Introduction

Mastering warehouse scheduling resembles orchestrating a symphony; every component must work in harmony to achieve peak efficiency and productivity. As logistics operations grow increasingly complex, grasping the nuances of warehouse scheduling becomes essential for organizations seeking to streamline processes and enhance service levels.

However, with numerous factors at play - from labor allocation to technology integration - how can warehouses ensure they are not only efficient but also effective in meeting the demands of a dynamic market?

This guide explores four critical steps that can transform warehouse operations, providing insights and strategies to optimize scheduling practices and drive success.

Understand Warehouse Scheduling Basics

Warehouse scheduling is crucial for enhancing the movement of items within a storage space, ultimately aiming to boost productivity and minimize delays. The key components of this process include:

-

Slotting: This involves strategically assigning specific locations for products based on their demand and turnover rates. Efficient slotting can lead to significant improvements in storage facility effectiveness. Research indicates that proper organization can reduce retrieval times and enhance overall productivity. Notably, organizations that utilize visibility tools have reported a 20% improvement in customer service metrics, highlighting the critical nature of effective slotting.

-

Warehouse Scheduling: This process manages the arrival and departure of trucks, ensuring that loading and unloading times are optimized. By managing dock schedules effectively, storage facilities can minimize delays and streamline operations. Importantly, 72% of warehouses prioritize end-to-end visibility enabled by modern technologies, which enhances dock management efficiency.

-

Labor Scheduling: Efficient allocation of workforce resources is vital to meet operational demands. A well-structured labor schedule guarantees that the appropriate number of staff is available during peak times, thereby boosting productivity and reducing labor costs. Engaging the workforce through real-time actionable insights and gamification techniques has led to over a 15% increase in productivity, underscoring the impact of effective labor organization.

By understanding these foundational elements, logistics coordinators can identify areas for improvement and implement effective strategies. As industry specialists note, 'Efficiency is Doing Things Right; Effectiveness is Doing the Right Things.' This underscores the need for a balanced approach in storage management. Furthermore, with over 90% of facilities either currently using or planning to use Warehouse Management Systems (WMS) by 2025, the resources for efficient planning are more accessible than ever. By focusing on warehouse scheduling and slotting, storage facilities can achieve greater operational effectiveness and enhanced service levels.

Assess Your Warehouse Needs and Operations

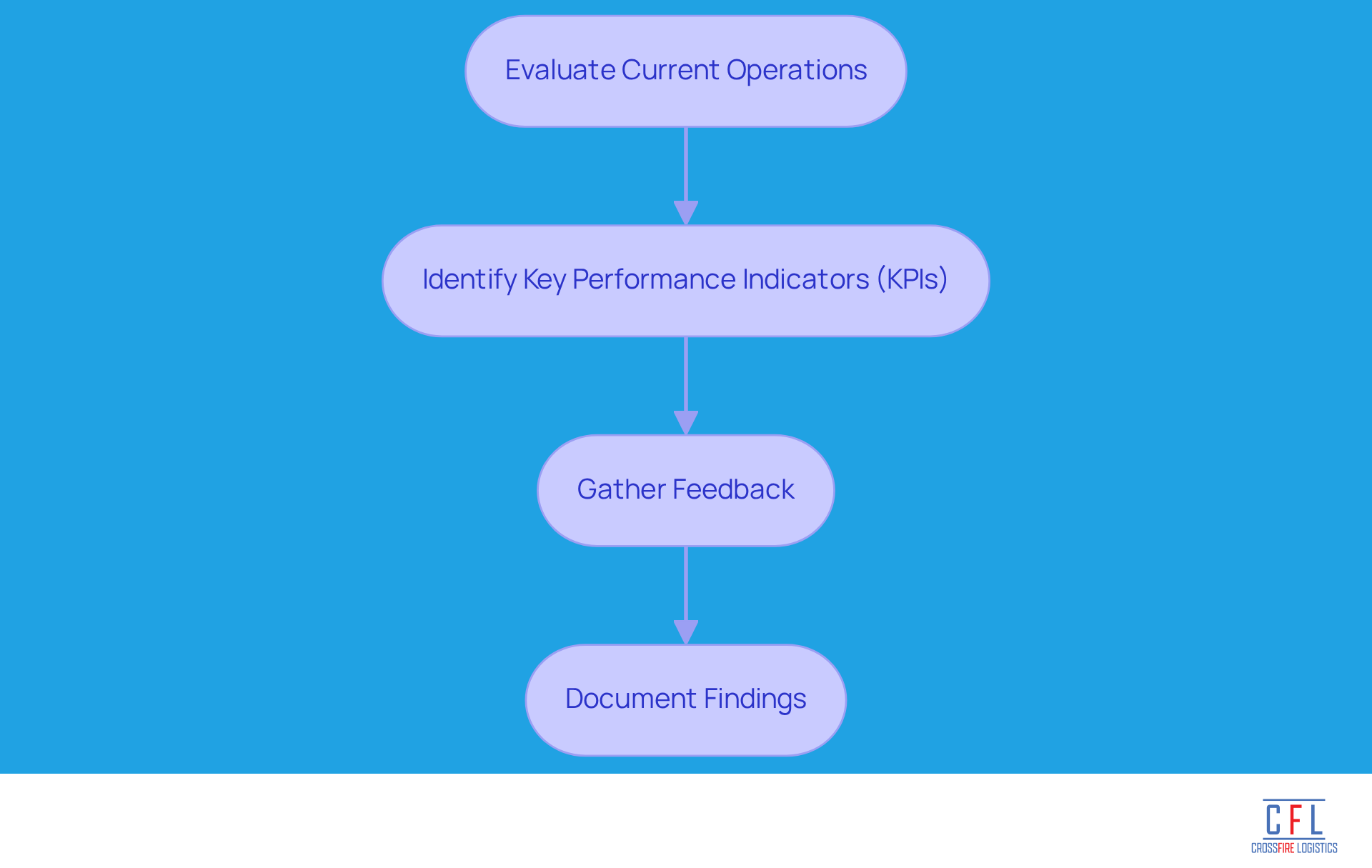

To effectively assess your warehouse needs, follow these steps:

-

Evaluate Current Operations: Conduct a thorough analysis of workflows, inventory levels, and order fulfillment processes. Identify bottlenecks and delays that obstruct productivity. For instance, measuring receiving efficiency can reveal how many items are processed per operator per hour, providing insights into operational effectiveness. Utilize Crossfire Logistics' drayage services to streamline transportation and minimize delays.

-

Identify Key Performance Indicators (KPIs): Focus on essential metrics such as order accuracy, which measures the percentage of orders correctly fulfilled; inventory turnover, indicating how often inventory is sold and replaced over a period; and labor productivity, assessing units handled per hour. These KPIs are crucial for gauging overall performance and pinpointing areas for improvement, particularly in the context of warehouse scheduling, aligning with Crossfire Logistics' comprehensive solutions.

-

Gather Feedback: Engage with warehouse staff to understand their challenges and gather suggestions for improvement. Their insights can be invaluable in identifying practical solutions that enhance daily operations, reflecting the collaborative environment that Crossfire Logistics promotes.

-

Document Findings: Create a comprehensive report detailing your current operations, challenges, and potential areas for enhancement. This documentation should include specific KPIs, such as time lost due to injury rate, which measures work hours lost due to injuries, and return feedback, which assesses customer feedback on returned products. Regularly reviewing these metrics can lead to significant operational improvements and cost reductions, supported by Crossfire Logistics' strategic partnerships that emphasize effective warehouse scheduling and streamlined logistics solutions.

Implement Effective Scheduling Strategies

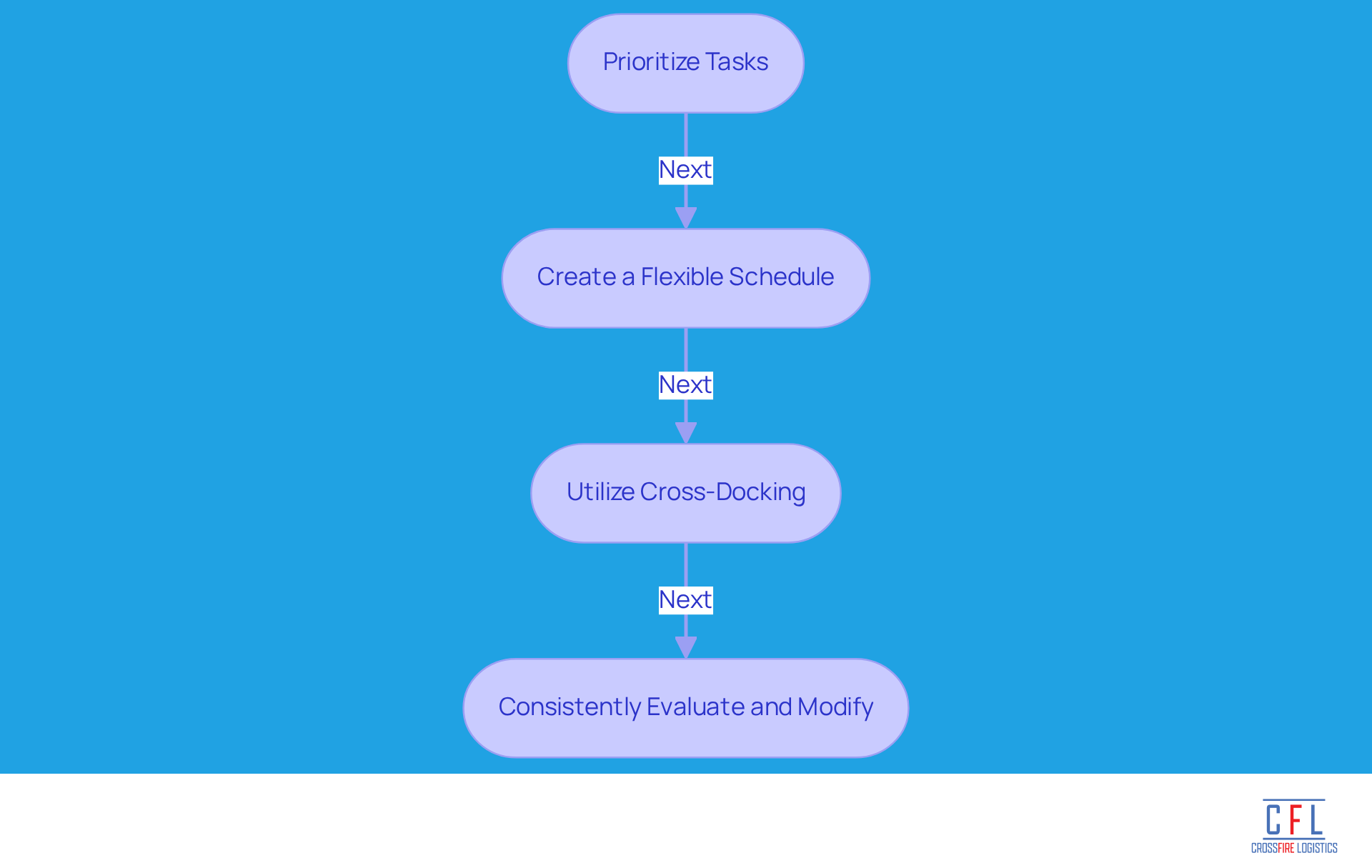

To implement effective scheduling strategies at Crossfire Logistics, consider the following:

-

Prioritize Tasks: Use a priority matrix to determine which tasks need immediate attention based on urgency and importance. This ensures that critical operations align with our commitment to on-time service.

-

Create a Flexible Schedule: Allow for adjustments based on real-time data and changing demands. This flexibility in warehouse scheduling accommodates fluctuations in workload, leveraging our extensive 200,000 square feet of warehouse space in Hampton Roads.

-

Utilize Cross-Docking: Streamline operations by transferring products directly from incoming to outgoing shipments. This reduces storage time and improves effectiveness in our drayage services.

-

Consistently Evaluate and Modify: Continuously oversee performance and make essential changes to the timing process. This enhances effectiveness and demonstrates our commitment to excellence and customer satisfaction.

Leverage Technology for Scheduling Efficiency

To enhance scheduling efficiency through technology, consider the following tools:

-

Warehouse Management Systems (WMS): A contemporary WMS streamlines inventory tracking, order processing, and task planning, significantly enhancing operational performance. With 80% of organizations in warehousing planning to invest in new technologies, a robust WMS serves as a strategic enabler for seamless integration across various logistics functions.

-

Dock Scheduling Software: Specialized dock scheduling software is essential for managing dock appointments effectively. By reducing wait times and improving truck turnaround, these systems enhance logistics efficiency. Statistics indicate that 67% of respondents reported losing customers due to overselling or stockouts, underscoring the importance of timely dock management in maintaining service levels.

-

Data Analytics Tools: Leveraging data analytics allows warehouses to forecast demand accurately and optimize labor allocation based on historical data. This proactive approach streamlines operations and prepares businesses to adapt to fluctuating market demands, ensuring competitiveness in a rapidly evolving landscape.

-

Mobile Applications: Providing personnel with mobile applications for real-time updates and communication ensures that everyone is aware of timetable changes. This capability improves responsiveness and reduces disruptions, which is crucial in a setting where 60% of professionals in warehousing cite labor productivity as a primary challenge.

By integrating these technologies, warehouse scheduling can significantly improve, leading to enhanced operational efficiency and customer satisfaction.

Conclusion

In conclusion, mastering warehouse scheduling is crucial for optimizing operations and boosting overall productivity. By concentrating on essential components such as slotting, labor scheduling, and effective dock management, organizations can significantly minimize delays and enhance service levels. This guide underscores the necessity of a strategic approach to warehouse scheduling, ensuring that facilities not only address current demands but also adapt to future challenges.

The article outlines critical strategies for assessing warehouse needs, implementing effective scheduling practices, and leveraging technology to improve efficiency. Evaluating current operations, identifying key performance indicators, and gathering staff feedback are foundational steps that lead to meaningful enhancements. Furthermore, utilizing advanced tools like Warehouse Management Systems and dock scheduling software can streamline processes and facilitate better decision-making.

The importance of optimizing warehouse scheduling cannot be overstated. As the logistics landscape evolves, adopting these strategies and technologies will empower organizations to stay competitive. By prioritizing effective scheduling practices, warehouses can enhance operational efficiency while also driving customer satisfaction and long-term success. Taking action now to implement these best practices will pave the way for a more productive and responsive warehousing environment.

Frequently Asked Questions

What is the purpose of warehouse scheduling?

Warehouse scheduling aims to enhance the movement of items within a storage space, boosting productivity and minimizing delays.

What is slotting in warehouse management?

Slotting involves strategically assigning specific locations for products based on their demand and turnover rates, which can significantly improve storage facility effectiveness and reduce retrieval times.

How does effective slotting impact customer service?

Organizations that utilize visibility tools for slotting have reported a 20% improvement in customer service metrics, highlighting its critical nature.

What is the role of warehouse scheduling in dock management?

Warehouse scheduling manages the arrival and departure of trucks, optimizing loading and unloading times to minimize delays and streamline operations.

How important is end-to-end visibility in warehouse operations?

72% of warehouses prioritize end-to-end visibility enabled by modern technologies, which enhances dock management efficiency.

Why is labor scheduling important in warehouse management?

Efficient labor scheduling ensures that the appropriate number of staff is available during peak times, boosting productivity and reducing labor costs.

What impact does engaging the workforce have on productivity?

Engaging the workforce through real-time actionable insights and gamification techniques has led to over a 15% increase in productivity.

How can logistics coordinators improve warehouse operations?

By understanding foundational elements of warehouse scheduling, such as slotting and labor allocation, logistics coordinators can identify areas for improvement and implement effective strategies.

What is the significance of Warehouse Management Systems (WMS) in warehouse scheduling?

Over 90% of facilities are either currently using or planning to use Warehouse Management Systems (WMS) by 2025, making resources for efficient planning more accessible than ever.

What is the key takeaway regarding efficiency and effectiveness in warehouse management?

The quote "Efficiency is Doing Things Right; Effectiveness is Doing the Right Things" emphasizes the need for a balanced approach in storage management.