Introduction

Automated Guided Vehicles (AGVs) are transforming warehouse operations, showcasing a future where efficiency and safety are paramount. As the demand for streamlined logistics increases, it is crucial for businesses to understand the different types of AGVs and their capabilities to optimize storage facilities.

Despite the clear benefits of AGVs, many organizations face challenges in integrating this technology into their existing workflows. To ensure a smooth transition, businesses must identify key steps and strategies.

By leveraging AGVs, companies can enhance productivity while effectively addressing the complexities of modern logistics.

Understand Automated Guided Vehicles (AGVs)

Automated Guided Vehicles (AGVs) are self-operating mobile robots designed to transport materials within storage facilities without human intervention. They navigate predefined paths using advanced technologies such as laser guidance, magnetic tape, and vision systems. Understanding the various types of automated guided vehicle warehouse technologies is crucial for optimizing warehouse operations.

-

Unit Load Automated Guided Vehicles: These vehicles transport individual unit loads, such as pallets or containers, making them ideal for high-volume environments. They typically have a load capacity ranging from 1,000 to 3,000 pounds and can operate at speeds of up to 4 mph.

-

Fork Mobile Robots: Mimicking traditional forklifts, these machines autonomously lift and place loads. They are particularly beneficial in environments where vertical space is limited, with capabilities to handle loads up to 5,000 pounds.

-

Towing Vehicles: Also known as tuggers, these machines autonomously pull carts or trailers, effectively transporting multiple smaller loads across longer distances within a facility.

The market for automated guided vehicle warehouses is projected to grow significantly, with expectations of reaching $3.3 billion by 2028. This growth is driven by the increasing demand for automation in logistics, particularly in the context of automated guided vehicle warehouse solutions, in response to labor shortages and the need for enhanced operational performance. A study by Cyngn indicates that workflows in an automated guided vehicle warehouse are executed four times more efficiently than by human workers, underscoring their effectiveness in warehouse operations.

Real-world applications of AGVs span various sectors. In manufacturing, AGVs facilitate the transport of raw materials to production lines, ensuring a consistent supply. In distribution centers, the automated guided vehicle warehouse streamlines the movement of finished goods from production areas to shipping docks, significantly reducing handling times and improving accuracy. Additionally, AGVs enhance safety in hazardous environments through advanced sensors and safety mechanisms, thereby minimizing the risk of workplace accidents.

In summary, the types of AGVs - unit load, fork, and towing - each offer distinct capabilities tailored to specific storage needs. The automated guided vehicle warehouse enhances productivity, reduces labor costs, and improves safety, making it an essential component of modern logistics operations.

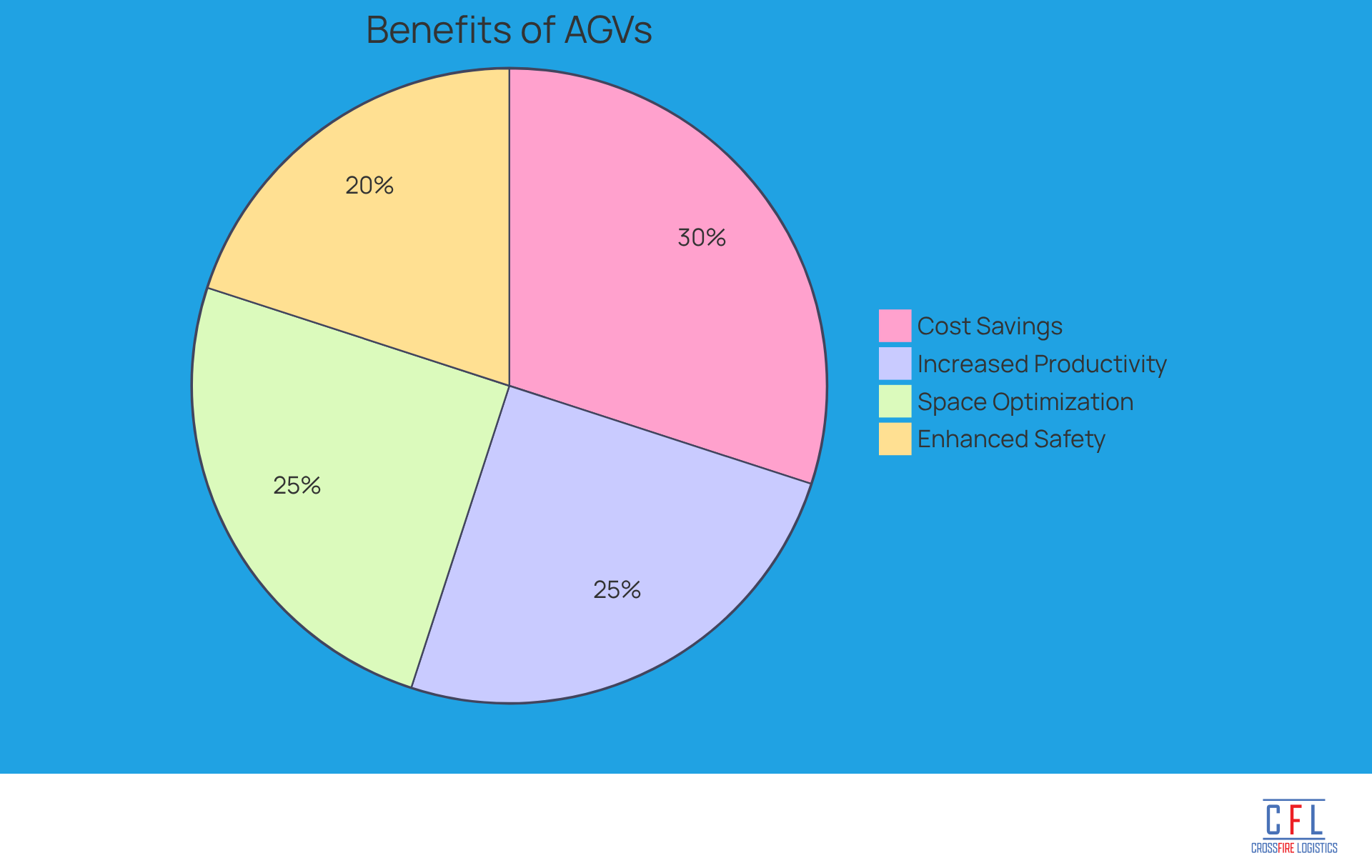

Evaluate the Benefits of AGVs in Warehouse Operations

Implementing an automated guided vehicle warehouse can lead to significant improvements in storage facility efficiency. The key benefits include:

- Increased Productivity: AGVs operate continuously without breaks, which significantly reduces downtime associated with manual labor. This capability allows warehouses to achieve a productivity increase of up to 25%, enabling faster order fulfillment and improved service levels.

- Cost Savings: By automating repetitive tasks, AGVs can lower labor costs by up to 60% and reduce operational expenses by minimizing errors. Facilities employing AGVs have reported operational cost reductions of approximately 30%, making them a financially sound investment. According to Modern Materials Handling, the implementation of an automated guided vehicle warehouse can decrease labor expenses by as much as 60%, highlighting the economic advantages of AGVs.

- Enhanced Safety: AGVs are equipped with advanced safety sensors and systems that prevent collisions, thereby reducing workplace accidents. With storage facilities facing a high injury rate, the introduction of AGVs can lead to a notable reduction in incidents, fostering a safer working environment.

- Space Optimization: AGVs can maneuver through narrow aisles and enhance storage configurations, maximizing space usage. This capability is crucial for better inventory management and can lead to a 20% gain in space utilization.

Moreover, with 73% of storage facility operators struggling to attract enough qualified labor, the necessity of automation solutions such as AGVs becomes even more evident. The global automated guided vehicle warehouse market is projected to reach $54.53 billion by 2029, reflecting the growing trend towards automation in logistics. Notably, Amazon's utilization of over 200,000 robots has led to a 30% decrease in order processing times, demonstrating the effectiveness of AGVs in improving operational efficiency.

Understanding these advantages will enable you to effectively convey the importance of AGVs to your team and stakeholders, aligning with the growing trend of automation in logistics.

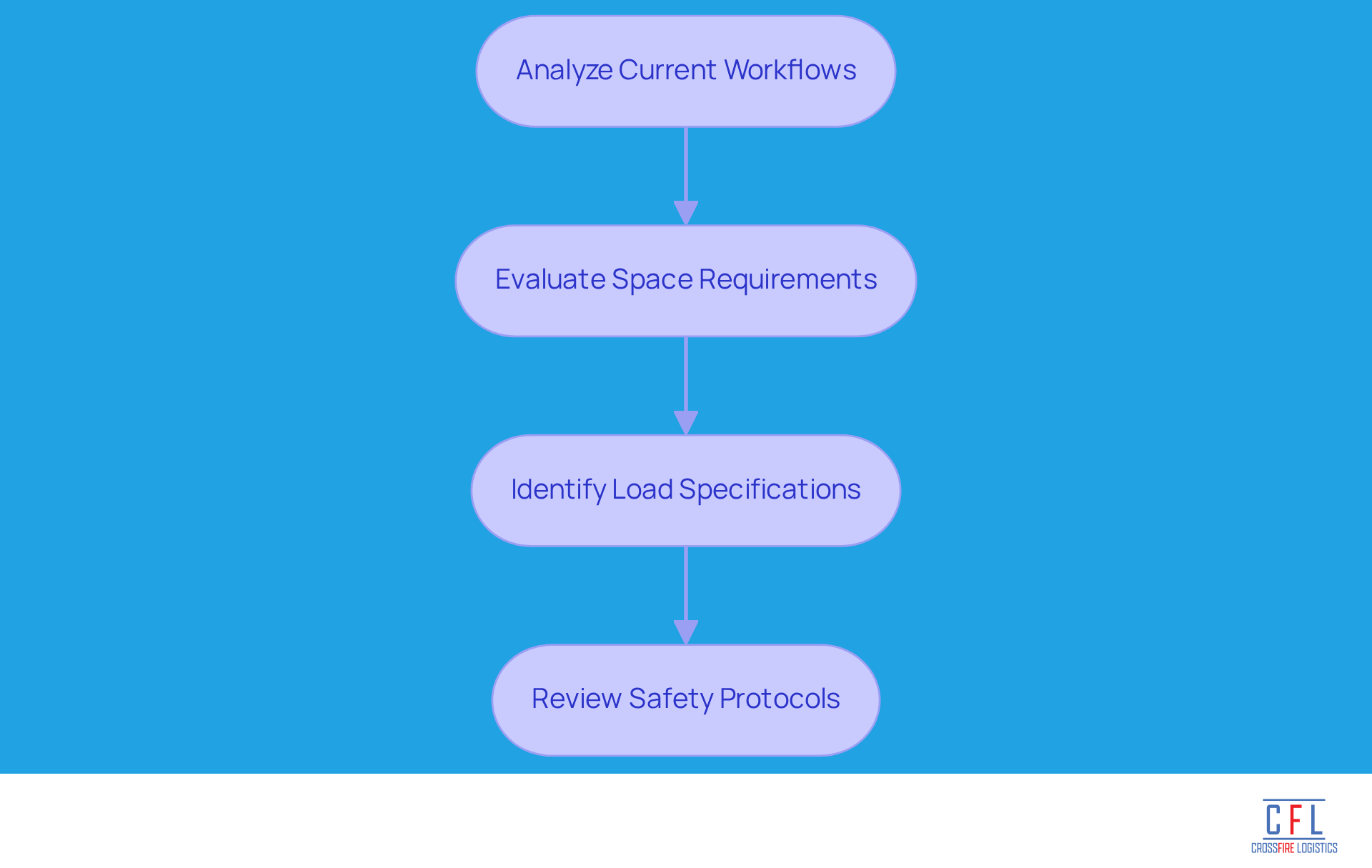

Assess Your Warehouse Needs for AGV Integration

To effectively implement an automated guided vehicle warehouse, a thorough evaluation of your existing workflows is essential. Here are the key steps to consider:

-

Analyze Current Workflows: Start by identifying repetitive tasks that are suitable for automation, such as material transport and order picking. Currently, 10% of storage facilities utilize an automated guided vehicle warehouse, and projections indicate that over 4 million robotic systems will be operational worldwide by 2025. This trend underscores the growing shift towards automation in logistics, especially with the implementation of automated guided vehicle warehouses.

-

Evaluate Space Requirements: Assess your warehouse layout to determine if it can accommodate AGVs. Pay close attention to aisle widths and storage configurations. Effective space planning is critical, particularly as 60% of companies are expected to increase their automation budgets, which highlights the necessity for efficient space utilization in an automated guided vehicle warehouse.

-

Identify Load Specifications: Determine the types of loads that AGVs will handle, including weight, dimensions, and handling requirements. Understanding these specifications is crucial, as successful integration of AGVs can lead to a 25% reduction in workplace injuries and a 35% boost in productivity.

-

Review Safety Protocols: Ensure that your existing safety measures can be adapted to include AGVs, focusing on worker interactions and emergency procedures. Safety remains a primary concern for 84% of organizations, making it vital to incorporate AGVs without compromising workplace safety.

Conducting this evaluation will provide valuable insights into how an automated guided vehicle warehouse can enhance your warehouse operations, leading to increased productivity and reduced operational costs.

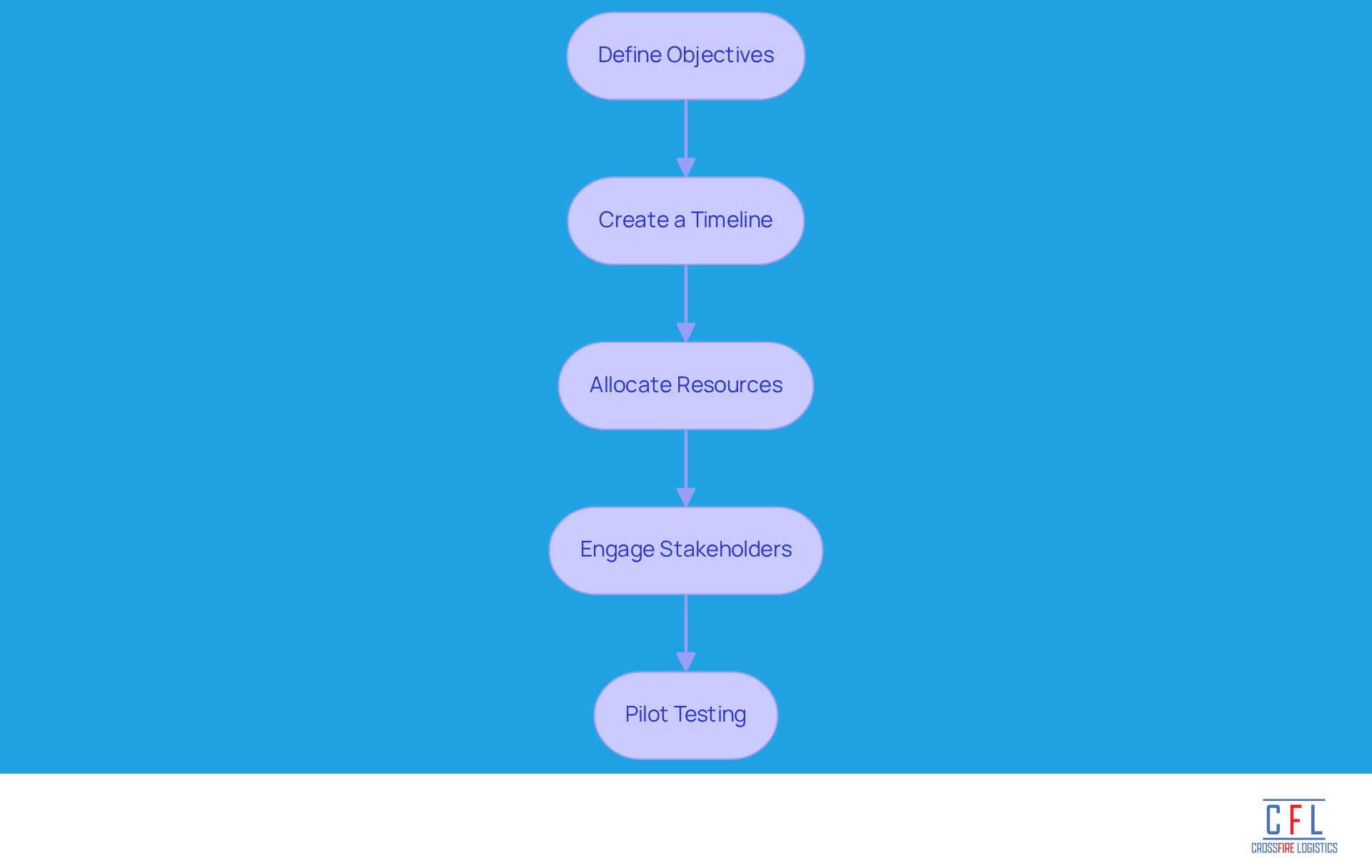

Plan Your AGV Implementation Strategy

Developing a robust implementation strategy for Automated Guided Vehicle (AGV) integration involves several key components:

-

Define Objectives: Clearly outline your goals for AGV integration, such as increasing efficiency or reducing labor costs.

-

Create a Timeline: Establish a realistic timeline for each phase of the implementation, from initial assessment to full operation.

-

Allocate Resources: Identify the necessary resources, including budget, personnel, and technology, to support the implementation.

-

Engage Stakeholders: Involve key stakeholders early in the planning process to ensure their support and address any concerns.

-

Pilot Testing: Consider running a pilot program with a limited number of automated guided vehicle warehouse systems to test their effectiveness before full-scale deployment.

This strategic planning lays the foundation for successful AGV integration.

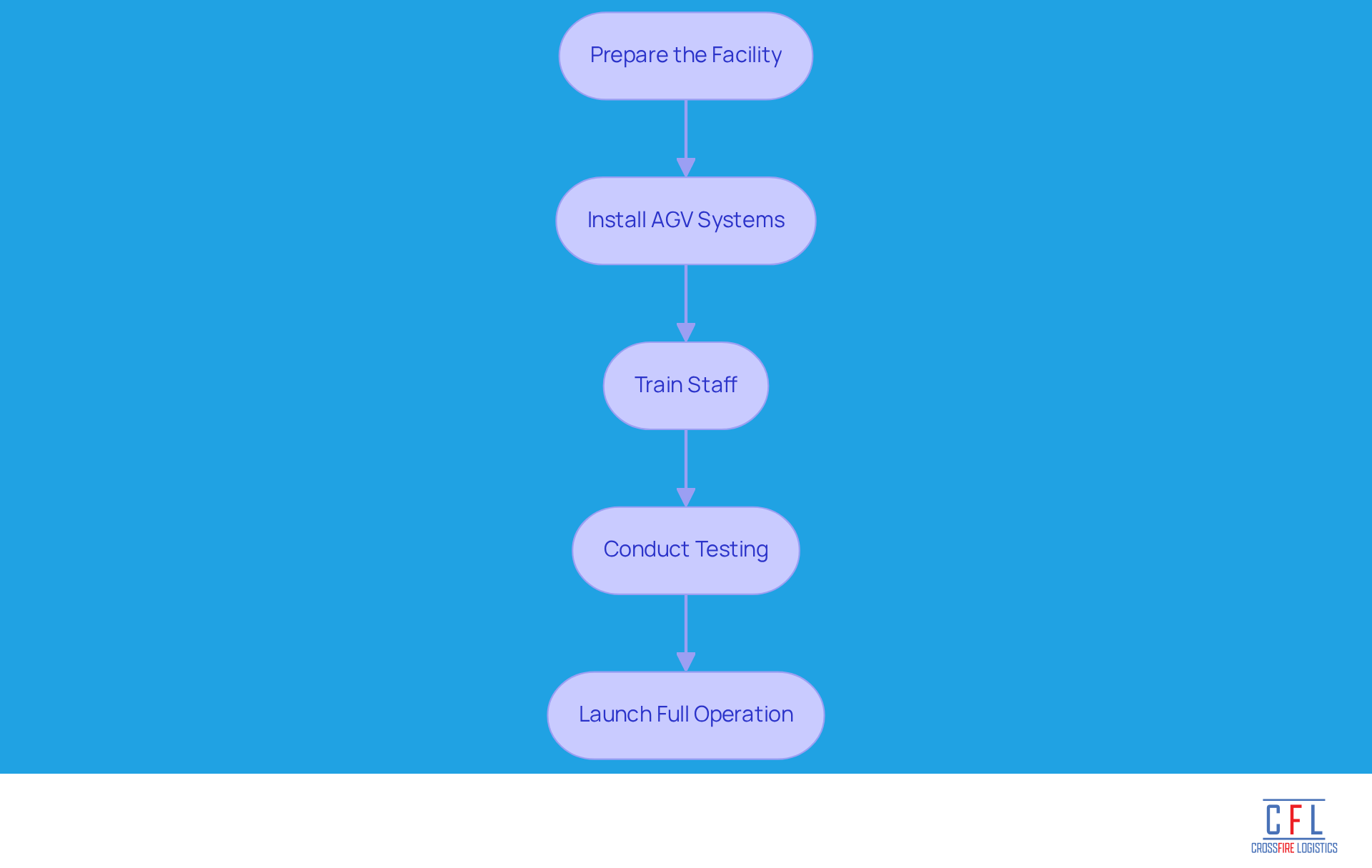

Execute the AGV Integration Process

To successfully integrate Automated Guided Vehicles (AGVs) into warehouse operations, follow these essential steps:

-

Prepare the Facility: Optimize the storage layout for AGV operation by establishing clear navigation paths and designated safety zones. This may involve modifying existing infrastructure, such as smoothing concrete floors and installing navigation markers, to ensure reliable AGV functionality.

-

Install AGV Systems: Collaborate with your AGV supplier to install the necessary hardware and software, including advanced navigation systems and charging stations. Correct setup is essential, as it generally requires several months to incorporate automated guided vehicle warehouse systems with current inventory management.

-

Train Staff: Implement comprehensive training programs for staff on AGV operation and safety protocols. Training should cover AGV technology fundamentals, system design, operation, maintenance, and safety compliance, typically lasting between 4 to 8 weeks. Involving employees early in the process can help reduce resistance and improve acceptance of automated guided vehicle warehouse solutions in the workplace.

-

Conduct Testing: Before full deployment, run pilot tests to ensure AGVs function correctly and efficiently within the warehouse environment. Tracking key performance indicators (KPIs) like order accuracy and labor productivity during this phase is essential for recognizing potential problems and enhancing performance.

-

Launch Full Operation: Once testing is complete and any issues are resolved, transition to full operation. Continuous monitoring of performance in the automated guided vehicle warehouse is essential to ensure they deliver the expected benefits, such as improved efficiency and reduced labor costs. Companies have reported significant annual savings, with many reaching a break-even point within two years of AGV implementation.

This execution phase is critical for ensuring that the automated guided vehicle warehouse operates effectively, enhancing overall productivity and safety.

Monitor and Optimize AGV Performance

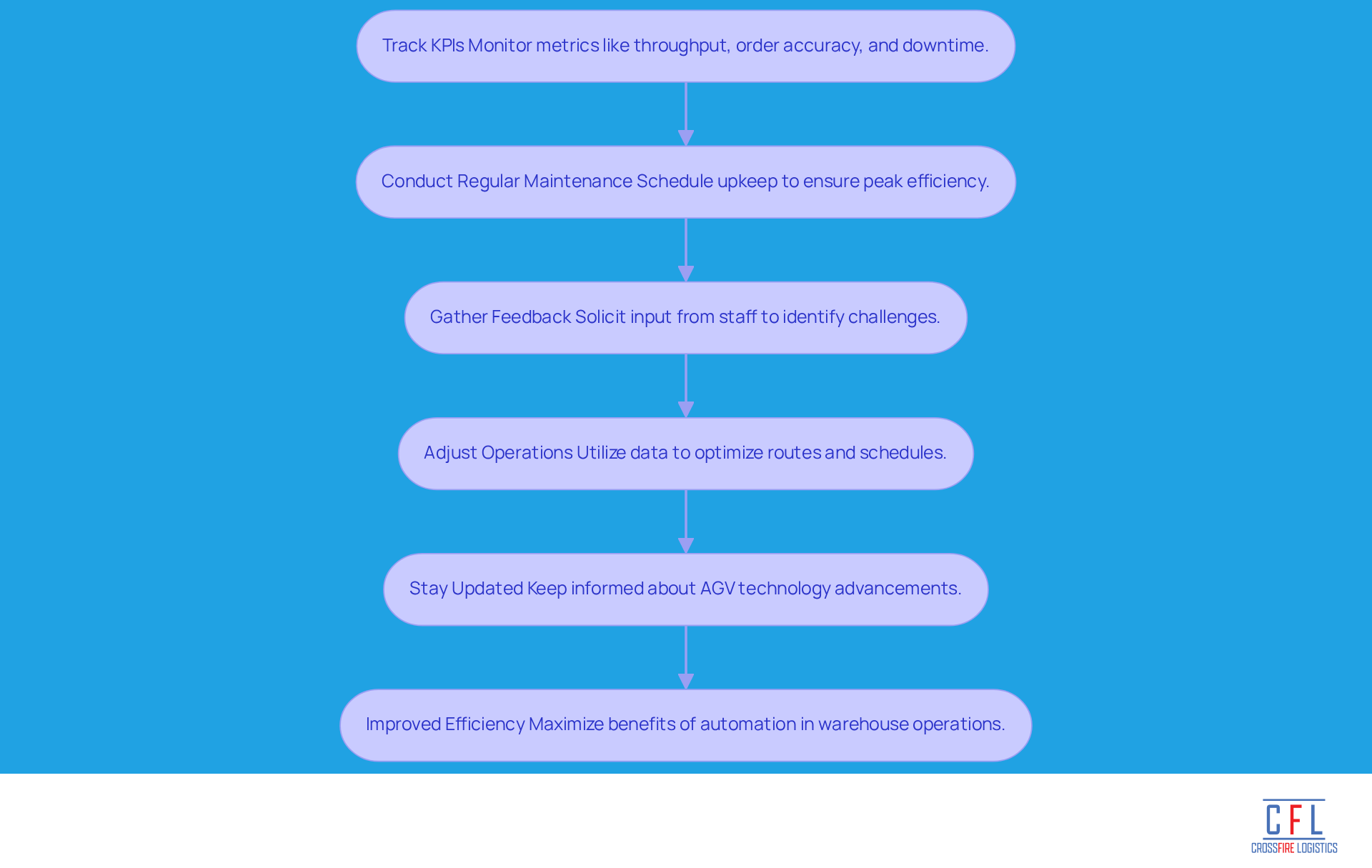

To ensure the sustained success of the automated guided vehicle warehouse after their integration, ongoing monitoring and optimization are essential. Implement the following practices:

-

Track Key Performance Indicators (KPIs): Regularly monitor metrics such as throughput, order accuracy, and downtime. These KPIs are critical for assessing AGV performance and identifying areas for improvement. For instance, companies have reported a 40% increase in order processing speed and a 75% decrease in picking errors after introducing AGVs. Furthermore, AGVs can achieve accuracy rates exceeding 99%, compared to 95% with manual procedures.

-

Conduct Regular Maintenance: Schedule routine upkeep to keep AGVs operating at peak efficiency. Maintenance statistics indicate that adhering to a regular schedule reduces downtime and operational interruptions, ensuring that AGVs remain dependable and efficient. Maintenance contracts typically cost 10-15% of hardware costs annually, which is an important consideration for budgeting.

-

Gather Feedback: Solicit input from staff regarding their interactions with AGVs. This feedback is invaluable for identifying operational challenges and enhancing the overall performance of AGV systems.

-

Adjust Operations: Utilize performance data to make informed adjustments to AGV routes, schedules, and tasks. For example, optimizing routes using real-time information can lead to significant productivity improvements, as demonstrated by a manufacturing client who experienced a 40% reduction in material flow time after implementing AGVs. AGVs operate continuously, delivering reliable performance without interruptions, which further enhances operational effectiveness compared to manual processes.

-

Stay Updated: Keep informed about advancements in AGV technology and software updates. Leveraging new features can enhance operational capabilities and improve overall performance. The storage automation market is projected to grow from $21.42 billion in 2024 to $24.09 billion by 2025, underscoring the importance of adopting AGVs now.

By actively monitoring and optimizing performance in the automated guided vehicle warehouse, you can maximize the benefits of automation, leading to improved efficiency, reduced labor costs, and enhanced safety.

Conclusion

Automated Guided Vehicles (AGVs) signify a significant advancement in warehouse operations, fundamentally changing how materials are transported and managed. Integrating AGVs into logistics allows facilities to achieve remarkable levels of efficiency, safety, and cost-effectiveness, reflecting the industry's shift towards automation.

This article outlines the various types of AGVs, including:

- Unit load vehicles

- Fork mobile robots

- Towing vehicles

Each designed to address specific operational needs. It emphasizes the substantial benefits of AGV implementation, such as:

- Increased productivity

- Significant cost savings

- Enhanced safety

- Optimized space utilization

A thorough evaluation of existing workflows and facility layouts is crucial for successful AGV integration, ensuring a smooth and effective transition.

In today's rapidly evolving logistics landscape, adopting AGVs is not merely a competitive advantage; it has become a necessity. With the market for automated guided vehicles projected to expand, organizations must prioritize assessing their warehouse needs and developing robust implementation strategies. Embracing AGV technology streamlines operations and positions businesses to thrive in an increasingly automated future. Taking action now to integrate AGVs can lead to significant improvements in efficiency, safety, and overall operational success.

Frequently Asked Questions

What are Automated Guided Vehicles (AGVs)?

Automated Guided Vehicles (AGVs) are self-operating mobile robots designed to transport materials within storage facilities without human intervention. They navigate predefined paths using technologies such as laser guidance, magnetic tape, and vision systems.

What types of AGVs are there?

There are three main types of AGVs: 1. Unit Load AGVs, which transport individual unit loads like pallets or containers. 2. Fork Mobile Robots, which mimic traditional forklifts and can lift and place loads. 3. Towing Vehicles (or tuggers), which autonomously pull carts or trailers to transport multiple smaller loads.

What is the expected market growth for AGVs?

The market for automated guided vehicle warehouses is projected to grow significantly, reaching $3.3 billion by 2028, driven by the increasing demand for automation in logistics.

How do AGVs improve warehouse efficiency?

AGVs improve warehouse efficiency by operating continuously without breaks, leading to a productivity increase of up to 25%, reducing labor costs by up to 60%, enhancing safety through advanced sensors, and optimizing space usage by maneuvering through narrow aisles.

What are the safety benefits of using AGVs?

AGVs are equipped with advanced safety sensors and systems that prevent collisions, thereby reducing workplace accidents and fostering a safer working environment.

How do AGVs contribute to cost savings in warehouses?

By automating repetitive tasks, AGVs lower labor costs by up to 60% and reduce operational expenses by minimizing errors, with facilities reporting operational cost reductions of approximately 30%.

In what sectors are AGVs applied?

AGVs are applied in various sectors, including manufacturing, where they transport raw materials to production lines, and distribution centers, where they streamline the movement of finished goods to shipping docks.

What impact do AGVs have on order processing times?

Companies like Amazon, utilizing over 200,000 robots, have experienced a 30% decrease in order processing times, demonstrating the effectiveness of AGVs in improving operational efficiency.