Introduction

Efficient inventory management is a cornerstone of successful logistics operations. It directly influences both cost control and customer satisfaction. By mastering stock oversight, businesses can streamline their supply chains, ensuring that the right products are available precisely when needed.

However, common challenges such as demand forecasting errors and manual process inefficiencies can hinder this optimization. How can organizations truly enhance their inventory practices to thrive in a competitive marketplace?

Understand the Importance of Inventory Management in Logistics

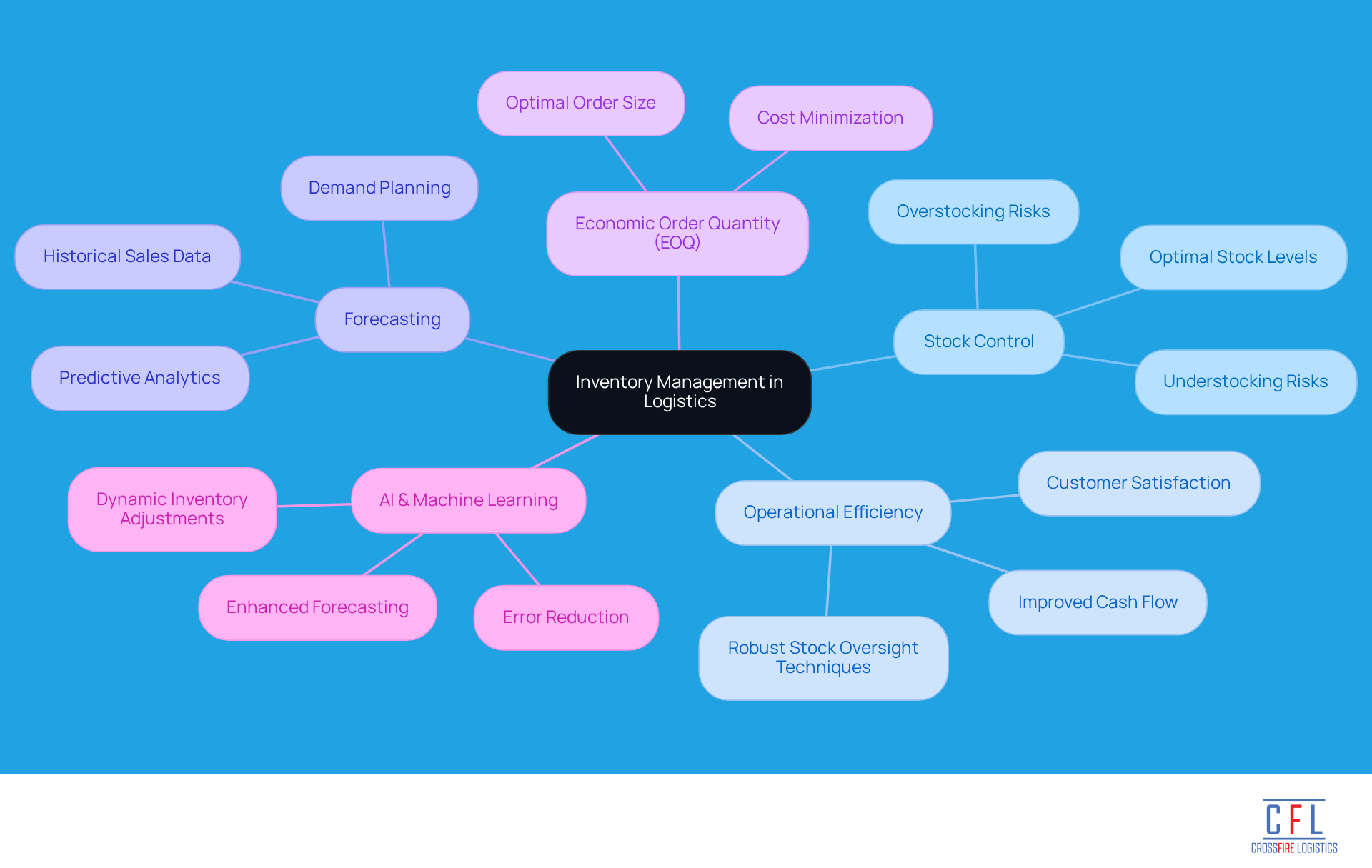

Efficient stock control is essential in understanding how to improve inventory management logistics. It ensures that the right products are available at the right time, which minimizes delays and reduces costs. By maintaining optimal stock levels, businesses can discover how to improve inventory management logistics to meet customer demand effectively without the risks of overstocking or understocking.

Implementing robust stock oversight techniques is a key strategy for how to improve inventory management logistics, as it can significantly enhance operational efficiency, improve cash flow, and ultimately boost customer satisfaction. Moreover, accurate stock monitoring facilitates better forecasting and planning-crucial elements in today’s fast-paced market environment. Understanding these principles is essential for learning how to improve inventory management logistics and optimizing logistics operations.

Effective inventory oversight is essential in understanding how to improve inventory management logistics to ensure that supply flows at the speed of global commerce. Utilizing strategies like Economic Order Quantity (EOQ) can help businesses determine the most economical order size, leading to cost savings.

Additionally, advancements in AI and machine learning are set to provide insights on how to improve inventory management logistics and reduce errors. It is vital for logistics coordinators to adapt to these developments. Inefficient stock oversight can adversely affect the bottom line, underscoring the need for effective practices within the supply chain.

Identify Common Inventory Management Challenges

Common stock control challenges primarily stem from flawed demand forecasting, which can lead to stockouts or surplus goods. Limited visibility into stock levels often results in ineffective supply management, causing delays in order fulfillment. Additionally, manual processes frequently introduce errors in monitoring and reporting, complicating stock management further.

Other significant challenges include:

- Managing seasonal demand fluctuations

- Integrating stock control systems with broader logistics operations

By identifying these challenges, companies can implement targeted strategies that demonstrate how to improve inventory management logistics.

Implement Effective Inventory Management Techniques

To improve stock management, consider implementing the following techniques:

-

Just-In-Time (JIT) Stock: This approach minimizes stock levels by ordering goods only as required, significantly reducing holding costs and enhancing cash flow. JIT aligns stock delivery with production schedules, ensuring materials arrive precisely when needed, thus promoting operational efficiency. Companies that adopt JIT can reduce storage costs and minimize waste, as evidenced by various case studies.

-

ABC Analysis: This method classifies stock into three categories (A, B, and C) according to their significance and worth. Class A items, which constitute approximately 80% of asset value but only about 20% of item counts, require concentrated oversight to utilize resources efficiently. Regularly reviewing these categories can enhance inventory oversight and lower holding expenses. Expert insights, such as those from Abby Jenkins, underscore the importance of prioritizing high-value items in stock control.

-

Automated Inventory Systems: Leveraging technology to automate tracking and reporting enhances accuracy and minimizes manual errors. Cloud-based systems provide real-time updates, enabling companies to monitor supply levels from any device, which is essential for maintaining optimal resource quantities. Recent advancements in AI and machine learning further streamline these processes, making stock control more efficient.

-

Demand Forecasting: Utilizing historical data and market trends to predict future demand enables better planning and stock management. This proactive strategy helps prevent surplus stock and shortages, ensuring that companies can effectively meet customer needs.

By applying these techniques, organizations can learn how to improve inventory management logistics, thereby significantly enhancing their stock efficiency and overall supply chain performance.

Adopt Best Practices for Inventory Management

To ensure effective inventory management, businesses should adopt several best practices:

-

Regular Audits: Periodic stock checks are essential for maintaining accuracy and identifying discrepancies. Regular audits improve operational efficiency and provide valuable insights for better stock management and decision-making. For instance, companies like KiwiCo have enhanced their delivery speed and reduced expenses by implementing organized audit processes. This demonstrates the tangible benefits of routine stock assessments. In fact, effective stock management practices can lead to an 80% reduction in manual stock effort.

-

Establish Reorder Points: Setting minimum supply levels for each item is crucial for initiating reordering. This proactive strategy prevents shortages and ensures that quantities align with demand. By maintaining optimal stock levels, companies can minimize the risk of lost sales due to inadequate supplies.

-

Employ Technology: Implementing stock control software that integrates with other systems allows for real-time monitoring and reporting. This technology reduces human errors and enhances data accuracy, which is vital for efficient stock control. The global stock control software market is projected to grow significantly, reaching an estimated value of $4.8 billion by 2029, highlighting the increasing reliance on technology to improve operations.

-

Train Staff: It is fundamental to ensure that all employees involved in stock management are well-trained in best practices and technology usage. Comprehensive training programs can mitigate risks associated with stock audits and enhance overall efficiency.

-

Collaborate with Suppliers: Open communication with suppliers is essential for improving lead times and restocking strategies. By fostering strong relationships, businesses can enhance their supply chain resilience and responsiveness to market changes.

-

Address Seasonal Variations: Businesses should consider the impact of seasonal changes on stock levels, necessitating adaptive audit schedules to maintain stock accuracy throughout the year.

By following these best practices, companies can learn how to improve inventory management logistics, leading to greater operational efficiency and improved customer satisfaction.

Conclusion

Effective inventory management stands as a cornerstone of successful logistics operations. By prioritizing efficient stock control, businesses can ensure product availability when needed, enhancing customer satisfaction while minimizing costs. The significance of mastering inventory management strategies cannot be overstated; it plays a crucial role in optimizing logistics performance and maintaining a competitive edge in the market.

Key insights discussed throughout the article highlight the importance of addressing common inventory management challenges, such as:

- Flawed demand forecasting

- Limited visibility into stock levels

Techniques like Just-In-Time stock, ABC analysis, and automated inventory systems have proven effective in improving efficiency and accuracy. Additionally, adopting best practices such as:

- Regular audits

- Establishing reorder points

- Leveraging technology

are vital steps for organizations aiming to enhance their inventory oversight and streamline operations.

In summary, the journey toward improved inventory management in logistics is not solely about implementing new techniques; it requires a holistic approach that encompasses technology, training, and collaboration. By embracing these strategies, companies can not only overcome existing challenges but also position themselves for future success in an ever-evolving marketplace. The time to act is now; adopting these practices can lead to significant improvements in operational efficiency and customer satisfaction, ultimately driving business growth.

Frequently Asked Questions

Why is inventory management important in logistics?

Inventory management is crucial in logistics because it ensures that the right products are available at the right time, minimizing delays and reducing costs.

How can businesses improve their inventory management logistics?

Businesses can improve inventory management logistics by maintaining optimal stock levels, implementing robust stock oversight techniques, and utilizing strategies like Economic Order Quantity (EOQ) to determine the most economical order size.

What are the benefits of effective stock oversight?

Effective stock oversight enhances operational efficiency, improves cash flow, and boosts customer satisfaction. It also facilitates better forecasting and planning.

How does accurate stock monitoring impact logistics operations?

Accurate stock monitoring allows for better forecasting and planning, which are essential in today’s fast-paced market environment, thereby optimizing logistics operations.

What role do advancements in AI and machine learning play in inventory management?

Advancements in AI and machine learning provide insights that can improve inventory management logistics and reduce errors, helping logistics coordinators to adapt to new developments.

What are the risks of inefficient stock oversight?

Inefficient stock oversight can adversely affect a business's bottom line, leading to issues such as overstocking or understocking, which can disrupt supply flow.