Introduction

Effective capacity management is a cornerstone of successful logistics operations. It influences everything from service delivery to customer satisfaction. By aligning resources with fluctuating market demands, logistics coordinators can achieve significant benefits, such as enhanced efficiency and cost savings.

However, organizations face a challenge: navigating the complexities of capacity management. To avoid common pitfalls and adapt to ever-changing conditions, they must develop strategies that ensure flexibility and responsiveness in their operations.

Define Capacity Management in Logistics

Capacity management in supply chain management involves ensuring that a business has the necessary resources - such as inventory, labor, and equipment - to meet demands effectively. At Crossfire Logistics, we understand that efficient capacity management is crucial for coordinators, as it directly impacts service delivery, operational efficiency, and customer satisfaction.

By optimizing resources, we enhance output while reducing costs. This approach guarantees that our clients benefit from our award-winning customer service and our decade-long track record of success. Our extensive capacity management, along with warehousing and transportation solutions in Hampton Roads, empowers supply chain professionals to better align their resources with market demands. Ultimately, this leads to improved performance and reduced operational delays.

Implement Effective Capacity Management Strategies

To implement effective capacity management strategies, logistics coordinators should consider the following approaches:

-

Need Prediction: Utilize advanced need prediction methods that incorporate historical sales information, market trends, and predictive analytics. This comprehensive approach enables precise predictions of future needs, allowing for proactive adjustments in capacity management and resource allocation.

-

Capacity management requires the strategic distribution of resources based on forecasted needs. This may include optimizing labor shifts, modifying warehouse layouts, or redistributing transportation resources to ensure that availability matches expected variations in needs.

-

Develop flexible capacity management solutions to adapt to changing demands. This could include leasing additional warehouse space or partnering with third-party logistics providers during peak seasons to enhance operational agility.

-

Technology integration is essential for capacity management, utilizing systems such as warehouse control systems (WCS) and transportation oversight systems (TOS) to enhance visibility and optimize operations. Real-time data access allows for immediate adjustments based on current conditions, enhancing responsiveness to market changes.

-

Ongoing enhancement requires capacity management by consistently evaluating and improving resource handling practices through the examination of performance metrics, such as actual output potential and space usage, while adjusting to changing market circumstances. This iterative method aids in spotting bottlenecks and areas for enhancement, ensuring that operations stay efficient and resilient.

-

Common Pitfalls: Be aware of frequent traps in resource management, such as overcommitting resources or failing to adjust forecasts based on market changes. Comprehending these challenges can assist coordinators in avoiding misapplication of strategies.

-

Case Studies: Consider real-world examples, such as how companies successfully implemented flexible resource solutions during peak seasons or leveraged technology for better visibility, to illustrate the effectiveness of these strategies.

Monitor and Adjust Capacity Management Practices

Effective capacity management in logistics relies on continuous monitoring and adjustment of practices through several key activities:

-

Performance Metrics: Establishing key performance indicators (KPIs) is crucial for evaluating the effectiveness of resource handling strategies. Important KPIs include order fulfillment rates, which reflect the efficiency of meeting customer needs; inventory turnover, indicating how quickly stock is sold and replenished; and resource utilization rates, assessing the effectiveness of resource use. Leading companies achieve a Perfect Order Rate of 98% or higher by utilizing AI forecasting, blockchain tracking, automated quality control, and digital twins to enhance these metrics.

-

Regularly reviewing capacity management practices is essential for evaluating their effectiveness. This process involves analyzing performance data, gathering feedback from team members, and identifying areas for improvement. Companies that adopt advanced analytics and risk modeling have reported improved responsiveness to market changes, enabling them to adapt their strategies effectively. As Ben Steffes emphasizes, managing supply chain data is vital for shippers, allowing them to leverage insights for ongoing improvement.

-

Scenario Planning: Implementing scenario planning prepares supply chain operations for potential variations in demand. By creating contingency plans that outline responses to different request scenarios, organizations can maintain agility in their operations. This proactive approach is increasingly critical as consumer expectations for rapid delivery rise, with same-day delivery services significantly shortening expected customer order cycle times. Digital twins enhance advanced simulation and scenario planning, thereby improving decision-making across all KPIs.

-

Feedback Loops: Establishing feedback loops allows for real-time adjustments based on operational performance. Utilizing technology to monitor inventory levels and transportation capabilities enables coordinators to respond swiftly to fluctuations in demand. By 2025, leading companies are projected to maintain high Fill Rates exceeding 99% through AI forecasting, networked inventory systems, 3D printing, and predictive maintenance strategies, ensuring they consistently meet customer expectations.

Recognize the Benefits of Effective Capacity Management

Effective capacity management is essential for optimizing logistics operations, delivering a range of significant benefits:

-

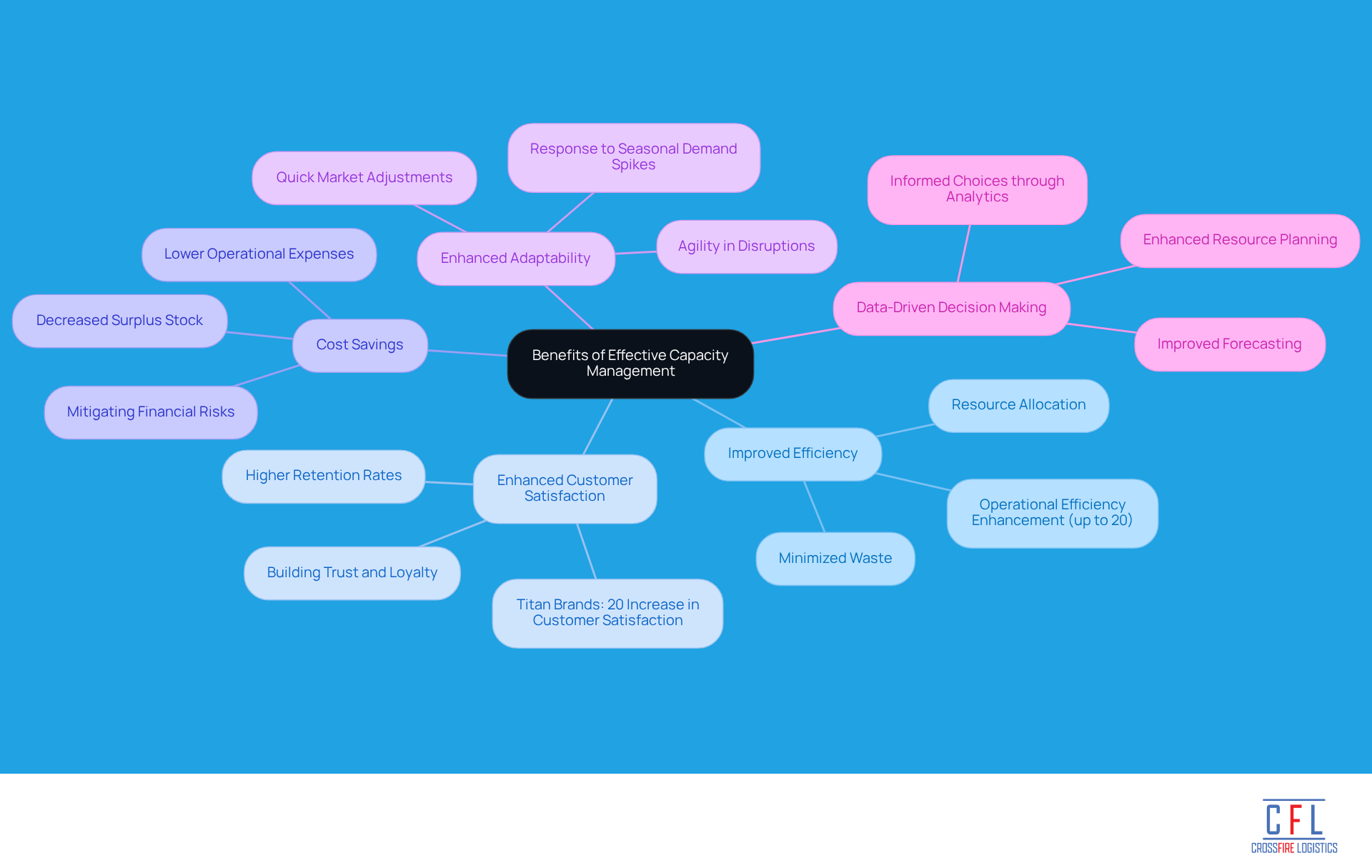

Improved Efficiency: By strategically allocating resources and minimizing waste, organizations can significantly enhance operational efficiency. This leads to quicker order fulfillment and lower costs, which are crucial in today's competitive landscape.

-

Enhanced Customer Satisfaction: Consistently meeting customer demand builds trust and loyalty, directly contributing to higher satisfaction and retention rates. In 2025, firms that excel in resource handling are anticipated to experience a significant rise in customer loyalty, as dependability becomes a crucial differentiator.

-

Cost Savings: Effective resource utilization decreases surplus stock and operational expenses, enabling companies to distribute resources more efficiently. This approach not only supports sustainable growth but also mitigates financial risks associated with overstocking.

-

Enhanced Adaptability: Organizations that implement strong resource handling strategies can quickly adjust to market variations, ensuring they stay competitive in a fast-evolving environment. This agility is vital for responding to seasonal demand spikes and unexpected disruptions.

-

Data-Driven Decision Making: Employing data analytics in resource oversight enables coordinators to make informed choices. This leads to improved forecasting and resource planning, which are essential for maintaining service quality and operational efficiency.

Statistics show that companies employing effective resource utilization strategies can attain operational efficiency enhancements of up to 20%. For instance, Titan Brands reported a 70% decrease in backorders through coordinated oversight. Such examples underscore the transformative impact of capacity management on logistics operations.

Conclusion

Mastering capacity management is essential for logistics coordinators who seek to optimize resource utilization and enhance operational efficiency. By aligning resources effectively with market demands, businesses can ensure timely service delivery and uphold high levels of customer satisfaction. The strategies outlined here provide a roadmap for coordinators to implement robust capacity management practices that adapt to the dynamic logistics landscape.

Key insights emphasize the significance of:

- Need prediction

- Flexible resource allocation

- Technology integration

- Continuous monitoring

These strategies not only help mitigate common pitfalls but also empower organizations to respond swiftly to market fluctuations. The focus on data-driven decision-making and scenario planning highlights the necessity of proactive approaches in today’s competitive environment.

Ultimately, effective capacity management transcends mere efficiency; it fosters a resilient supply chain capable of thriving amidst challenges. By adopting these best practices, logistics coordinators can achieve substantial improvements in customer satisfaction and operational performance, paving the way for sustainable growth and success in the logistics sector.

Frequently Asked Questions

What is capacity management in logistics?

Capacity management in logistics involves ensuring that a business has the necessary resources, such as inventory, labor, and equipment, to effectively meet demands.

Why is capacity management important for coordinators?

Efficient capacity management is crucial for coordinators as it directly impacts service delivery, operational efficiency, and customer satisfaction.

How does Crossfire Logistics approach capacity management?

Crossfire Logistics optimizes resources to enhance output while reducing costs, ensuring clients benefit from award-winning customer service and a decade-long track record of success.

What additional services does Crossfire Logistics provide alongside capacity management?

In addition to capacity management, Crossfire Logistics offers warehousing and transportation solutions in Hampton Roads.

What are the benefits of effective capacity management?

Effective capacity management leads to improved performance, better alignment of resources with market demands, and reduced operational delays.