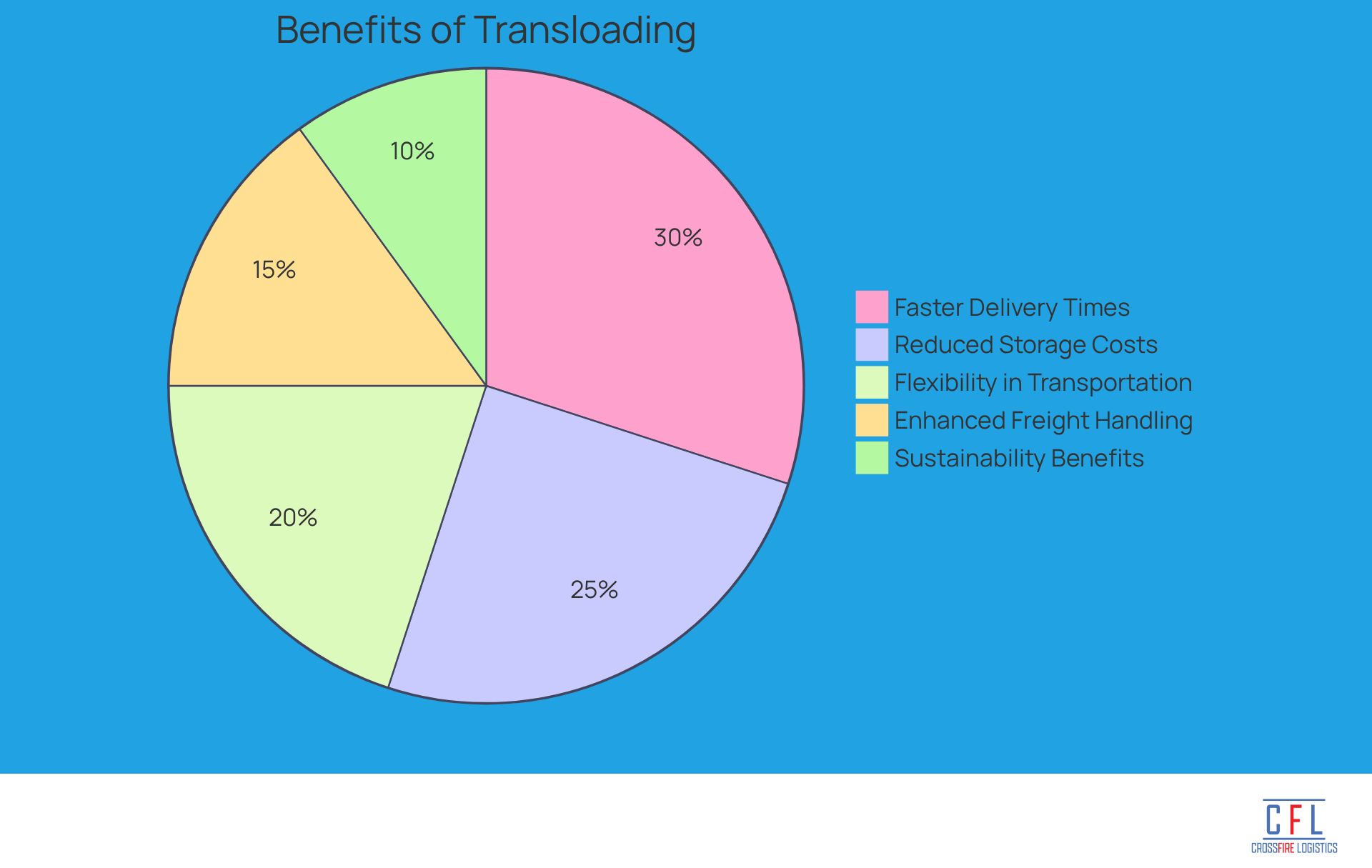

Key Benefits:

- Reduced Storage Costs: By transferring goods directly from inbound to outbound transport, we minimize storage needs. This approach can lead to average storage cost reductions of up to 40% for businesses utilizing these solutions.

- Faster Delivery Times: Streamlined processes ensure that products move swiftly through the supply chain, enhancing overall delivery speed and reliability.

- Flexibility in Transportation: Transloading allows for the effective transfer of goods between various modes of transport, optimizing operational processes and enabling quick adjustments to evolving demands.

- Enhanced Freight Handling Efficiency: By integrating transloading with our warehousing operations, Crossfire achieves better control over cargo flow and inventory accuracy, ultimately improving final-mile performance. This integration supports successful freight handling strategies that minimize delays and enhance routing efficiency.

- Sustainability Benefits: Transloading aids sustainability goals by reducing fuel consumption and carbon emissions through the use of rail for long-haul segments and shipment consolidation.

Integrating these strategies can significantly enhance the operational efficiency of supply chain coordinators in terms of logistics and infrastructure, ensuring competitiveness in a rapidly changing industry. With Crossfire, you can depend on our comprehensive solutions to meet your transportation needs.

Inventory Management Techniques: Ensuring Accuracy and Availability

Efficient stock management methods are essential for ensuring precision and accessibility in logistics and infrastructure operations. Crossfire Logistics employs various best practices to optimize stock management and enhance operational efficiency.

Key techniques include:

-

Cycle Counting: This method involves regularly scheduled counts to maintain inventory accuracy and identify discrepancies. Achieving a 99.9% accuracy rate in stock through cycle counting is feasible by implementing clear policies and effectively categorizing items. Regular audits of the cycle counting process help pinpoint areas for improvement, ensuring that discrepancies are addressed promptly. As Grant Ludema notes, "Cycle counting is not just a mundane task; it's a strategic initiative that can save time and money."

-

Just-In-Time Stock Management: This approach minimizes excess goods by aligning stock levels closely with demand, thereby reducing holding costs and improving cash flow. By synchronizing stock delivery with production schedules, companies can enhance operational efficiency and adaptability to market changes through improved logistics and infrastructure.

-

Automated Tracking Systems: Utilizing technology such as barcode and RFID systems allows for real-time monitoring of stock levels, ensuring timely replenishment and reducing manual errors. Automation in logistics and infrastructure not only streamlines operations but also enhances accuracy, as demonstrated by a significant reduction in human error through the use of these technologies.

The significance of cycle counting in achieving stock precision cannot be overstated. Experts emphasize that effective cycle counting is a strategic initiative that helps prevent stockouts and prepares companies for future growth. In fact, up to 60% of retailers' stock records may be flawed, highlighting the essential need for robust stock management practices. By prioritizing high-value items for more frequent counts and employing advanced technologies, organizations can significantly enhance their inventory accuracy and overall supply chain performance. Additionally, developing a cycle counting schedule that focuses on high-value items can further improve operational efficiency.

Technology Integration: Optimizing Logistics Operations

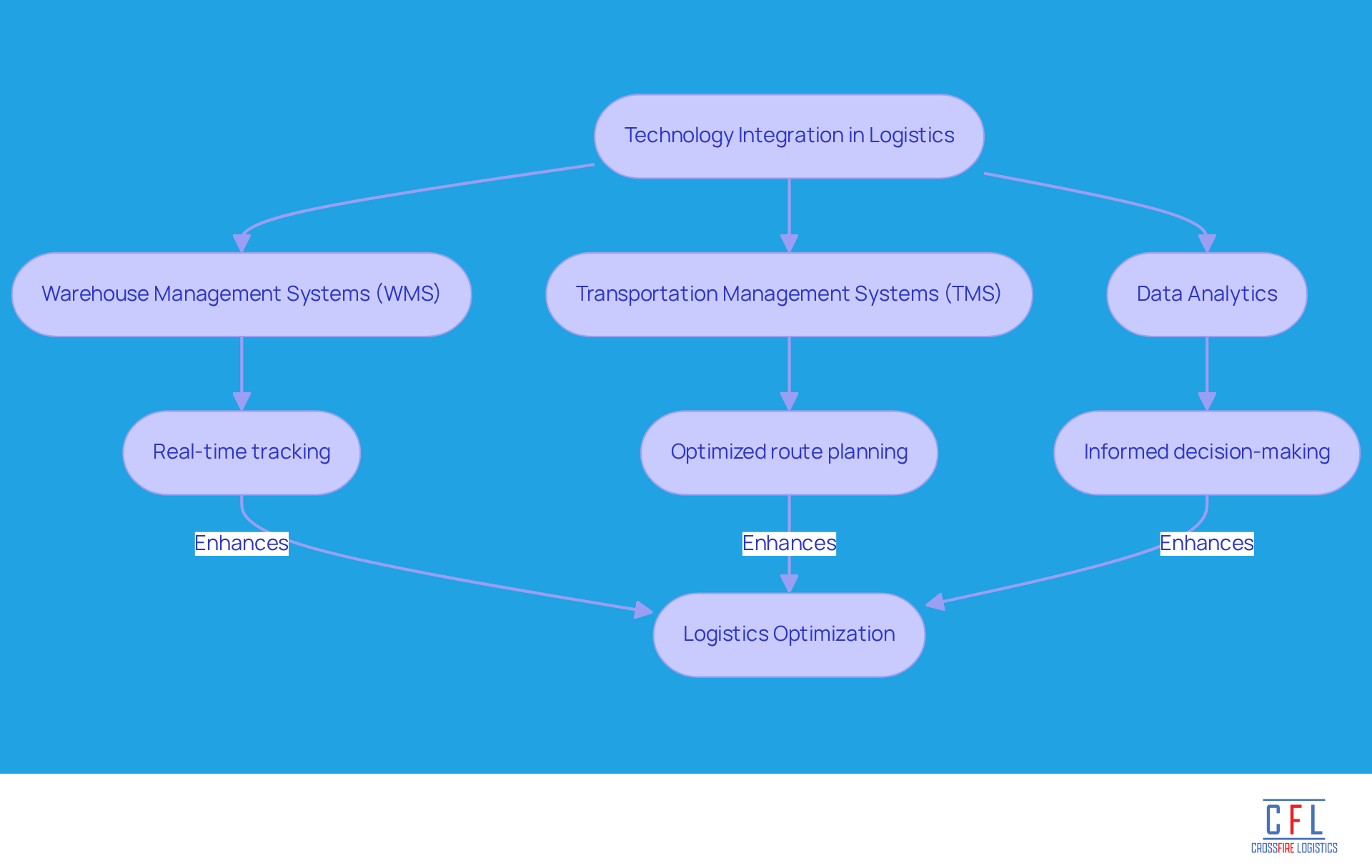

The transformation of logistics and infrastructure through technology integration is enabling companies like Crossfire Logistics to improve their supply chain processes and elevate service delivery. By embracing advanced technologies, supply chain coordinators can significantly enhance the logistics and infrastructure, improving visibility, efficiency, and responsiveness across their operations.

Key technologies driving this transformation include:

- Warehouse Management Systems (WMS): These systems streamline inventory management and order fulfillment, enabling real-time tracking and improved accuracy. With over 90% of warehouses expected to adopt WMS by 2025, and the global warehouse management system market projected to grow from USD 3.45 billion in 2020 to USD 9.11 billion by 2025, their role in enhancing operational efficiency is undeniable.

- Transportation Management Systems (TMS): TMS solutions optimize route planning and carrier selection, leading to substantial cost reductions. As transportation expenses continue to rise, efficient TMS implementation is essential for maintaining a competitive edge. As FedEx highlights, "We’re always striving to utilize technology trends in transportation and provide a superior experience for the businesses we assist."

- Data Analytics: Leveraging data analytics allows companies to make informed decisions that enhance operational performance. By utilizing predictive analytics, businesses can forecast demand and optimize labor deployment, ultimately improving service levels and reducing costs.

While the integration of these technologies simplifies supply chain processes, it is essential to acknowledge the challenges in logistics and infrastructure faced by the warehousing industry, such as space shortages and resistance to change. Addressing these issues will further position companies to respond swiftly to market changes and customer demands. As industry leaders stress, efficient warehouse management systems are crucial for attaining operational excellence and enhancing profitability in today's fast-paced supply chain environment.

Sustainable Practices: Implementing Eco-Friendly Logistics Solutions

Sustainable practices in logistics and infrastructure are becoming essential in supply chain management, with Crossfire leading the way in implementing eco-friendly solutions that significantly reduce environmental impact. By adopting these practices, companies not only enhance their brand reputation but also comply with increasing regulatory requirements.

Key sustainable practices include:

- Green Warehousing: This involves utilizing energy-efficient technologies and sustainable materials in warehouse operations. A shift towards recyclable or biodegradable materials can lead to substantial reductions in energy consumption and waste.

- Eco-Friendly Transportation: Strategies such as load consolidation and route optimization are vital for minimizing carbon emissions. Companies that leverage data-driven routing decisions can reduce transportation emissions by 20-30%, while also achieving significant fuel savings. The integration of real-time tracking and monitoring further enhances these efforts, allowing for proactive adjustments that contribute to sustainability goals.

- Waste Reduction Initiatives: Logistics operations are increasingly focused on minimizing packaging waste and promoting recycling. The trend of right-sizing packages to match product dimensions is becoming crucial in logistics and infrastructure, as it reduces material waste and lowers fuel consumption.

As the supply chain sector evolves, incorporating these eco-friendly strategies is expected to play a pivotal role in decreasing carbon emissions by 2025, aligning with global sustainability objectives. Additionally, the anticipated role of carbon crediting will be critical for businesses aiming to meet their sustainability goals. Companies that adopt these practices will not only contribute to environmental conservation but also position themselves favorably in a market increasingly driven by sustainability.

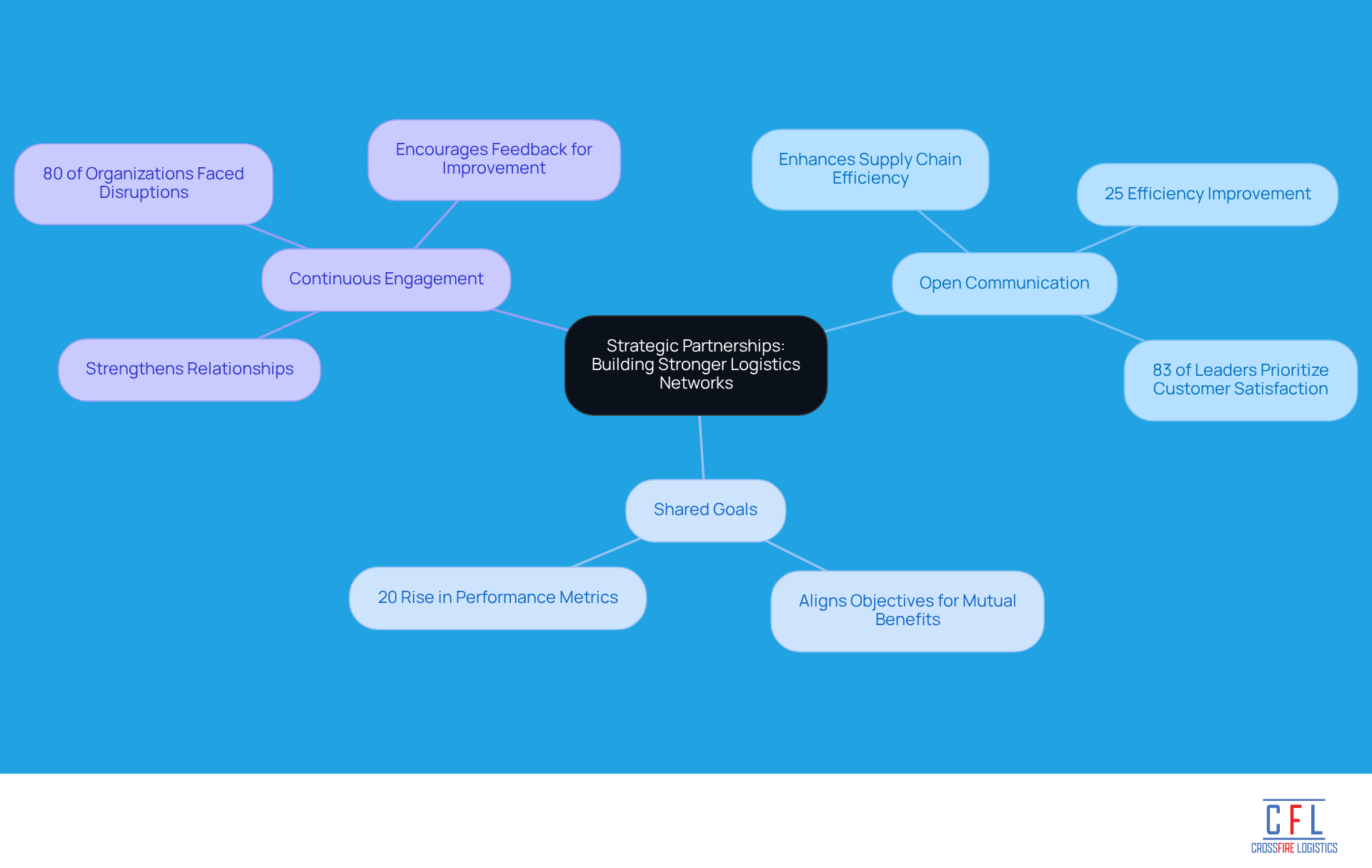

Strategic Partnerships: Building Stronger Logistics Networks

Strategic collaborations are essential for enhancing logistics and infrastructure as well as improving service delivery. Crossfire Logistics prioritizes collaboration with various stakeholders, including suppliers, carriers, and technology providers, to cultivate a more efficient distribution ecosystem. Our commitment to working with reliable transportation partners is key to our success, as we focus on mutual benefits and shared goals.

Key strategies for building effective partnerships include:

- Open Communication: Establishing clear lines of communication fosters trust and collaboration, which are essential for addressing challenges and enhancing operational efficiency. Statistics suggest that organizations with effective communication practices can enhance supply chain network efficiency by as much as 25%. Furthermore, 83% of supply chain leaders prioritize customer satisfaction, underscoring the importance of effective communication.

- Shared Goals: Aligning objectives with partners ensures mutual benefits and success, creating a unified approach to logistics challenges. This alignment can result in a 20% rise in overall performance metrics, as observed in our logistics and infrastructure collaborations with reliable carriers who share our dedication to quality.

- Continuous Engagement: Regular interactions with partners strengthen relationships and facilitate proactive problem-solving, which is crucial in a landscape where nearly 80% of organizations faced supply chain disruptions in the past year. Supply chain disruptions occur on average every 3.7 years, lasting over a month, highlighting the need for ongoing engagement. At Crossfire Logistics, we encourage our carriers to offer feedback and suggestions to assist us in enhancing our offerings.

Our extensive supply chain solutions, encompassing warehousing, transportation, and e-commerce offerings, have gained the confidence of industry leaders. Companies that partner with us benefit from our extensive experience and commitment to excellence. As Dwight D. Eisenhower noted, "The value of planning is high, however, as defining objectives drives long-term strategy." By applying these strategies, coordinators can significantly enhance their logistics and infrastructure networks, which results in better service delivery and operational resilience, supported by our comprehensive supply chain solutions tailored to meet diverse needs. If you are interested in collaborating with Crossfire, please reach out to us to discuss how we can work together for mutual success.

Risk Management Strategies: Safeguarding Supply Chain Operations

Effective risk management strategies are essential for safeguarding supply chain operations. Crossfire Logistics employs various techniques to identify and mitigate risks that could disrupt supply chain processes.

Key strategies include:

-

Supply Chain Mapping: This involves visualizing the supply chain to pinpoint vulnerabilities and potential risks. By enhancing visibility and predictiveness, organizations can better understand their dependencies and identify areas that require additional oversight.

-

Contingency Planning: Developing backup plans is crucial for addressing potential disruptions, such as supplier failures or transportation delays. Successful examples in supply chain management demonstrate that organizations with well-defined contingency plans can respond more efficiently to unforeseen challenges, thereby reducing downtime and maintaining service standards. For instance, organizations that implemented robust contingency plans reported significantly lower impacts from disruptions.

-

Regular Risk Assessments: Continuously evaluating risks and implementing measures to minimize their impact is vital. This proactive approach not only enhances resilience but also aligns with the increasing emphasis on organizational agility in the face of disruptions. Notably, 80% of organizations faced supply chain disruptions in 2024, highlighting the necessity for ongoing risk assessments.

Industry leaders assert that effective contingency planning is not just a reactive measure; it is a strategic necessity. As Simon Sølvsten, Head of Organizational Resilience Research, stated, "Organizations need to proactively anticipate, mitigate, and manage a growing range of potential disruptions." This proactive mindset is increasingly recognized as essential for maintaining operational continuity and achieving long-term success in supply chain management.

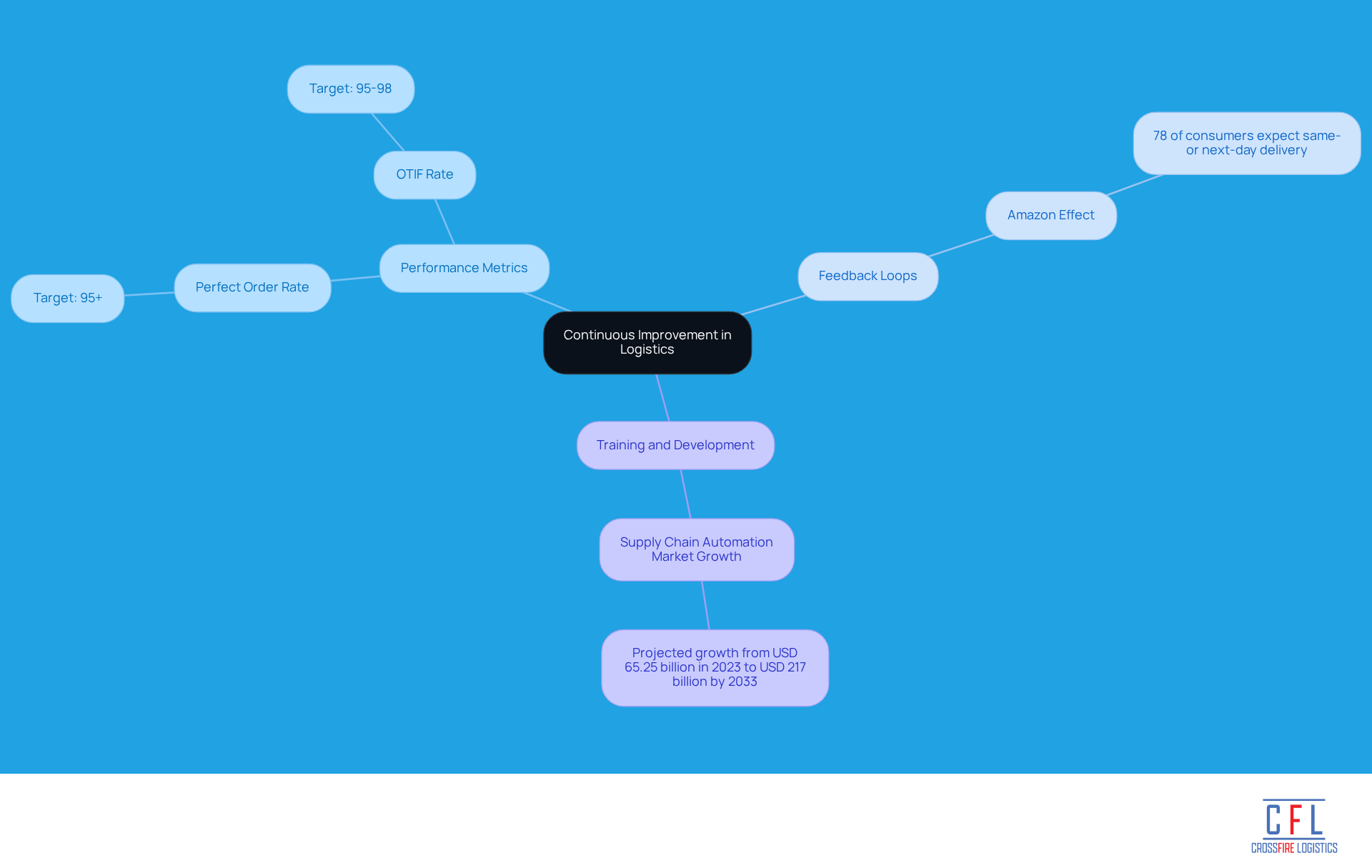

Continuous Improvement: Adapting Logistics Strategies for Future Success

Ongoing enhancement is a cornerstone of supply chain management, empowering companies to refine their strategies for sustained success. Crossfire Logistics fosters a culture of ongoing enhancement in logistics and infrastructure, ensuring that operations are optimized to meet the dynamic needs of clients.

Key practices for continuous improvement include:

-

Performance Metrics: Establishing key performance indicators (KPIs) is essential for measuring success and pinpointing areas for enhancement. Top-tier supply chain firms target a Perfect Order Rate of 95% or above, with many pursuing an On-Time In-Full (OTIF) rate of 95-98%, demonstrating their dedication to operational excellence.

-

Feedback Loops: Implementing robust systems to gather feedback from clients and employees is crucial for driving improvements. This approach not only enhances service quality but also aligns operations with customer expectations shaped by the 'Amazon effect,' where 78% of consumers expect same- or next-day delivery.

-

Training and Development: Investing in employee training ensures teams are equipped with the latest skills and knowledge, fostering a workforce capable of adapting to emerging technologies and methodologies. As automation and AI enhance logistics and infrastructure in supply chain management, continuous learning is vital for maintaining a competitive edge. The supply chain automation market is anticipated to expand from USD 65.25 billion in 2023 to USD 217 billion by 2033, highlighting the significance of adopting these advancements.

The effect of these performance metrics on supply chain success rates is significant. Companies that effectively leverage data analytics and real-time visibility can reduce supply chain disruptions and improve operational efficiency, ultimately enhancing customer satisfaction. In 2025, supply chain leaders will increasingly prioritize these metrics, with 83% ranking customer satisfaction as their top KPI, underscoring the critical role of performance measurement in achieving operational excellence. As Aaron Keeports, Content Marketing Manager, states, "Successful companies are those that embrace the latest trends and challenges in the logistics industry and use technology effectively to capitalize on them.

Conclusion

The logistics and infrastructure landscape is evolving rapidly, making effective strategies essential for coordinators who aim to enhance operational efficiency and meet the demands of 2025. By integrating comprehensive warehousing solutions, streamlined e-commerce fulfillment processes, and advanced technology, companies can create a resilient supply chain that not only meets but exceeds customer expectations. The focus on sustainability, strategic partnerships, and continuous improvement underscores the need for a holistic approach in logistics management.

Key strategies such as:

- Automated order processing

- Real-time inventory management

- Risk mitigation techniques

are vital components for success. Embracing technology—from warehouse management systems to data analytics—empowers coordinators to optimize operations and improve service delivery. Additionally, fostering strong partnerships and maintaining open communication with stakeholders are crucial for navigating the complexities of the logistics environment.

As the industry prepares for future challenges, it is imperative for logistics coordinators to adopt these strategies and remain agile. By prioritizing innovation and sustainability, organizations can safeguard their operations and position themselves as leaders in the logistics sector. The journey toward operational excellence is ongoing, and embracing these practices will ensure that companies are well-equipped to thrive in an increasingly competitive landscape.

Frequently Asked Questions

What services does Crossfire Logistics offer?

Crossfire Logistics offers a comprehensive suite of warehousing and drayage solutions, including general and contract warehousing, drayage services, cross-dock/transload services, and e-commerce fulfillment.

How does Crossfire Logistics enhance supply chain efficiency?

The company enhances supply chain efficiency through expert drayage services that facilitate swift transport of containers between ports and warehouses, reducing delays and optimizing logistics.

What are the benefits of Crossfire's warehousing solutions?

Crossfire's warehousing solutions provide flexible storage options tailored to client specifications, accommodating varying inventory needs and ensuring efficient handling of goods.

What is the role of e-commerce fulfillment in Crossfire Logistics?

E-commerce fulfillment at Crossfire Logistics focuses on streamlining order processing and delivery using automated systems, real-time inventory management, and efficient shipping solutions to enhance customer satisfaction.

How does Crossfire Logistics ensure accurate order processing?

Crossfire utilizes automated order processing technology to reduce manual errors and accelerate fulfillment times, ensuring orders are processed swiftly and accurately.

What strategies does Crossfire use for inventory management?

Crossfire employs real-time inventory management to maintain accurate stock levels, preventing stockouts and overstock situations, which enhances order accuracy and customer satisfaction.

What sustainability practices does Crossfire Logistics implement?

Crossfire adopts eco-friendly packaging and energy-efficient facilities to meet consumer demand for sustainability, which also enhances brand reputation and customer loyalty.

What are the key benefits of cross-dock and transload solutions provided by Crossfire?

Key benefits include reduced storage costs, faster delivery times, flexibility in transportation, enhanced freight handling efficiency, and sustainability benefits through reduced fuel consumption and carbon emissions.

How does Crossfire Logistics support sustainability goals?

Crossfire supports sustainability goals by using transloading to reduce fuel consumption and carbon emissions, particularly by utilizing rail for long-haul segments and consolidating shipments.

What future trends are anticipated in the logistics sector according to the article?

Future trends include a growing demand for effective supply chain solutions, increased automation in warehousing, and the deployment of approximately 4.28 million warehouse robots globally by 2025.