Introduction

The rapid evolution of supply chain management is increasingly linked to the adoption of Electronic Data Interchange (EDI), a technology that streamlines business communications. EDI replaces traditional paper-based processes, accelerating transactions and enhancing accuracy and operational efficiency. This makes it a cornerstone of modern logistics.

However, organizations face challenges when integrating EDI into their existing systems. Critical questions arise:

- How can businesses effectively assess their current systems to identify EDI needs?

- What practices should they follow to ensure seamless implementation?

This guide explores essential steps for mastering EDI in the supply chain. It empowers organizations to optimize their operations and maintain a competitive edge.

Define Electronic Data Interchange (EDI) and Its Importance in Supply Chain

Electronic Data Interchange (EDI) signifies a major advancement in the electronic data interchange supply chain, enabling the efficient exchange of business documents between organizations through a standardized format that effectively replaces traditional paper-based methods. This transition not only accelerates transactions but also enhances accuracy, establishing electronic data interchange supply chain as a fundamental element of supply chain management.

By facilitating seamless communication among business associates, the electronic data interchange supply chain markedly reduces manual errors and expedites the order-to-cash cycle. Businesses that have adopted EDI report processing time reductions of up to 75%, leading to faster fulfillment and improved customer satisfaction.

The advantages of EDI extend beyond mere speed. It also generates substantial cost savings by eliminating expenses associated with paper, ink, and postage. Furthermore, EDI enhances inventory management through real-time data visibility, allowing organizations to respond swiftly to market demands.

Additionally, EDI supports real-time tracking and customs documentation, further broadening its applications within logistics. As more organizations embrace the electronic data interchange supply chain, they not only streamline their operations but also enhance their competitiveness in the evolving logistics landscape of 2025.

Moreover, EDI is evolving into a foundational enabler of enterprise automation and artificial intelligence. This evolution underscores the necessity for businesses to explore various deployment models - on-premises, cloud-based, and hybrid solutions - to optimize their logistics operations.

Assess Current Systems and Identify EDI Needs

To effectively integrate electronic data interchange supply chain into your logistics operations, begin with a comprehensive audit of your existing systems. This includes evaluating your ERP, inventory management, and order processing platforms. Identify the types of documents exchanged with business associates, such as:

- Purchase orders

- Invoices

- Shipping notices

Assess the efficiency of these processes to uncover areas prone to delays or errors.

Engaging stakeholders across departments is crucial. Their insights will clarify needs and expectations from an EDI system. This thorough evaluation not only helps define your requirements for the electronic data interchange supply chain but also ensures that the selected solution aligns with operational goals. Ultimately, this enhances the efficiency of the electronic data interchange supply chain.

For instance, companies like Hirschbach have successfully reduced onboarding time by 75% through systematic EDI integration, demonstrating the potential for significant operational improvements. Additionally, KBX halved its implementation time and cut 72 onboarding steps, further illustrating the advantages of EDI.

Mapping current document exchanges can uncover inefficiencies and emphasize opportunities for the electronic data interchange supply chain to optimize processes. This promotes better communication and collaboration with business associates. EDI also enables just-in-time (JIT) inventory practices, reducing warehousing costs and aligning supply with demand.

As the logistics landscape evolves, staying attuned to current trends in EDI needs assessment will empower your organization to adapt and thrive in a competitive market.

Select EDI Standards and Integration Tools

When selecting EDI standards, it’s crucial to consider widely adopted formats such as ANSI X12, EDIFACT, and XML, tailored to your industry and trading partner requirements. The electronic information interchange (EDI) software market is expected to grow significantly, with projections indicating it will reach $1.842 billion by 2030. Furthermore, the market size is predicted to increase from USD 3.11 billion in 2025 to USD 7.71 billion by 2035. This trend reflects a broader shift towards flexibility and scalability in the electronic data interchange supply chain operations, with cloud-based solutions anticipated to dominate, accounting for over 60% of total EDI units processed.

Evaluate the integration tools available, including cloud-based EDI solutions from providers like Cleo, TrueCommerce, and Dell Boomi, as well as on-premises software. Ensure their compatibility with your existing systems. Look for features such as:

- Automated mapping of information

- Real-time tracking

- Robust security protocols

These are essential for maintaining integrity and compliance with regulations like GDPR and HIPAA. As Vishnu Nair noted, the U.S. leads the revenue share in the EDI software market, highlighting the importance of selecting tools that can adapt to industry-specific demands.

The healthcare sector, for instance, is increasingly adopting EDI due to regulatory frameworks and the need for efficient information exchange. This underscores the significance of choosing tools that can adjust to industry-specific requirements. Engaging with EDI providers for demos and consultations can offer valuable insights into the best fit for your organization, enabling informed decisions that support the growth and resilience of your electronic data interchange supply chain.

Implement EDI Integration into Existing Systems

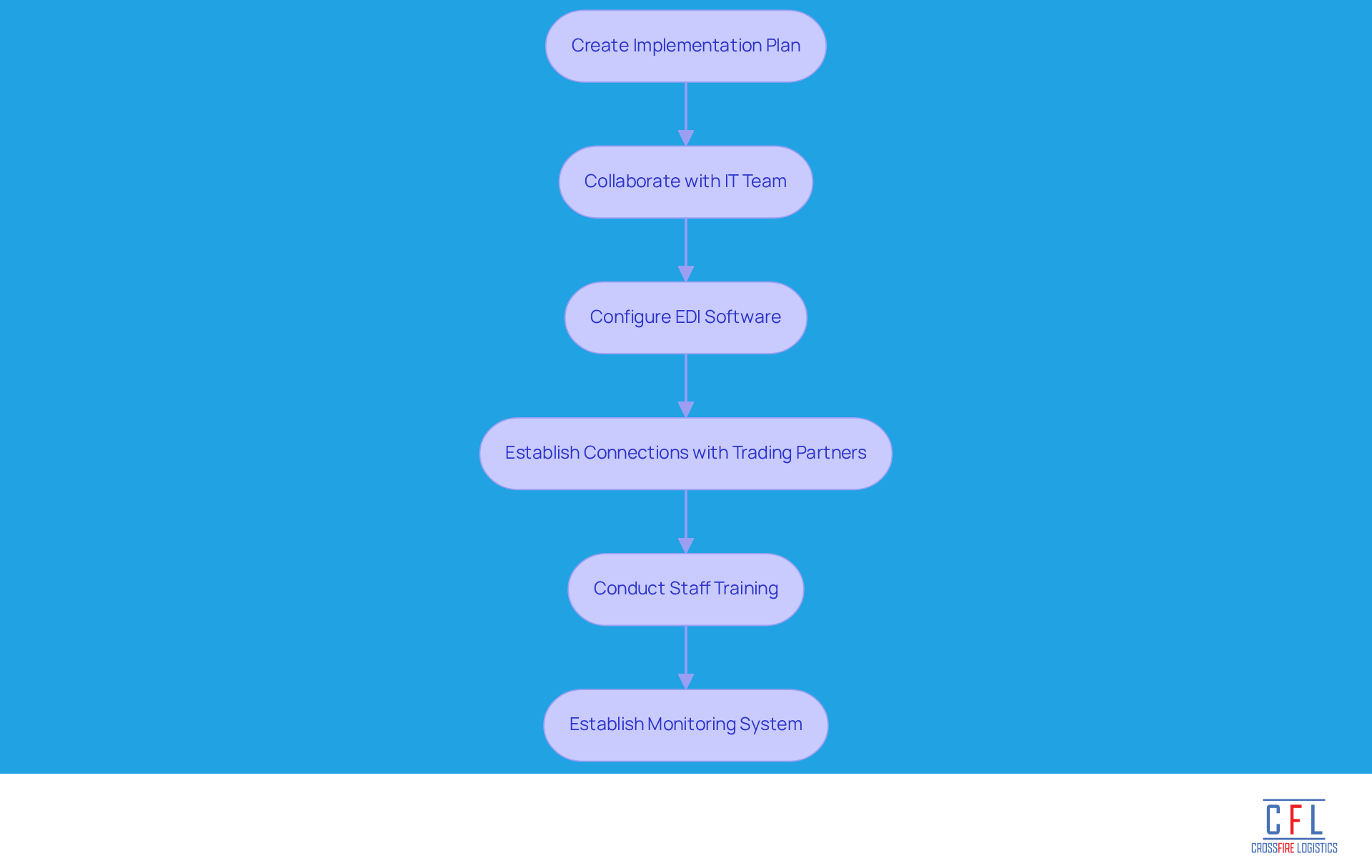

Begin by creating a comprehensive implementation plan that details the timeline, resources, and responsibilities involved in the integration process. Collaborate closely with your IT team to configure the electronic data interchange supply chain software and establish connections with your trading partners. It is crucial to ensure that information mapping is accurately set up to translate documents between your internal systems and the electronic data interchange supply chain.

Conduct training sessions for staff to familiarize them with the new processes and tools. Additionally, establishing a monitoring system is essential to track the performance of the electronic data interchange supply chain integration and promptly address any issues. A phased approach to implementation can effectively mitigate risks and allow for adjustments based on initial feedback.

Test EDI System and Onboard Trading Partners

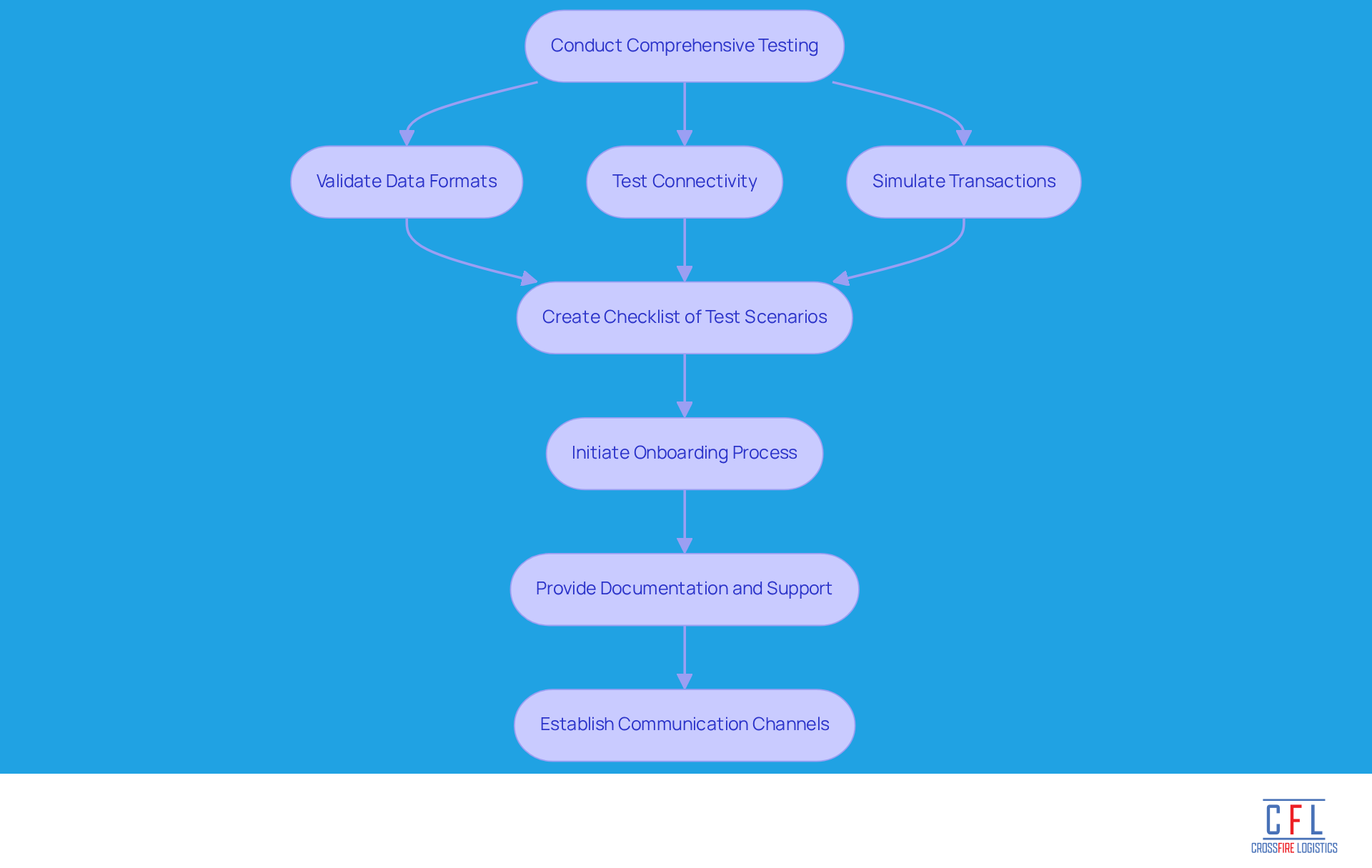

Before going live, it is essential to conduct comprehensive testing of the electronic data interchange supply chain system. This ensures that all information exchanges function correctly. Key areas to focus on include:

- Validating data formats

- Testing connectivity with business associates

- Simulating transactions to identify potential issues

Create a checklist of test scenarios that encompass all possible document types and workflows. This structured approach will help in systematically addressing any discrepancies that may arise during the electronic data interchange supply chain testing phase.

Once testing is complete, initiate the onboarding process for business associates. Provide them with the necessary documentation and support to facilitate a smooth transition. Establish clear communication channels to address any questions or concerns that may arise during this phase.

An effective onboarding process not only enables smoother transactions but also cultivates stronger connections with your business associates.

Manage and Optimize EDI System for Continuous Improvement

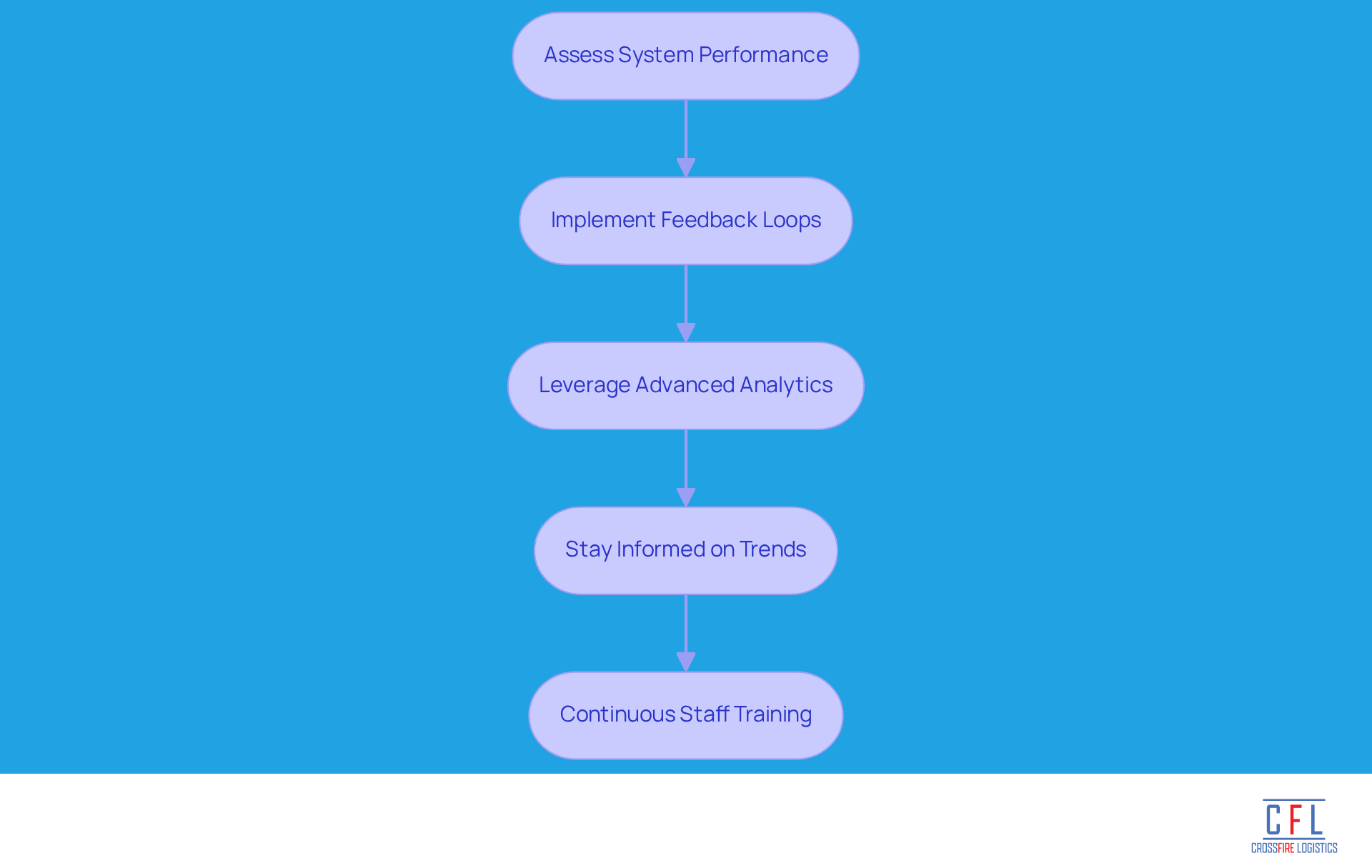

After successful implementation, establishing a management framework for your EDI system is crucial. Begin by consistently assessing system performance metrics. This helps pinpoint areas for enhancement, such as transaction speed, error rates, and client satisfaction.

Next, implement feedback loops with trading partners. Gathering insights on their experiences allows you to address any concerns effectively. Consider leveraging advanced analytics and AI tools, like those introduced in AWS B2B Data Interchange. These tools can significantly enhance data processing and decision-making capabilities.

Additionally, staying informed about industry trends and updates to EDI standards is essential. This ensures your system remains compliant and competitive. Finally, continuous training for staff on EDI best practices will contribute to sustained success.

Conclusion

Mastering Electronic Data Interchange (EDI) is crucial for organizations aiming to enhance their supply chain operations. By adopting EDI, businesses can significantly improve transaction speed, accuracy, and overall efficiency, moving away from outdated paper-based processes to streamlined electronic communications. This transition not only enhances operational performance but also positions companies to excel in a competitive landscape.

Key insights regarding the importance of EDI in supply chain management have been discussed:

- EDI reduces manual errors

- Enhances inventory management

- Supports real-time tracking

- Ultimately leads to cost savings and improved customer satisfaction

A structured approach to assessing current systems, selecting appropriate EDI standards, and implementing integration tools is essential for successful EDI deployment. Additionally, rigorous system testing and effective onboarding of trading partners are vital for ensuring a smooth transition to EDI.

In conclusion, embracing EDI is more than just a technological upgrade; it is a strategic initiative that can redefine an organization’s supply chain capabilities. Companies should stay informed about the latest trends and best practices in EDI to maximize its benefits. By committing to continuous improvement and optimization of EDI systems, businesses can achieve greater agility, responsiveness, and sustainability in their supply chain operations. Now is the time to take action and leverage EDI to drive success in the evolving marketplace.

Frequently Asked Questions

What is Electronic Data Interchange (EDI)?

Electronic Data Interchange (EDI) is a system that enables the efficient exchange of business documents between organizations in a standardized format, replacing traditional paper-based methods.

Why is EDI important in the supply chain?

EDI is important because it accelerates transactions, enhances accuracy, reduces manual errors, and expedites the order-to-cash cycle, making it a fundamental element of supply chain management.

How much can EDI reduce processing time for businesses?

Businesses that adopt EDI report processing time reductions of up to 75%, leading to faster fulfillment and improved customer satisfaction.

What are the cost benefits of using EDI?

EDI generates substantial cost savings by eliminating expenses related to paper, ink, and postage.

How does EDI improve inventory management?

EDI enhances inventory management by providing real-time data visibility, allowing organizations to respond swiftly to market demands.

What additional functionalities does EDI support in logistics?

EDI supports real-time tracking and customs documentation, broadening its applications within logistics.

How can businesses assess their current systems for EDI integration?

Businesses can assess their current systems by conducting a comprehensive audit of existing platforms like ERP, inventory management, and order processing, and identifying the types of documents exchanged with business associates.

What types of documents are typically exchanged through EDI?

Common documents exchanged through EDI include purchase orders, invoices, and shipping notices.

How can engaging stakeholders impact EDI integration?

Engaging stakeholders across departments clarifies needs and expectations from an EDI system, ensuring that the selected solution aligns with operational goals and enhances efficiency.

Can you provide examples of companies that have benefited from EDI integration?

Yes, companies like Hirschbach have reduced onboarding time by 75% through EDI integration, while KBX halved its implementation time and cut 72 onboarding steps, illustrating the operational improvements possible with EDI.

What is the significance of mapping current document exchanges in EDI?

Mapping current document exchanges helps uncover inefficiencies and highlights opportunities for EDI to optimize processes, promoting better communication and collaboration with business associates.

How does EDI facilitate just-in-time (JIT) inventory practices?

EDI enables JIT inventory practices by aligning supply with demand and reducing warehousing costs.

Why is it important to stay attuned to current trends in EDI needs assessment?

Staying attuned to current trends in EDI needs assessment empowers organizations to adapt and thrive in a competitive market as the logistics landscape evolves.