Introduction

In the fast-paced logistics sector, efficiently managing warehouse operations and supply chains has become increasingly critical. Businesses are under pressure to meet rising consumer demands, prompting the need for strategies that enhance operational efficiency, reduce costs, and improve customer satisfaction. This article explores ten key strategies that can transform warehouse management practices. It provides insights into how companies can adapt to evolving market conditions while leveraging technology and sustainability.

What challenges might organizations face in implementing these strategies? How can they ensure a seamless transition towards more effective supply chain management?

Crossfire Logistics: Comprehensive Warehousing Solutions for Streamlined Supply Chain Management

Crossfire Logistics offers a comprehensive suite of warehousing solutions designed to streamline supply chain management. With over 200,000 square feet of strategically located storage space, the company specializes in:

- General and contract storage

- E-commerce fulfillment

- Cross-dock/transload solutions

These tailored services ensure efficient handling of goods and seamless operations, particularly for businesses utilizing the Ports of Norfolk. By managing the entire logistics process, Crossfire Logistics significantly enhances customer satisfaction through timely and accurate deliveries.

Recent trends indicate that over 90% of storage facilities are expected to adopt Warehouse Management Systems (WMS) by 2025, signaling a shift towards automation and improved operational efficiency. As logistics companies increasingly invest in advanced technologies, Crossfire's commitment to integrating innovative solutions positions it as a leader in the industry. The impact of warehouse space on logistics efficiency is substantial; effective utilization of storage capabilities is crucial for reducing costs and enhancing service levels.

In the competitive landscape of Hampton Roads, successful logistics companies are those that can adapt to changing demands. Crossfire Logistics exemplifies this flexibility, ensuring that clients benefit from enhanced operational capabilities and a robust logistical framework. As the logistics sector continues to evolve, the importance of strategic warehousing solutions will only grow, making Crossfire an essential partner for enterprises looking to optimize their supply chain operations.

Enhanced Operational Efficiency: Streamlining Processes Through Effective Warehouse Management

Effective storage management is crucial for enhancing operational efficiency, particularly as companies face increasing demands for speed and accuracy in 2025. Optimizing the layout of storage facilities serves as a foundational strategy that can lead to significant improvements in workflow and productivity. A well-crafted layout can reduce travel time for employees, simplify picking processes, and enhance space utilization, which is increasingly important due to rising storage costs.

Cross-docking plays a pivotal role in this optimization. By minimizing the need for long-term storage, cross-docking facilitates quicker product movement from inbound to outbound transportation, significantly reducing handling times. This method not only enhances throughput but also supports just-in-time inventory practices, essential for meeting customer expectations in today's fast-paced market. The Cross Docking Market is projected to reach USD 250.92 billion in 2025, underscoring its growing importance in logistics.

To optimize warehouse layout for efficiency, businesses should consider several key strategies:

- Zoning: Designate specific areas for different activities, such as receiving, storage, and shipping, to minimize congestion and improve workflow.

- Vertical Storage Solutions: Utilize vertical space with shelving and racking systems to maximize storage capacity without expanding the footprint.

- Technology Integration: Implement management systems that provide real-time data on inventory levels and order statuses, enabling better decision-making and resource allocation. Automation is also anticipated to lower labor expenses by 25-30%, making it a crucial factor for storage operations.

- Flexible Design: Create adaptable layouts that can evolve with changing business needs, such as seasonal fluctuations in inventory or shifts in product lines.

A notable example of effective cross-docking implementation is Grupo Eroski, which has achieved same-day deliveries for 80% of its goods through this strategy, demonstrating its practical application and effectiveness in real-world scenarios.

Incorporating these strategies not only improves operational efficiency but also positions storage facilities as strategic centers within the supply chain, capable of responding swiftly to market demands. As the logistics landscape continues to evolve, those who prioritize effective storage management are likely to gain a competitive edge. As Peter Drucker famously stated, 'What Gets Measured, Gets Managed,' highlighting the importance of monitoring and optimizing storage operations. Additionally, storage facilities must navigate challenges such as labor shortages and space constraints, which are critical factors in today's logistics environment.

Cost Reduction: Minimizing Expenses with Efficient Warehouse and Supply Chain Management

Effective warehouse and supply chain management can lead to significant cost savings. This is especially true when leveraging the comprehensive solutions offered by Crossfire Logistics. By optimizing inventory levels, reducing waste, and enhancing labor productivity, businesses can effectively lower their operational costs.

Crossfire Logistics stands out with its award-winning customer service and a decade-long track record, ensuring that your logistics needs are met on time and within budget. The implementation of technology, such as warehouse and supply chain management systems (WMS), further enhances visibility and control over inventory, driving down costs even more.

Regular audits and performance assessments, backed by the expertise of Crossfire Logistics, help identify areas for improvement. This process ensures that resources are utilized effectively, maximizing efficiency and cost-effectiveness.

Real-Time Inventory Visibility: Improving Accuracy and Responsiveness in Supply Chain Operations

Real-time inventory visibility is essential for improving accuracy and responsiveness in logistics operations. By leveraging advanced tracking technologies like RFID and barcoding, businesses can monitor inventory levels in real-time. This capability allows for quick, informed decision-making, helping to prevent stockouts and ensuring that inventory aligns with customer demand. As a result, service levels and customer satisfaction are enhanced.

At Crossfire Logistics, we offer comprehensive warehousing and drayage solutions tailored to the unique needs of the Hampton Roads area. Our services ensure that your supply chain operates efficiently and effectively.

![]()

Automation Benefits: Leveraging Technology for Improved Warehouse Management

Automation in storage management presents significant advantages, such as increased efficiency, reduced labor costs, and enhanced accuracy.

Technologies like automated guided vehicles (AGVs), robotic picking systems, and warehouse management systems (WMS) play a crucial role in streamlining operations. They minimize manual tasks and optimize workflows, addressing common logistical challenges.

By adopting these technologies, companies can boost productivity and achieve faster order fulfillment. This not only leads to operational improvements but also enhances customer satisfaction.

Enhanced Customer Satisfaction: Meeting Expectations Through Efficient Supply Chain Practices

Effective logistics practices significantly enhance customer satisfaction. Crossfire Logistics exemplifies this principle through its award-winning customer service and comprehensive warehouse and supply chain management solutions in Hampton Roads.

By ensuring timely deliveries, precise order fulfillment, and effective communication, Crossfire Logistics helps organizations meet and exceed customer expectations. Implementing customer feedback mechanisms and continuously improving processes based on client input further strengthens relationships and fosters loyalty.

A customer-centric approach, as demonstrated by Crossfire Logistics, is essential for long-term success in logistics.

Integration Capabilities: Ensuring Seamless Operations Across Supply Chain Systems

Integration capabilities are essential for ensuring seamless operations across logistics systems. By connecting various functions - such as inventory management, order processing, and transportation logistics - businesses can gain greater visibility and control over their operations.

At Crossfire Logistics, we provide comprehensive storage and logistics solutions from our 200,000 square feet of public and contract storage space in Hampton Roads. Our services are designed to enhance the efficiency of the distribution process.

Utilizing integrated software solutions facilitates real-time data sharing and collaboration among stakeholders. This leads to improved decision-making and enhanced operational efficiency.

Moreover, our commitment to building strategic partnerships further streamlines logistics and warehouse and supply chain management solutions, making your operations more effective.

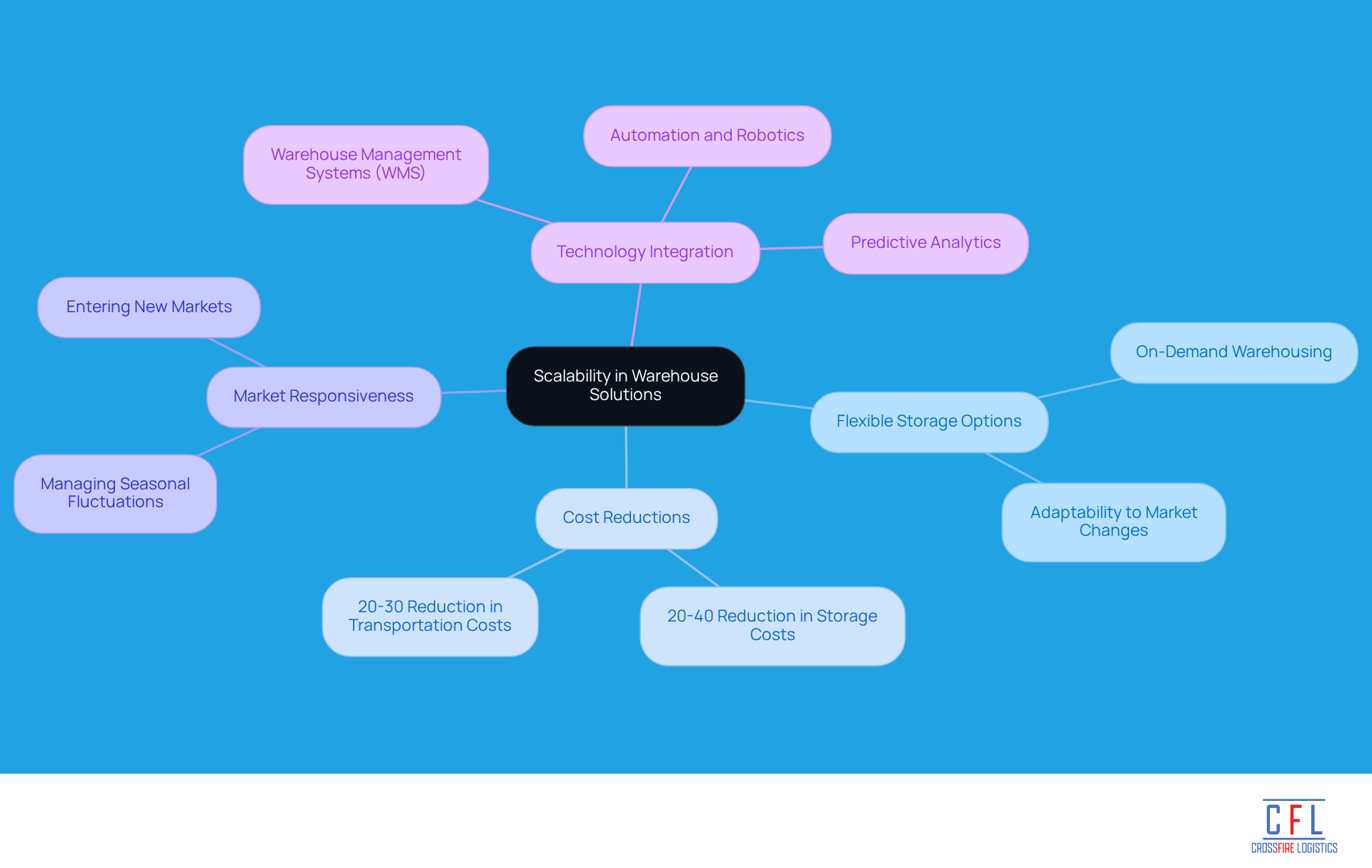

Scalability: Adapting Warehouse Solutions to Meet Growing Business Needs

Scalability in storage solutions is essential for companies aiming to adapt to changing demands and seize growth opportunities. By implementing flexible storage options and scalable logistics services in warehouse and supply chain management, businesses can adjust their operations smoothly, minimizing disruptions. This adaptability is particularly important for managing seasonal fluctuations and entering new markets.

For instance, companies that utilize on-demand warehousing can reduce storage costs by 20-40% and transportation expenses by 20-30%. This capability allows them to respond swiftly to market changes. Investing in scalable solutions in warehouse and supply chain management not only facilitates efficient growth but also guarantees consistent service quality, which is vital for maintaining customer satisfaction.

As the warehouse and supply chain management industry progresses, the integration of advanced technologies and flexible fulfillment strategies will be crucial in enhancing operational efficiency and profitability in 2025 and beyond.

Data Analytics: Enhancing Decision-Making in Warehouse and Supply Chain Management

Data analytics is essential for improving decision-making in warehouse and supply chain management by delivering actionable insights into operational performance. By monitoring key performance indicators (KPIs), organizations can identify trends, forecast demand accurately, and optimize inventory levels. KPIs such as order accuracy, inventory turnover, and lead time significantly influence strategic decisions, allowing companies to enhance service levels and reduce costs.

As we approach 2025, the influence of KPIs on logistics decision-making is increasingly significant. Organizations are relying more on data-driven insights to navigate a volatile market characterized by unpredictability. However, many companies face challenges with analytics and governance, which can impede timely decision-making. Advanced analytics tools empower companies to make proactive decisions, enabling quick adjustments to fluctuations in demand and operational disruptions. This agility is vital for maintaining competitiveness in a rapidly changing environment.

Furthermore, the effective use of KPIs can optimize storage operations by pinpointing inefficiencies and streamlining processes. For instance, monitoring KPIs related to labor productivity and space utilization can enhance workflow and resource allocation, ultimately boosting operational efficiency. Research from McKinsey highlights that integrating AI into supply chain operations could lower logistics costs by 5 to 20 percent, emphasizing the necessity of leveraging data analytics and KPIs. As companies increasingly adopt data analytics, incorporating KPIs into their decision-making frameworks will be crucial for driving performance and achieving strategic objectives in warehouse and supply chain management.

Sustainability Practices: Promoting Eco-Friendly Operations in Warehouse Management

Incorporating sustainability practices into storage management is essential for fostering eco-friendly operations and mitigating environmental impact. Key strategies include:

- Optimizing energy consumption

- Leveraging renewable resources

- Minimizing waste

For instance, warehouses that adopt energy-efficient lighting can achieve up to 40% savings on energy costs. Additionally, implementing waste reduction programs can lead to a 25% decrease in operational waste disposal costs. By embracing these sustainable practices, businesses not only enhance their brand reputation but also attract environmentally conscious customers. Notably, 72% of global consumers are willing to pay more for sustainable products.

Moreover, adherence to changing regulatory standards, such as the EU's new logistics law emphasizing corporate accountability, positions companies for long-term success. Ultimately, these eco-friendly operations contribute to a more resilient warehouse and supply chain management, which drives efficiency and customer loyalty in an increasingly competitive market.

Conclusion

Crossfire Logistics exemplifies the critical importance of effective warehouse and supply chain management in today’s competitive landscape. By implementing tailored strategies, businesses can optimize operations, enhance customer satisfaction, and achieve a sustainable competitive edge. The integration of advanced technologies, scalable solutions, and real-time inventory visibility are essential components for success in the logistics sector, rather than mere trends.

Key strategies highlighted include:

- Optimizing warehouse layouts

- Embracing automation

- Utilizing data analytics to drive decision-making

Each of these elements significantly contributes to reducing costs, improving efficiency, and consistently meeting customer expectations. Furthermore, the emphasis on sustainability practices reflects a growing awareness of environmental responsibilities within the industry, aligning operational goals with broader societal values.

As the landscape of warehouse and supply chain management continues to evolve, it is imperative for businesses to adopt these strategies proactively. By prioritizing efficiency, customer satisfaction, and sustainability, organizations can navigate the complexities of modern logistics and position themselves for long-term success. Embracing these practices will enhance operational capabilities and foster loyalty and trust among customers, which is essential in a rapidly changing market.

Frequently Asked Questions

What services does Crossfire Logistics offer for warehousing solutions?

Crossfire Logistics offers general and contract storage, e-commerce fulfillment, and cross-dock/transload solutions to streamline supply chain management.

How does Crossfire Logistics enhance customer satisfaction?

By managing the entire logistics process, Crossfire Logistics ensures timely and accurate deliveries, significantly enhancing customer satisfaction.

What is the significance of Warehouse Management Systems (WMS) in storage facilities?

Over 90% of storage facilities are expected to adopt WMS by 2025, indicating a trend towards automation and improved operational efficiency in logistics.

Why is effective storage management important for operational efficiency?

Effective storage management is crucial for meeting increasing demands for speed and accuracy, optimizing workflow, and reducing travel time for employees.

What role does cross-docking play in warehouse efficiency?

Cross-docking minimizes long-term storage needs, facilitating quicker product movement and significantly reducing handling times, which enhances throughput and supports just-in-time inventory practices.

What strategies can businesses implement to optimize warehouse layout for efficiency?

Businesses can implement zoning, vertical storage solutions, technology integration, and flexible design to improve workflow and maximize storage capacity.

How does technology integration benefit warehouse operations?

Technology integration provides real-time data on inventory levels and order statuses, enabling better decision-making and resource allocation, ultimately lowering labor expenses.

What challenges do storage facilities face in the current logistics environment?

Storage facilities must navigate challenges such as labor shortages and space constraints, which are critical factors in today's logistics landscape.

How can effective warehouse and supply chain management lead to cost savings?

By optimizing inventory levels, reducing waste, and enhancing labor productivity, businesses can lower operational costs significantly.

What is the importance of regular audits and performance assessments in logistics?

Regular audits and performance assessments help identify areas for improvement, ensuring effective resource utilization and maximizing efficiency and cost-effectiveness.