Introduction

Understanding the complexities of shipping container transport services is crucial for businesses looking to excel in a competitive landscape. By mastering logistics, selecting dependable partners, leveraging technology, and implementing effective inventory management strategies, organizations can significantly boost their operational efficiency.

However, with numerous factors influencing the process, how can companies effectively navigate these challenges to ensure timely and smooth deliveries? This article explores best practices that can enhance shipping container transport services, offering insights that lead to improved service delivery and heightened customer satisfaction.

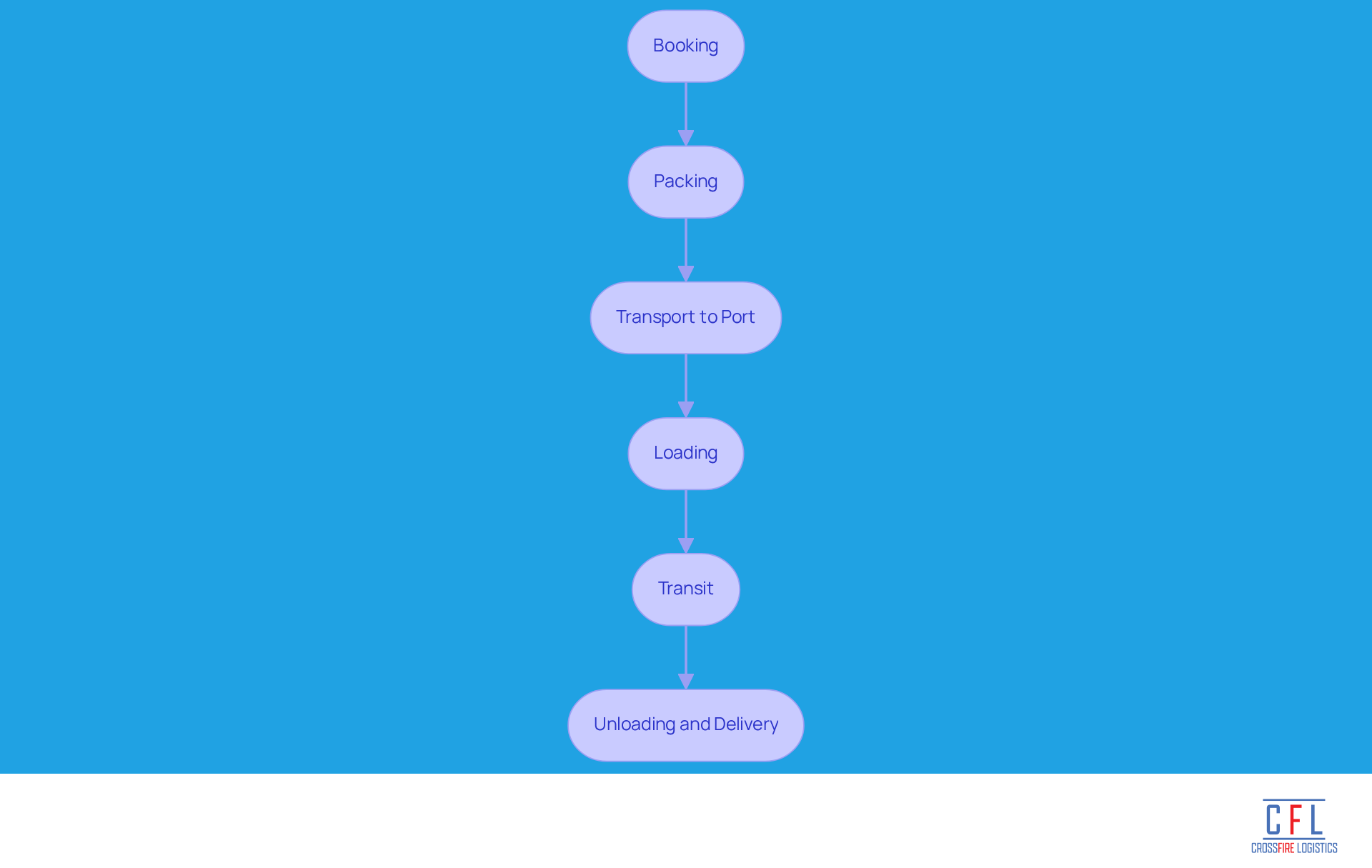

Understand the Container Shipping Process

To effectively oversee shipping container transport services, a comprehensive understanding of the entire logistics process is essential. This process encompasses several key steps:

- Booking: Secure space on a vessel through a freight forwarder or transport line, ensuring that all necessary documentation is prepared. This initial step is vital for establishing a reliable shipping schedule.

- Packing: Load items into boxes, adhering to weight limits and employing proper packing techniques to prevent damage. Effective packing not only protects cargo but also maximizes space, significantly lowering transport costs.

- Transport to Port: Arrange for the shipment to be moved to the port, considering timing to avoid delays. This step requires coordination to ensure that shipments arrive on schedule, minimizing the risk of missed sailings.

- Loading: Ensure that units are loaded onto the vessel efficiently, following safety protocols. Efficient loading practices can reduce turnaround times at the port, enhancing overall operational efficiency.

- Transit: Monitor the shipment during transit, keeping track of any potential delays or issues. Real-time visibility into the shipment's status allows for proactive management of any disruptions that may arise.

- Unloading and Delivery: Upon arrival, crates must be unloaded and conveyed to their final destination, concluding the delivery process. Timely unloading and delivery are essential for maintaining customer satisfaction and operational flow.

At Crossfire Logistics, we manage all these steps to ensure your products reach customers smoothly and efficiently. By mastering these processes, supply chain experts can streamline operations and enhance overall efficiency, ultimately leading to improved service delivery and customer satisfaction. We believe that cooperation with our partners is essential for navigating the complexities of shipping container transport services in today's unpredictable market, ensuring resilience and flexibility in our supply chain solutions.

Choose Reliable Partners for Seamless Operations

Choosing the appropriate shipping partners is crucial for ensuring smooth shipping container transport services during transportation operations. To enhance your logistics strategy, consider the following key factors:

-

Reputation: Investigate potential partners' reputations through client reviews and testimonials. A partner with a proven track record is more likely to provide reliable shipping container transport services, which are essential for maintaining operational efficiency and customer satisfaction.

-

Capabilities: Assess whether the partner can fulfill your specific transportation needs, including their ability to manage specialized cargo and provide additional services such as customs clearance and shipping container transport services. This ensures that all aspects of your supply chain requirements are met.

-

Communication: Opt for partners who prioritize open communication, offering timely updates on shipment status and proactively addressing any potential issues. Effective communication fosters alignment and helps resolve challenges swiftly, enhancing overall operational flow.

-

Technology Integration: Ensure that your partners utilize advanced technology that aligns with your systems. This integration enhances coordination and visibility, enabling real-time tracking and data analytics that can improve operational efficiency.

-

Flexibility: Seek partners who demonstrate adaptability to changing demands and can provide innovative solutions during disruptions. A versatile transportation partner can assist in managing variations in demand, ensuring that your supply chain remains robust.

By carefully selecting logistics partners based on these criteria, businesses can significantly enhance their operations, reduce risks, and improve customer satisfaction.

Utilize Technology for Enhanced Shipment Visibility

Incorporating technology into shipping container transport services significantly enhances visibility and efficiency. Key technologies include:

-

Real-Time Tracking Systems: Utilizing GPS and RFID technologies enables ongoing surveillance of shipment locations and conditions. This proactive approach allows logistics managers to address potential issues in shipping container transport services before they escalate, ensuring smoother operations. For instance, Hapag-Lloyd has introduced real-time container tracking for nearly 3 million shipping container transport services, providing customers with unmatched visibility during the transport process.

-

Data Analytics: Advanced data analytics tools can examine transport patterns and forecast potential delays. Industry statistics indicate that companies utilizing data analytics can reduce delivery delays by up to 30%. By leveraging historical data, businesses can optimize planning and resource allocation, leading to more reliable delivery schedules.

-

Automated Notifications: Implementing automated alerts for critical milestones such as departure, arrival, and customs clearance keeps all stakeholders informed. This transparency fosters better communication and coordination throughout the shipping container transport services process. As Kenney S. Christiansen, CEO of Gatehouse Maritime, emphasizes, maintaining trust-based relationships with clients is crucial, and automated notifications play a key role in achieving this.

-

Integrated Platforms: Integrated delivery platforms consolidate data from various partners, providing a single source of truth for shipment status. This holistic view enhances decision-making and reduces the risk of miscommunication. For example, the collaboration between Gatehouse Maritime and OceanIO has enhanced real-time visibility of containers and vessels, which allows for better planning and execution of shipping container transport services.

-

Mobile Applications: Mobile applications provide on-the-go access to shipment information, enabling managers to make informed decisions swiftly. This flexibility is crucial in today’s fast-paced logistics environment, where timely information can significantly impact operational efficiency.

By adopting these technologies, businesses can not only improve operational efficiency but also enhance customer satisfaction, ultimately leading to a more resilient supply chain. Addressing common pitfalls, such as integration challenges and data security concerns, is essential for successful implementation.

Implement Effective Inventory Management Strategies

Effective stock control is crucial for optimizing the efficiency of shipping container transport services. Here are key strategies to enhance your operations:

-

Just-In-Time (JIT) Stock: Implementing JIT principles can significantly reduce holding costs by 30-50% while ensuring that goods are available precisely when needed. This method minimizes waste and improves responsiveness to customer demand, aligning stock levels with real-time needs. Industry studies indicate that JIT can save up to 75% on warehouse space, making it a vital strategy for logistics efficiency.

-

ABC Analysis: Utilize ABC analysis to classify stock into three categories (A, B, C) based on their value and turnover rates. This classification enables businesses to prioritize management efforts on high-value items, ensuring that critical stock is always available while optimizing resources for less critical items. Firms with top-tier stock management practices maintain a consistent flow of raw materials and finished products, showcasing the efficiency of this approach.

-

Regular Audits: Conduct regular stock assessments to maintain accuracy and identify discrepancies. This practice is essential for avoiding stockouts and overstock situations, ultimately enhancing stock integrity and operational efficiency. Regular audits help businesses avoid common pitfalls, such as mismanagement of stock levels, which can disrupt operations.

-

Forecasting: Utilize advanced demand forecasting tools to anticipate stock requirements based on historical data and market trends. Precise forecasting allows for improved planning and ensures that stock levels match expected demand, minimizing the chance of surplus or shortages. Predictive picking software can direct businesses to initiate fulfillments before an order is placed, enhancing responsiveness.

-

Technology integration requires investing in stock management software that seamlessly integrates with shipping container transport services. This technology provides real-time updates and increases precision, facilitating efficient monitoring of stock across various locations and enhancing overall supply chain visibility. As Abby Jenkins, a Product Marketing Manager, states, "The capability to monitor stock in real-time can be a game-changer for any business."

By adopting these strategies, businesses can streamline their inventory management processes, leading to increased efficiency and enhanced customer satisfaction.

Conclusion

Understanding and optimizing shipping container transport services is crucial for businesses looking to enhance operational efficiency and customer satisfaction. Mastering the container shipping process, selecting reliable partners, leveraging technology, and implementing effective inventory management strategies are essential components of this optimization. Collectively, these best practices contribute to a smoother logistics experience, ensuring efficient transportation and timely delivery of goods.

Key points include critical steps in the shipping process:

- Booking

- Packing

- Transport to port

- Loading

- Transit

- Delivery

The importance of choosing reputable partners who prioritize communication and flexibility cannot be overstated. Advanced technologies play a significant role in improving shipment visibility and operational efficiency. Furthermore, effective inventory management strategies, such as Just-In-Time stock and regular audits, are vital for minimizing costs and maximizing responsiveness to customer demand.

By adopting these best practices, businesses can streamline their shipping container transport services and foster resilience in their supply chains. Embracing technology and maintaining strong partnerships will be essential for navigating the complexities of logistics in a constantly evolving market. Ultimately, a commitment to these practices will enhance service delivery, improve customer relationships, and create a more robust operational framework.

Frequently Asked Questions

What are the key steps in the container shipping process?

The key steps in the container shipping process include booking, packing, transport to port, loading, transit, and unloading and delivery.

What is the importance of booking in the shipping process?

Booking is vital for securing space on a vessel and establishing a reliable shipping schedule, ensuring that all necessary documentation is prepared.

How should items be packed for shipping?

Items should be loaded into boxes while adhering to weight limits and employing proper packing techniques to prevent damage and maximize space, which can lower transport costs.

What considerations should be made when transporting items to the port?

It is important to arrange for the shipment to be moved to the port in a timely manner to avoid delays and ensure that shipments arrive on schedule.

What is involved in the loading step of the shipping process?

The loading step involves ensuring that units are loaded onto the vessel efficiently and following safety protocols to reduce turnaround times at the port.

How can one monitor shipments during transit?

Monitoring shipments during transit involves keeping track of any potential delays or issues, allowing for proactive management of disruptions through real-time visibility.

What happens during the unloading and delivery stage?

Upon arrival, crates must be unloaded and conveyed to their final destination, with timely unloading and delivery being essential for maintaining customer satisfaction and operational flow.

How does Crossfire Logistics assist in the container shipping process?

Crossfire Logistics manages all steps of the shipping process to ensure products reach customers smoothly and efficiently, enhancing overall service delivery and customer satisfaction.