Introduction

Effective distribution chain management has become increasingly critical as businesses navigate a complex supply network. With numerous stakeholders involved - from suppliers to retailers - understanding and optimizing the flow of goods and information is essential for enhancing operational efficiency.

This article explores four best practices that streamline logistics operations, foster stronger communication, and leverage technology. These practices ultimately drive greater customer satisfaction.

As companies strive to adapt to shifting market dynamics and regulatory demands, identifying key strategies is vital. What can truly elevate their distribution chain management?

Understand the Supply Chain Landscape

Effective distribution chain management hinges on a comprehensive understanding of the supply network landscape. This landscape encompasses various stakeholders, including suppliers, manufacturers, distributors, and retailers. Recognizing the flow of goods and information among these entities is crucial for optimizing logistics operations.

-

Supply Chain Mapping: Developing a visual representation of your supply chain is vital. This mapping process identifies all parties involved and their respective roles, enabling the detection of potential bottlenecks and areas for improvement. Companies that have established detailed supply maps report significant enhancements in operational efficiency and responsiveness.

-

Market Dynamics: Staying attuned to market trends, customer demands, and competitive pressures is essential. This awareness allows enterprises to make proactive adjustments to their strategies, ensuring agility in a rapidly changing environment. Experts emphasize that understanding these dynamics is not just beneficial but necessary for maintaining a competitive edge.

-

Regulatory Environment: A comprehensive grasp of the regulations governing your industry is imperative. Compliance requirements can significantly impact logistics operations, and being well-informed helps mitigate risks associated with non-compliance.

By incorporating these components into their strategic planning, businesses can develop targeted strategies that significantly enhance their distribution chain management processes, ultimately resulting in improved efficiency and customer satisfaction.

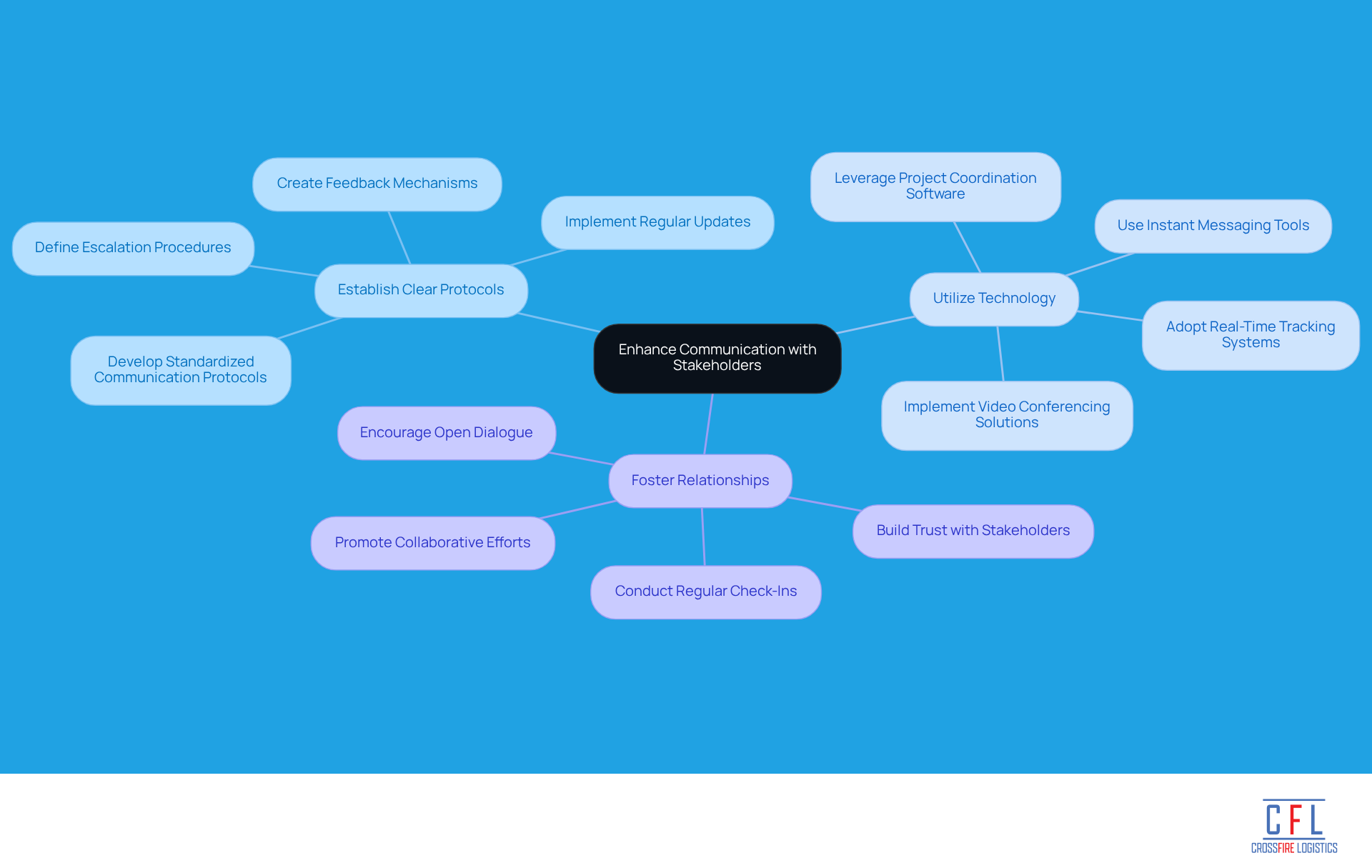

Enhance Communication with Stakeholders

To improve distribution network coordination, boosting communication with all stakeholders is essential. Here are some best practices:

- Establish Clear Protocols: Develop standardized communication protocols that define how information is shared among stakeholders. This includes regular updates, feedback mechanisms, and escalation procedures for addressing issues promptly.

- Utilize Technology: Leverage advanced communication tools such as project coordination software, instant messaging, and video conferencing to facilitate real-time interactions. This ensures that all parties remain aligned and informed, significantly reducing the risk of misunderstandings during disruptions.

- Foster Relationships: Build strong relationships with suppliers, carriers, and customers through regular check-ins and open dialogue. This approach not only enhances trust but also promotes collaboration, enabling stakeholders to work together effectively during challenging times.

By implementing these strategies, businesses can create a more cohesive and responsive distribution chain, ultimately improving operational efficiency and customer satisfaction.

Implement Effective Inventory Management Techniques

Efficient stock control is essential for ensuring product availability while minimizing expenses. Here are some effective practices to enhance your inventory management strategies:

-

Adopt Just-In-Time (JIT) Inventory: Implementing JIT inventory systems can significantly lower holding costs and reduce waste. This approach relies on accurate demand forecasting and strong supplier relationships, enabling businesses to respond quickly to market changes. Companies utilizing JIT have reported a 79% success rate in exceeding average industry performance, highlighting its effectiveness. Additionally, 79% of companies with high-performing supply chains achieve revenue growth that surpasses the average performance of their industries, showcasing the potential of JIT systems.

-

Employ Stock Control Software: Investing in advanced stock control software is crucial for gaining real-time visibility into inventory levels. These solutions automate reordering processes and analyze sales trends, allowing businesses to improve their stock management. By 2025, trends indicate an increasing reliance on software that integrates artificial intelligence and machine learning, enhancing forecasting accuracy and operational efficiency. This technological integration is expected to significantly improve stock management practices.

-

Conduct Regular Audits: Frequent stock audits are vital for identifying discrepancies and assessing stock levels. This practice ensures that stock records remain accurate, helping to maintain optimal levels and mitigate the risk of shortages. With 74% of companies experiencing shipment delays, maintaining precise stock records is more critical than ever. As Michael Korda suggests, examining weaknesses in stock control can uncover hidden opportunities for improvement.

By implementing these techniques, companies can significantly enhance their stock control practices, leading to improved distribution chain management, greater distribution efficiency, and enhanced customer satisfaction.

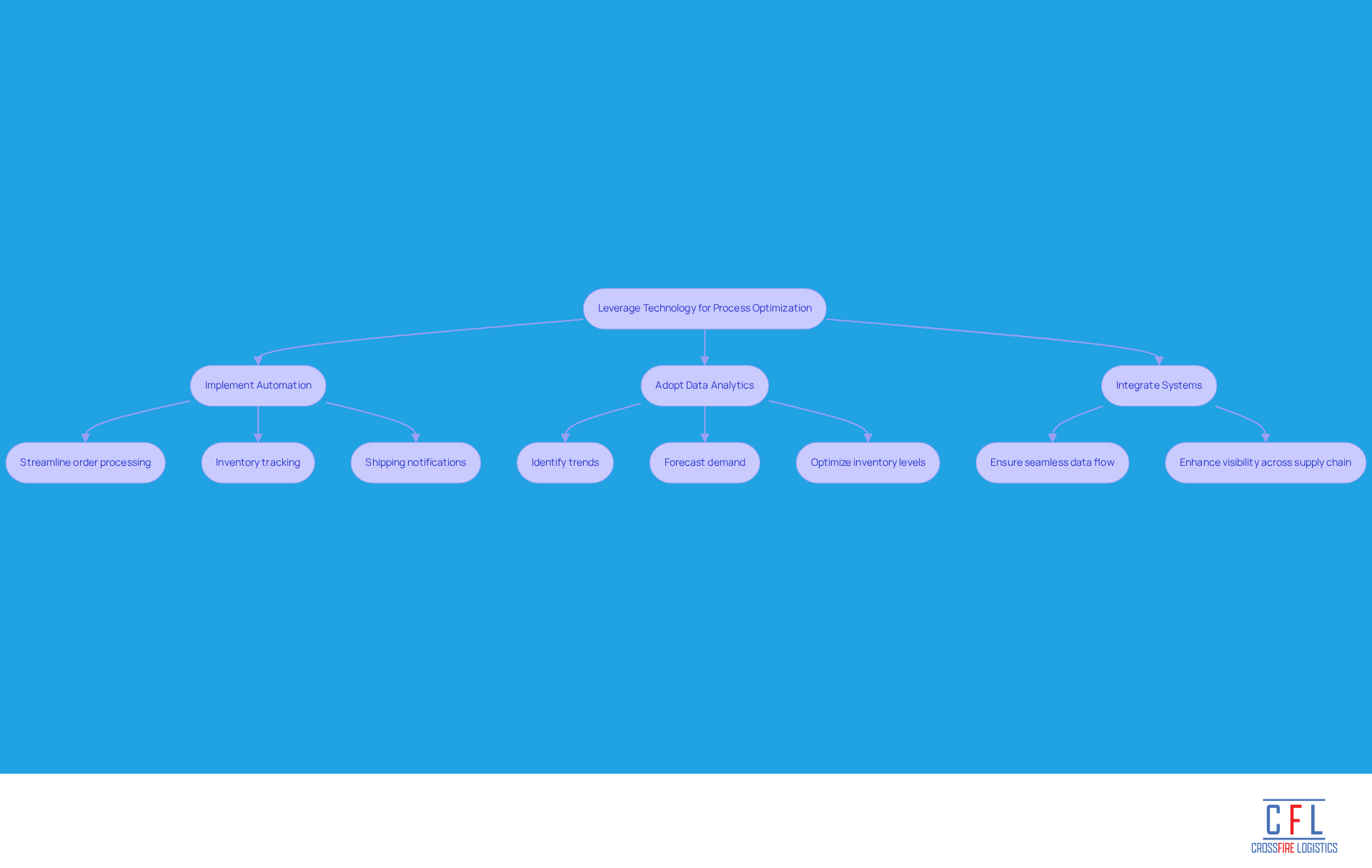

Leverage Technology for Process Optimization

Integrating technology into distribution chain management can significantly enhance efficiency and responsiveness. Here are some strategies to consider:

- Implement Automation: Automation tools can streamline repetitive tasks such as order processing, inventory tracking, and shipping notifications. This not only reduces human error but also allows staff to focus on more strategic activities.

- Adopt Data Analytics: Data analytics provides valuable insights into supply network performance, helping to identify trends and make informed decisions. Predictive analytics, in particular, can forecast demand and optimize inventory levels effectively.

- Integrate Systems: It is crucial to ensure that all supply chain systems - such as ERP, WMS, and TMS - are integrated. This integration facilitates seamless data flow and enhances visibility across the supply chain.

By leveraging these technologies, businesses can optimize their distribution chain management processes, which leads to improved operational efficiency and greater customer satisfaction.

Conclusion

Effective distribution chain management is crucial for businesses seeking to enhance operational efficiency and customer satisfaction. By grasping the complexities of the supply chain landscape, companies can formulate targeted strategies that address various components, including:

- Stakeholder communication

- Inventory management

- Technological integration

Key insights emphasize the significance of:

- Supply chain mapping

- Staying informed about market dynamics

- Ensuring regulatory compliance

Moreover, fostering open communication among stakeholders, implementing effective inventory management techniques, and leveraging technology for process optimization are essential practices that contribute to a cohesive and responsive distribution network. These strategies not only streamline operations but also empower businesses to adapt swiftly to market changes and challenges.

In summary, adopting these best practices in distribution chain management can markedly enhance operational performance and customer experiences. As businesses navigate the evolving landscape of supply chain dynamics, prioritizing these strategies is vital for maintaining a competitive edge. Organizations should evaluate their current practices and implement these recommendations to drive efficiency and resilience in their distribution chains, ultimately fostering sustained growth and success in the marketplace.

Frequently Asked Questions

What is the supply chain landscape?

The supply chain landscape refers to the network of various stakeholders involved in distribution chain management, including suppliers, manufacturers, distributors, and retailers. Understanding the flow of goods and information among these entities is crucial for optimizing logistics operations.

Why is supply chain mapping important?

Supply chain mapping is important because it provides a visual representation of the supply chain, identifying all parties involved and their roles. This process helps detect potential bottlenecks and areas for improvement, leading to enhancements in operational efficiency and responsiveness.

How do market dynamics affect supply chain management?

Market dynamics, including trends, customer demands, and competitive pressures, affect supply chain management by necessitating proactive adjustments to strategies. Staying aware of these dynamics is essential for maintaining agility and a competitive edge in a rapidly changing environment.

What role does the regulatory environment play in supply chain management?

The regulatory environment plays a significant role in supply chain management as compliance requirements can impact logistics operations. A comprehensive understanding of these regulations helps businesses mitigate risks associated with non-compliance.

How can businesses enhance their distribution chain management processes?

Businesses can enhance their distribution chain management processes by incorporating supply chain mapping, staying attuned to market dynamics, and understanding the regulatory environment into their strategic planning, ultimately resulting in improved efficiency and customer satisfaction.