Introduction

Understanding freight rates is essential in the dynamic world of logistics, where costs can vary significantly due to numerous factors. For logistics coordinators, mastering freight rate comparison is not just about managing budgets; it also reveals opportunities for increased efficiency and savings. As the industry prepares for changes in 2025, the pressing question is: how can professionals navigate these complexities to secure optimal rates and services?

Understand Freight Rates and Their Importance

Freight prices represent the fees charged by carriers for transporting goods from one location to another. Understanding these charges is essential for logistics coordinators, as they directly influence the overall shipping costs and are crucial for freight rate comparison, significantly impacting a company's profitability. Freight charges can fluctuate considerably based on various factors, including distance, weight, and mode of transport. By grasping how these costs are determined, logistics coordinators can effectively manage budgets, negotiate with carriers, and utilize freight rate comparison to optimize shipping strategies. Additionally, recognizing the importance of shipping costs helps identify opportunities for savings and efficiency improvements within the supply chain.

In 2025, the logistics sector faces considerable uncertainty and volatility, underscoring the importance of freight costs in a fluctuating market. Recent trends show a notable decline in transpacific container prices; however, they remain below the peak levels of the previous year. This situation necessitates that logistics professionals remain informed and adaptable. Furthermore, the anticipated rise in contract prices in 2025 highlights the importance of freight rate comparison that logistics coordinators must consider when planning their budgets and strategies.

Practical examples illustrate how logistics coordinators can refine shipping strategies by utilizing freight rate comparison to gain a thorough understanding of transportation costs. By analyzing pricing trends and leveraging technology, such as AI-driven digital cargo matching tools, coordinators can identify cost-saving opportunities and enhance efficiency within the supply chain. This proactive approach not only mitigates the impact of rising expenses but also positions companies to thrive in a competitive landscape.

Identify Key Factors Influencing Freight Rates

Several key factors significantly influence freight rates, including:

-

Distance: Longer distances typically result in higher rates due to increased fuel and labor costs. Shipping charges can increase significantly as the distance between pickup and delivery locations grows, frequently resulting in greater expenses related to labor and fuel usage. As Robert Scherer observes, "The distance your shipment must travel is crucial in cost calculation."

-

Weight and Dimensions: Heavier and larger shipments incur higher charges, as they require more resources to transport. Freight density, determined by dividing total cubic feet by total weight, plays a crucial role in influencing expenses. For instance, less-than-truckload (LTL) shipping charges are determined by the dimensions and weight of the cargo, with heavier shipments typically obtaining reduced rates per 100 pounds.

-

Mode of Transport: Various methods (air, sea, rail, truck) have differing cost structures, with air transport typically being the most costly due to its speed and efficiency. In contrast, ocean freight, while cheaper, can take significantly longer, impacting overall logistics planning.

-

Market Demand: Variations in supply and demand can result in price increases, particularly during peak shipping seasons. For instance, during holiday surges, shipping costs can increase significantly, requiring proactive budgeting and planning by logistics coordinators. The heightened demand for online shopping has also led to escalating shipping expenses, as observed in recent market analyses.

-

Fuel Prices: Increasing fuel expenses directly influence freight rates, as carriers frequently transfer these charges onto shippers. In areas with elevated diesel prices because of taxes and market influences, shipping expenses can rise significantly. As Scherer points out, "Heavier loads require more fuel and increase wear on the vehicle."

-

Accessorial Charges: Additional services such as loading, unloading, and special handling can increase the total expense. Awareness of these potential hidden charges allows logistics coordinators to review quotes more effectively and manage their logistics budgets.

By understanding these factors, logistics coordinators can utilize freight rate comparison to better anticipate and manage shipping expenses, ensuring more effective budgeting and planning. For instance, planning shipments in advance allows for rate negotiation and avoidance of last-minute rush fees, ultimately leading to more efficient logistics operations.

Gather Freight Quotes from Multiple Carriers

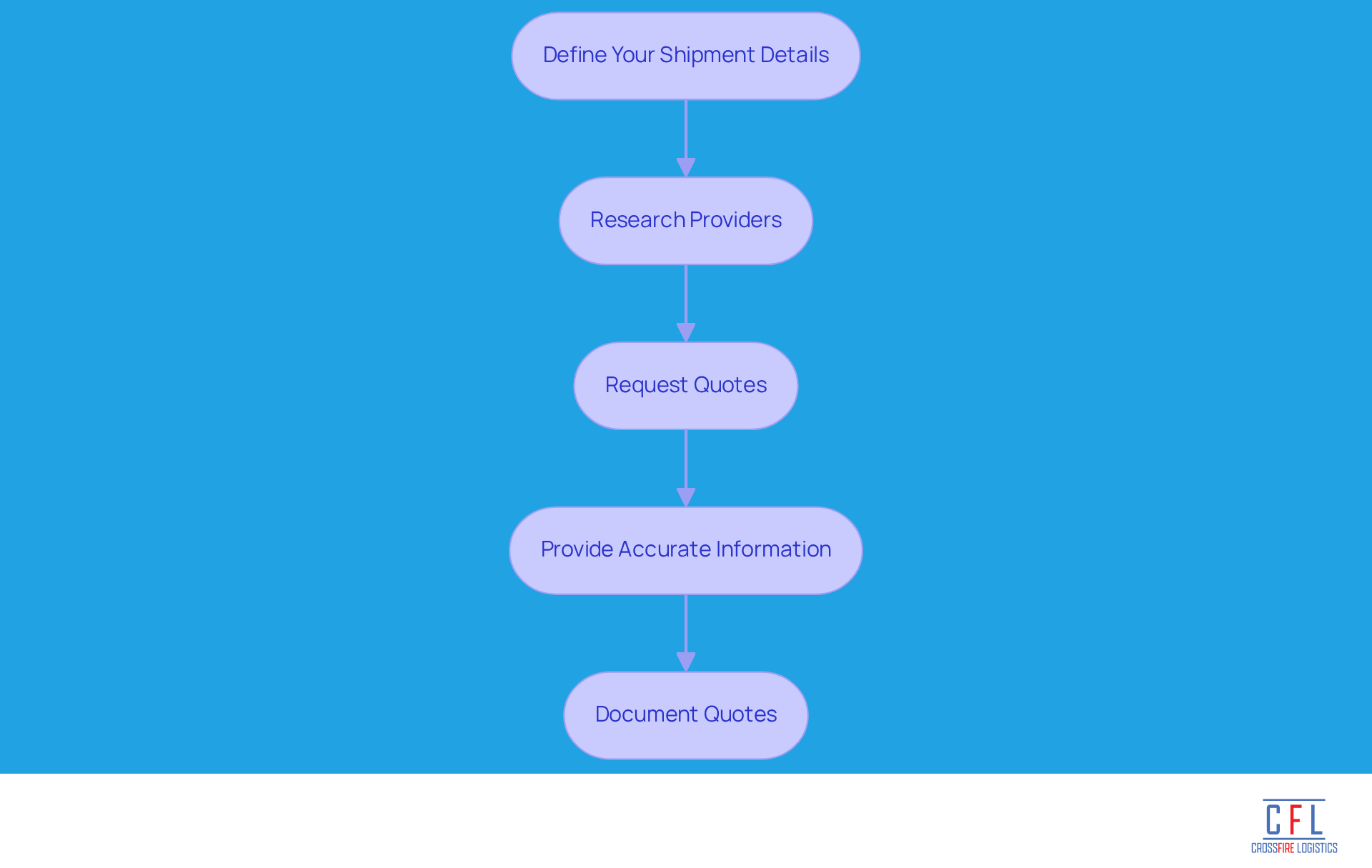

To gather freight quotes effectively, follow these steps:

-

Define Your Shipment Details: Clearly outline the specifics of your shipment, including weight, dimensions, origin, destination, and any special handling requirements. Accurate shipment details are crucial, as they significantly influence pricing and help avoid unexpected costs.

-

Research Providers: Identify a variety of providers that service your shipping routes. Consider both large and regional providers to compare options.

-

Request Quotes: Contact various providers with your shipment details. Utilize online freight quote tools or reach out to transport companies directly to obtain quotes.

-

Provide Accurate Information: Ensure that all information provided is accurate and complete to receive the most precise quotes.

-

Document Quotes: Keep a record of all quotes received, noting the prices, services offered, and any additional fees.

By collecting quotes from different providers, logistics coordinators can perform a freight rate comparison of rates and services, ultimately choosing the best option for their shipping needs.

Compare Freight Quotes Beyond Price

When comparing freight quotes, it’s crucial to consider several factors beyond just price:

-

Transit Time: Evaluate the estimated duration for each carrier to deliver the shipment. Faster transit times can often justify higher costs, especially when timely delivery is essential for business operations. For instance, the average delay for ships is around 5 days, highlighting the importance of assessing transit times in freight comparisons.

-

Service Reliability: Look into the provider's history of on-time deliveries and customer service. In 2025, companies like Maersk achieved a schedule reliability of 74.1%, while Hapag-Lloyd and MSC reported 69.6% and 65.9%, respectively. The Gemini Alliance aims for 90% schedule reliability, significantly higher than the global average of just 53%. Reliable transporters can help reduce costs associated with delays, which greatly impacts overall logistics efficiency.

-

Insurance Coverage: Examine the insurance options included in the quote. Adequate coverage is essential for protecting against potential losses during transit, providing peace of mind for logistics coordinators.

-

Accessorial Charges: Be aware of any additional fees that may apply, such as fuel surcharges, loading/unloading fees, or costs for special handling. These can accumulate and affect the overall budget.

-

Provider Reputation: Evaluate the provider's standing in the industry. Customer reviews and testimonials can offer valuable insights into their service quality and reliability.

By taking a comprehensive approach to freight rate comparison, logistics coordinators can make informed decisions that align with their operational needs and budget constraints, ultimately enhancing supply chain efficiency.

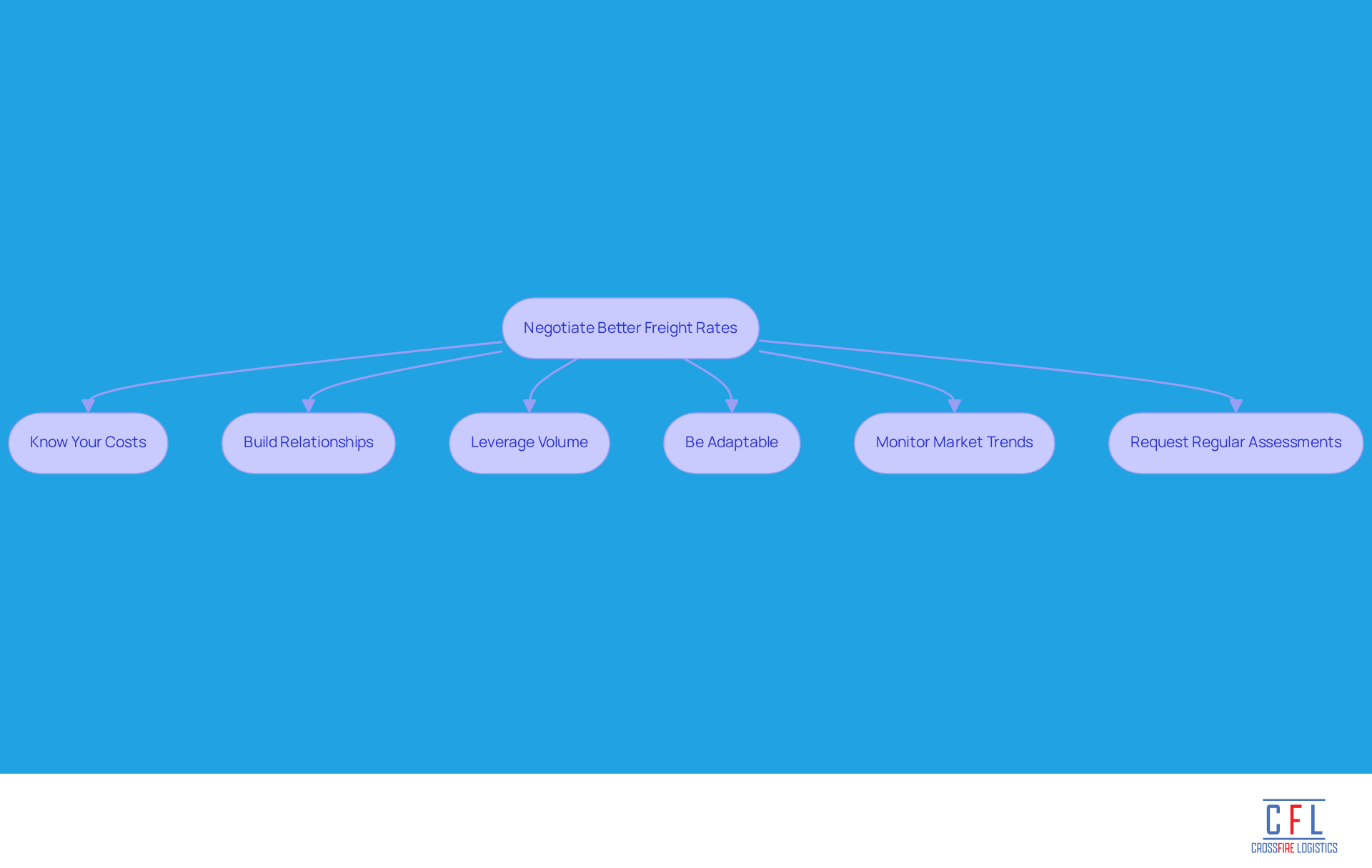

Negotiate Better Freight Rates with Carriers

To negotiate better freight rates with carriers, consider the following strategies:

- Know Your Costs: Understand your shipping costs and budget constraints. This knowledge empowers you to negotiate from a position of strength.

- Build Relationships: Establish strong connections with providers. A good rapport can lead to more favorable terms and enhanced service.

- Leverage Volume: If you have consistent shipping needs, use your shipping volume as leverage in negotiations. Carriers may offer discounts for higher volumes.

- Be Adaptable: Be willing to modify shipment timelines or routes to align with transport preferences, which can result in improved pricing.

- Monitor Market Trends: Stay informed about market conditions and trends that may influence shipping costs. Use this information to negotiate effectively.

- Request Regular Assessments: Ask carriers for regular evaluations of your prices and services. This can lead to adjustments based on changing market conditions.

By employing these negotiation strategies, logistics coordinators can improve their freight rate comparison, thereby securing better rates and enhancing their company's bottom line and operational efficiency.

Conclusion

Effectively managing freight rates is essential for logistics coordinators who seek to optimize shipping costs and enhance profitability. By mastering the intricacies of freight rate comparison, professionals can navigate the complexities of the logistics landscape, ensuring their companies remain competitive and financially sound.

Key insights from this guide underscore the importance of understanding various factors that influence freight rates, including:

- Distance

- Weight

- Mode of transport

- Market demand

Gathering multiple freight quotes and evaluating them beyond just price-considering aspects like transit time, service reliability, and provider reputation-empowers logistics coordinators to make informed decisions. Furthermore, implementing negotiation strategies can enhance cost efficiency, leading to better rates and improved operational effectiveness.

Ultimately, the significance of freight rates extends beyond mere cost calculations; it involves strategic planning and proactive management that can yield substantial savings and enhance supply chain performance. By adopting these practices, logistics coordinators can mitigate rising costs and position their businesses to thrive amidst the challenges of 2025 and beyond. Taking action now to refine freight rate strategies will pave the way for a more efficient and profitable future in logistics.

Frequently Asked Questions

What are freight rates?

Freight rates are the fees charged by carriers for transporting goods from one location to another. They are essential for logistics coordinators as they directly influence overall shipping costs and profitability.

Why is it important to understand freight rates?

Understanding freight rates is crucial for logistics coordinators to manage budgets, negotiate with carriers, and optimize shipping strategies through freight rate comparison, which can lead to cost savings and efficiency improvements.

What factors influence freight rates?

Key factors influencing freight rates include distance, weight and dimensions of the shipment, mode of transport, market demand, fuel prices, and accessorial charges for additional services.

How does distance affect freight rates?

Longer distances typically result in higher freight rates due to increased fuel and labor costs associated with transporting goods over greater distances.

How do weight and dimensions impact freight rates?

Heavier and larger shipments incur higher charges as they require more resources to transport. Freight density, calculated by dividing total cubic feet by total weight, is also a significant factor in determining costs.

What role does the mode of transport play in freight rates?

Different transport methods (air, sea, rail, truck) have varying cost structures, with air transport generally being the most expensive due to its speed, while ocean freight is cheaper but takes longer.

How does market demand affect freight rates?

Variations in supply and demand can lead to price increases, especially during peak shipping seasons, requiring logistics coordinators to budget and plan proactively.

How do fuel prices influence freight rates?

Increasing fuel expenses directly affect freight rates, as carriers often pass these costs onto shippers, particularly in areas with high diesel prices.

What are accessorial charges in freight shipping?

Accessorial charges are additional fees for services such as loading, unloading, and special handling that can increase the total shipping expense.

How can logistics coordinators use freight rate comparison effectively?

By analyzing pricing trends and leveraging technology, such as AI-driven digital cargo matching tools, logistics coordinators can identify cost-saving opportunities and enhance efficiency in the supply chain.