Introduction

Automated inventory control is transforming the logistics landscape. It provides businesses with a powerful tool to enhance efficiency and accuracy in stock management. By leveraging advanced technologies like RFID and barcode scanning, companies can gain real-time visibility into their inventory. This capability drastically reduces errors and improves response times to market demands.

However, transitioning to automated systems presents challenges. Organizations must consider how to effectively implement these technologies while ensuring their teams are prepared to adapt. This guide outlines six essential steps to master automated inventory control, empowering logistics professionals to navigate this critical shift with confidence.

- Assess current inventory processes

- Identify suitable technologies

- Train staff on new systems

- Integrate automated solutions with existing workflows

- Monitor performance and make adjustments

- Continuously evaluate and improve inventory management practices

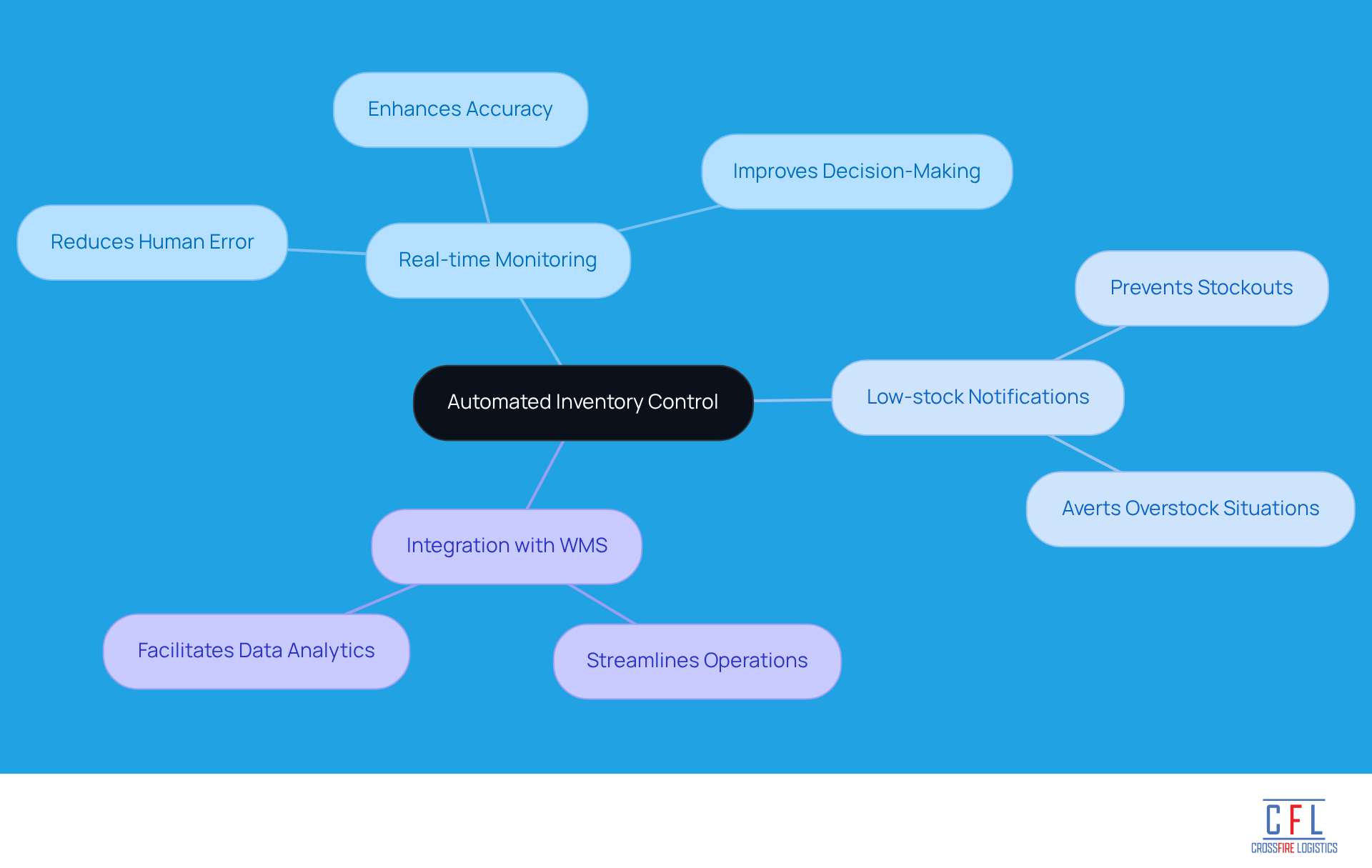

Understand Automated Inventory Control

Automated inventory control utilizes advanced technology to oversee and monitor stock levels with minimal manual intervention. By employing software and hardware tools such as barcode scanners and RFID tags, this system enables real-time tracking of stock, significantly reducing human error and enhancing accuracy. For instance, a global logistics firm reported a 200% increase in picking efficiency and a 50% reduction in cycle duration after implementing Autonomous Mobile Robots (AMRs) for stock management (Global Logistics Company). This shift highlights the essential role of automation in streamlining operations and boosting overall efficiency.

Key features of stock management systems include:

- Real-time monitoring

- Low-stock notifications

- Integration with Warehouse Management Systems (WMS)

These functionalities not only support proactive stock management-helping to avert stockouts and overstock situations-but also improve decision-making through data analytics. As the warehousing sector continues to evolve, the adoption of such technologies is expected to rise significantly, with projections indicating that by 2025, over 4 million warehouse robots will be operational globally (Team Omniful).

The impact of automated inventory control on the efficiency of the supply chain is substantial. By optimizing stock turnover rates and maintaining accurate stock levels, businesses can respond quickly to market demands, thereby enhancing customer satisfaction. Industry insights emphasize that maintaining stock accuracy above 95% is vital for preventing stockouts and excess inventory, which can strain cash flow (stats).

As industry experts note, 'Warehouse automation ROI is key for businesses considering new technology' (Team Omniful). This perspective underscores the increasing acknowledgment of automation as not merely a trend, but a necessity for contemporary logistics operations. By embracing automated inventory control, companies can strategically position themselves for success in a competitive landscape.

Identify Benefits of Automated Inventory Control

Automated inventory control offers a range of significant advantages that can fundamentally enhance logistics operations. The key benefits include:

- Increased Accuracy: Automated systems significantly minimize human errors in inventory tracking, achieving accuracy rates exceeding 99% in optimized implementations. This level of precision ensures reliable stock levels, which helps to avoid costly stockouts and overstocks that can disrupt operations. Notably, 39% of small enterprises in the U.S. still rely on manual stock monitoring or do not track inventory at all, highlighting the urgent need for automation.

- Time Savings: By automating routine tasks such as stock assessments and data entry, businesses can free up valuable time for their staff. This transition allows employees to focus on strategic initiatives, thereby enhancing overall productivity. Companies that implement automation report average annual benefits of $750,000 against an implementation investment of approximately $275,000, illustrating the financial advantages of this shift. Additionally, 76% of businesses utilize automation to standardize or automate daily workflows, further supporting time savings.

- Real-Time Visibility: Automation provides immediate insights into stock levels, enabling businesses to respond swiftly to changes in demand. This capability is crucial in today’s fast-paced market, where 67% of companies plan to adopt real-time stock management solutions by 2025 to enhance precision and meet consumer demands.

- Cost Reduction: Optimizing stock levels through computerized methods can lead to significant reductions in carrying costs. Studies indicate that effective stock oversight can lower overall stock costs by up to 12%. This improvement directly influences cash flow, allowing companies to allocate resources more efficiently. Furthermore, 51% of IT leaders believe that automation initiatives can reduce overall costs by 10% to 50%, reinforcing the claims of cost reduction.

- Improved Customer Contentment: Accurate stock oversight ensures that products are available when customers need them, which is vital for maintaining high service standards. Companies that adopt automated inventory control systems report a 30% increase in order fulfillment rates, which directly correlates with improved customer retention and satisfaction. Additionally, 35% of companies have experienced delays in order dispatch due to stockouts, underscoring the importance of precise stock management. By preventing stockouts, businesses can avoid the $1 trillion in missed sales associated with stock level discrepancies worldwide.

Integrating systematic stock management not only streamlines operations but also positions businesses for success in a competitive landscape, ultimately enhancing customer experiences and boosting profitability.

Select Appropriate Technology for Implementation

Choosing the appropriate technology for automated inventory control is essential for optimizing business operations. Here are the essential steps to guide your decision-making process:

- Evaluate Your Requirements: Identify the specific needs of your business, including stock volume, product categories, and compatibility with existing systems.

- Research Available Solutions: Investigate various stock control software options, focusing on features such as real-time tracking, reporting capabilities, and user-friendliness.

- Evaluate Integration Capabilities: Confirm that the chosen technology can integrate seamlessly with your current logistics and warehouse management platforms.

- Consider Scalability: Opt for a solution that can grow alongside your business, accommodating increased stock levels and additional functionalities as necessary.

- Seek Vendor Support: Choose vendors that provide strong customer support and training resources to facilitate implementation and ongoing usage.

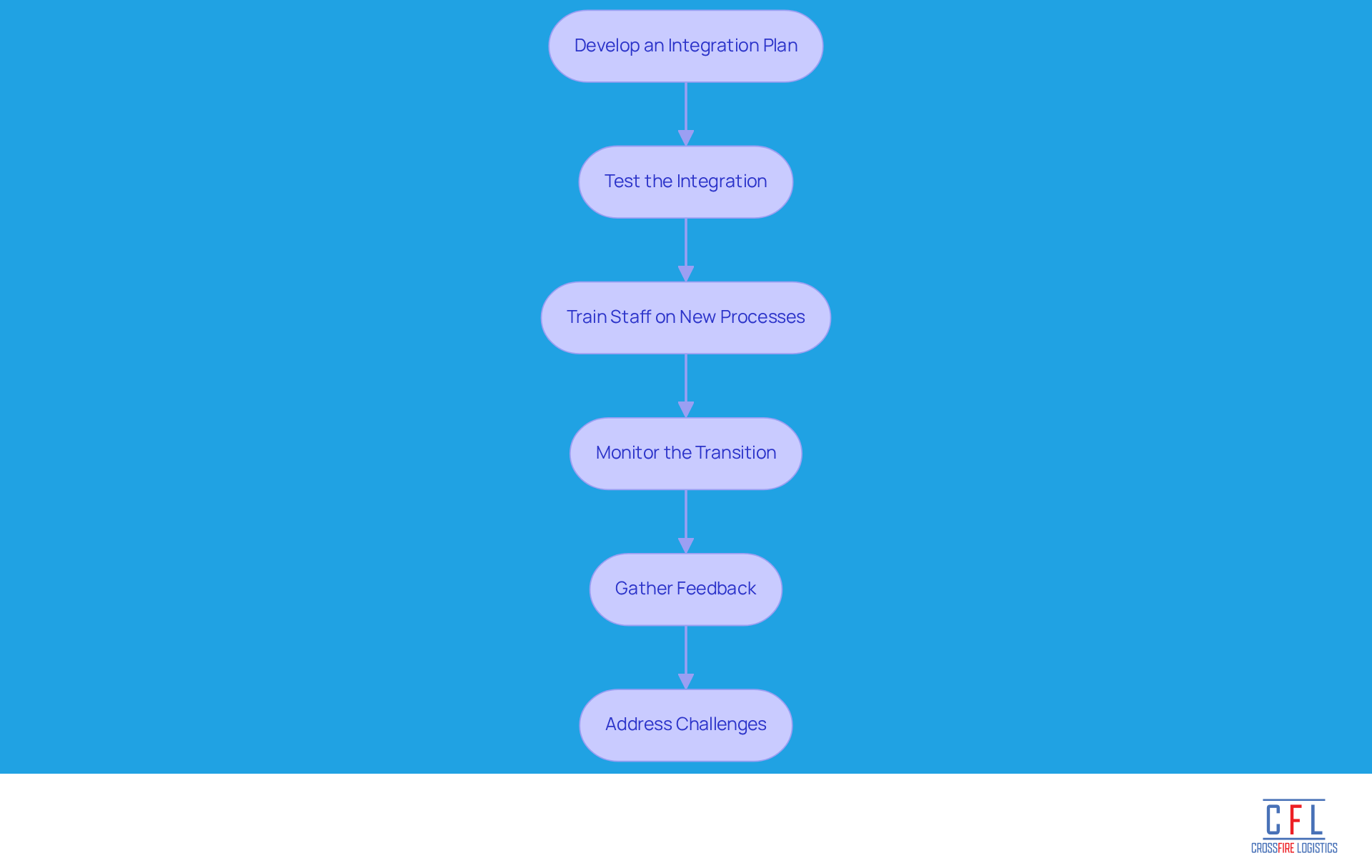

Integrate Automated Systems with Existing Operations

Incorporating automated inventory control into current operations requires careful planning and execution to ensure a seamless transition. Here are key steps to consider:

-

Develop an Integration Plan: Create a comprehensive outline detailing the necessary steps to link the new framework with existing processes. This plan should include specific timelines, responsibilities, and resource allocation to facilitate a smooth integration.

-

Test the Integration: Before full execution, conduct thorough testing to confirm that data transfers accurately between networks and that all features function as expected. This step is crucial for identifying potential issues early on.

-

Train Staff on New Processes: Equip employees with the knowledge and skills needed to effectively utilize the new framework. Training should emphasize how the automated inventory system impacts their roles and responsibilities, fostering a culture of adaptability.

-

Monitor the Transition: During the initial integration phase, closely observe operations to quickly identify and resolve any challenges that may arise. Ongoing monitoring ensures that the framework operates as anticipated and meets operational requirements.

-

Gather Feedback: Actively solicit input from staff regarding their experiences with the new platform. This feedback is invaluable for refining processes and enhancing user experience, ultimately leading to improved operational efficiency.

-

Address Challenges: Be prepared to tackle common integration challenges, such as data compatibility issues and resistance to change among staff. Developing a proactive strategy to address these obstacles can significantly enhance the success of the integration process.

By following these steps, organizations can effectively incorporate automated inventory control solutions, resulting in enhanced accuracy and productivity in stock management. Statistics indicate that companies employing automated processes experience a notable increase in stock accuracy, with some reporting levels as high as 97%. This level of precision not only streamlines operations but also strengthens overall supply chain resilience.

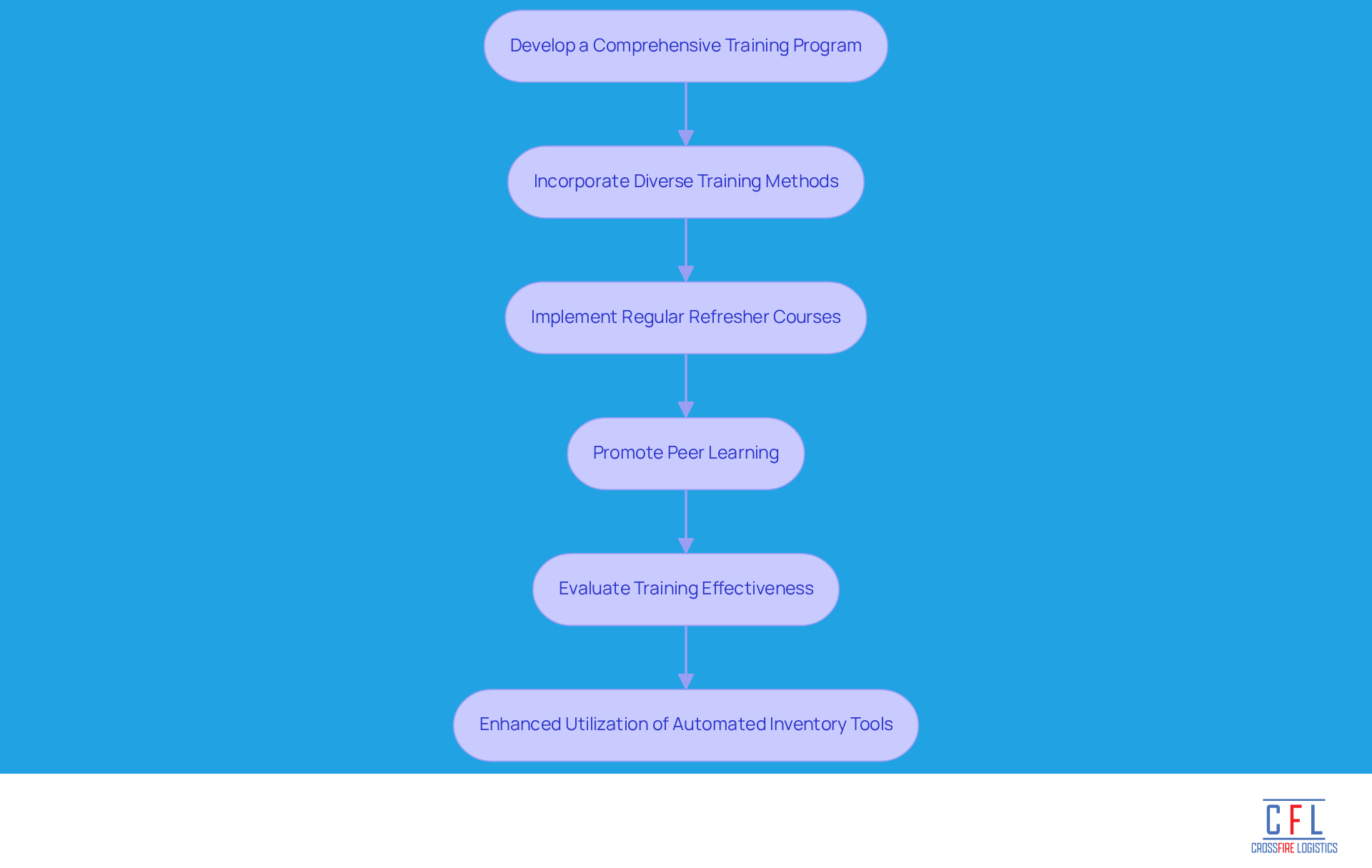

Train Staff for Effective System Utilization

Training personnel to effectively utilize automated inventory control tools is essential for optimizing logistics operations. To ensure successful implementation, consider the following key steps:

-

Develop a Comprehensive Training Program: Create a detailed curriculum that covers operational functionalities, best practices, and troubleshooting techniques. This equips staff with the necessary skills to navigate the tools effectively.

-

Incorporate Diverse Training Methods: Utilize a blend of training approaches, including hands-on sessions, online courses, and instructional videos. This accommodates various learning preferences and enhances engagement among staff.

-

Implement Regular Refresher Courses: Arrange continuous training sessions to keep staff updated on upgrades and new features. This ensures they remain proficient in utilizing the technology.

-

Promote Peer Learning: Encourage experienced users to mentor newer staff. This fosters a collaborative environment that enhances overall team competency and knowledge sharing.

-

Evaluate Training Effectiveness: Continuously assess the impact of training programs through feedback and performance metrics. This allows for necessary adjustments to improve outcomes.

By emphasizing these strategies, logistics companies can ensure their teams are well-prepared to utilize automated inventory control for efficient stock management. This ultimately enhances efficiency and precision in operations. According to industry insights, 54% of organizations plan to invest in supply chain and technical training to retain their workforce. This highlights the critical role of effective training in today’s logistics landscape. Additionally, with the warehouse control system market anticipated to reach approximately $10.5 billion by 2030, the significance of training personnel on these evolving technologies cannot be overstated.

Monitor and Optimize Inventory Control Processes

To ensure the ongoing success of automated inventory control processes, consider implementing the following strategies:

-

Establish Key Performance Indicators (KPIs): Define specific KPIs to assess the effectiveness of stock control. Key metrics include turnover rates, indicating how often stock is sold and replaced, and order accuracy, reflecting the precision of order fulfillment. A high turnover rate suggests efficient management, while precise orders enhance customer satisfaction. As noted, "Accuracy: No more guesswork. Real-time data ensures you know exactly what’s in stock and where it’s located."

-

Utilize Analytics Tools: Leverage advanced analytics tools to gain insights into stock trends and performance. These tools assist in recognizing slow-moving stock, optimizing reorder points, and forecasting demand more precisely. This ultimately results in enhanced stock management efficiency and lower carrying expenses. Radio Frequency Identification (RFID) is one of the most impactful tools in modern warehousing, enhancing real-time tracking capabilities.

-

Conduct Regular Audits: Arrange routine evaluations to confirm stock levels and assess the precision of the automated process. Regular inspections help spot inconsistencies, such as stock reduction, ensuring that the setup accurately reflects true stock amounts. This is essential for upholding operational integrity.

-

Adjust Processes as Needed: Be prepared to modify inventory management processes based on performance data and changing business conditions. Flexibility in operations allows for quick responses to market fluctuations, enhancing overall efficiency.

-

Solicit Feedback from Staff: Regularly gather input from employees on the platform's performance and usability. Involving personnel in the assessment process can reveal perspectives that promote ongoing enhancement, ensuring that the system meets the practical requirements of daily operations.

By implementing these strategies, logistics coordinators can enhance their automated inventory control processes, leading to improved efficiency, reduced costs, and better customer satisfaction. As emphasized, "Customer Satisfaction: With accurate stock data, 3PLs can fulfill orders quicker and prevent delays, ensuring clients are satisfied." Additionally, effective inventory management practices can lead to significant cost savings: "Cost Savings: Fewer stockouts, less overstock, and minimized waste translate to lower operational costs.

Conclusion

Mastering automated inventory control is essential for logistics companies that seek to improve operational efficiency and customer satisfaction. By utilizing advanced technologies, businesses can streamline their inventory processes, minimize errors, and ultimately position themselves for success in a competitive market.

This article presents a structured approach to implementing automated inventory control. It highlights the importance of:

- Understanding the technology

- Recognizing its benefits

- Selecting appropriate tools

- Integrating systems

- Training staff

- Continuously monitoring performance

Each step offers practical insights that can lead to significant improvements in accuracy, time savings, cost reductions, and customer satisfaction.

In the fast-paced logistics landscape, adopting automated inventory control is not just an option; it is a necessity. Companies that implement these systems can anticipate enhanced efficiency and responsiveness to market demands. The message is clear: invest in automated inventory solutions and training to ensure operations are not only efficient but also adaptable to the future of logistics. Embracing this transformation will result in improved profitability and a stronger competitive edge in the industry.

Frequently Asked Questions

What is automated inventory control?

Automated inventory control is a system that utilizes advanced technology to oversee and monitor stock levels with minimal manual intervention, employing tools such as barcode scanners and RFID tags for real-time tracking.

How does automated inventory control improve efficiency?

By reducing human error and enhancing accuracy, automated inventory control can significantly streamline operations. For example, a logistics firm reported a 200% increase in picking efficiency and a 50% reduction in cycle duration after implementing Autonomous Mobile Robots (AMRs) for stock management.

What are the key features of automated inventory control systems?

Key features include real-time monitoring, low-stock notifications, and integration with Warehouse Management Systems (WMS), which help in proactive stock management and improve decision-making through data analytics.

What benefits does automated inventory control provide?

Benefits include increased accuracy (over 99% in optimized implementations), time savings from automating routine tasks, real-time visibility into stock levels, cost reduction in carrying costs, and improved customer satisfaction through better order fulfillment rates.

How does automated inventory control impact customer satisfaction?

Accurate stock oversight ensures product availability, leading to a 30% increase in order fulfillment rates and improved customer retention. It helps prevent stockouts, which can result in significant missed sales.

What are the financial implications of implementing automated inventory control?

Companies that adopt automation report average annual benefits of $750,000 against an implementation investment of about $275,000, highlighting a strong return on investment (ROI). Additionally, effective stock oversight can lower overall stock costs by up to 12%.

What is the future outlook for automated inventory control in warehousing?

The adoption of automated inventory control technologies is expected to rise significantly, with projections indicating that over 4 million warehouse robots will be operational globally by 2025.

Why is maintaining stock accuracy important?

Maintaining stock accuracy above 95% is vital to prevent stockouts and excess inventory, which can strain cash flow and disrupt operations.