Introduction

The logistics landscape is evolving rapidly, with businesses increasingly relying on technology to streamline operations. At the forefront of this transformation is the Warehouse Management System (WMS), which offers solutions that not only manage inventory but also enhance operational efficiency and customer satisfaction.

As organizations strive to remain competitive, a critical question arises: how can the right WMS simplify warehouse processes while driving significant improvements in supply chain performance? Exploring the features, benefits, and historical evolution of WMS reveals its essential role as a strategic asset in modern supply chain management.

Define Warehouse Management System (WMS)

A Warehouse Management System (WMS) in supply chain is a software application that is crucial for managing and optimizing warehouse operations. For companies like Crossfire Logistics, which offers comprehensive warehousing and drayage services in Hampton Roads, utilizing a WMS in supply chain is essential.

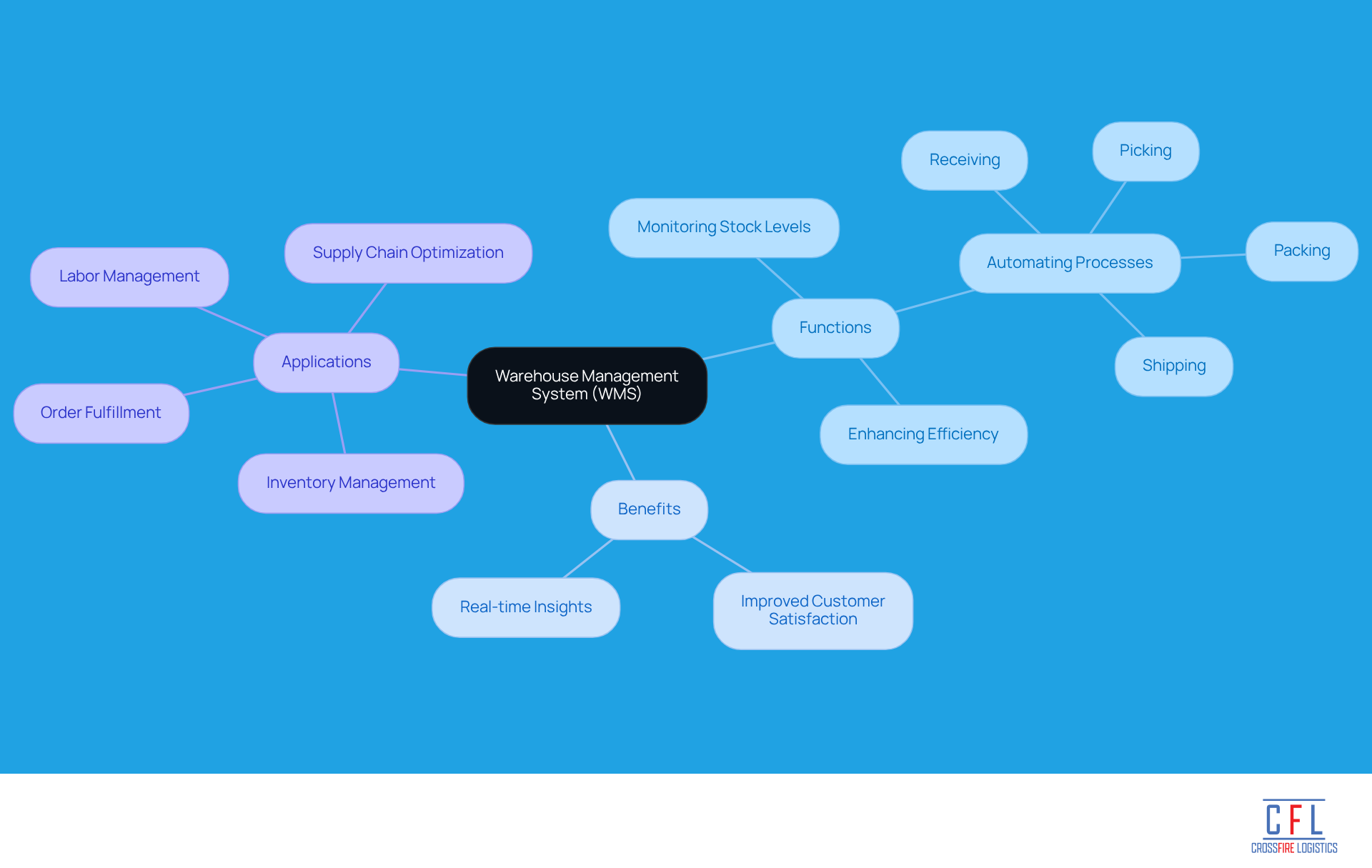

This system enables the monitoring of stock levels, orders, and shipments, ensuring that goods are stored and retrieved efficiently. By automating processes such as receiving, picking, packing, and shipping, a WMS significantly enhances operational efficiency and accuracy. As a result, it leads to improved customer satisfaction.

Moreover, the WMS in supply chain acts as the backbone of modern warehousing, providing real-time insights into stock and optimizing workflows throughout. This capability is vital for Crossfire Logistics' commitment to delivering timely and budget-friendly service.

Contextualize WMS in Supply Chain Operations

In supply chain operations, a Storage Control System (SCS) plays a vital role in ensuring efficient inventory oversight. It supervises the journey of goods from their arrival at the facility to their dispatch to clients. This system provides essential information that supports informed decision-making, including real-time insights into stock levels, order statuses, and storage capacity.

The integration of WMS in supply chain processes with Transportation Coordination Systems (TCS) and Enterprise Resource Planning (ERP) software significantly enhances visibility and coordination. This interconnectedness enables businesses to swiftly adapt to market demands, streamline operations, and reduce costs. Such capabilities are crucial for maintaining a competitive edge in the rapidly evolving logistics landscape.

For instance, companies like Navico Group have successfully implemented WMS in supply chain solutions to improve warehouse efficiency and customer satisfaction. This showcases the tangible benefits of these systems in optimizing stock management.

As the global market for WMS in supply chain is projected to grow at a CAGR of 17.1% from 2025 to 2030, the trend towards integrating these systems is increasingly vital for organizations looking to enhance their operational capabilities and responsiveness.

Trace the Evolution of Warehouse Management Systems

The development of Warehouse Management Systems (WMS) began in the 1960s with the introduction of the first computerized stock management systems, coinciding with the significant technological advancement represented by Automated Storage and Retrieval Systems (AS/RS). Initially, these systems were basic, primarily focused on tracking stock levels. However, as technology progressed, particularly during the 1980s and 1990s, WMS in supply chain evolved to include more sophisticated functionalities such as:

- Real-time data processing

- Automated picking systems

- Integration with other supply chain technologies

This era is often referred to as the 'Golden Age' of WMS development, marked by substantial improvements in computing power and software capabilities. Notably, J.C. Penney launched its first real-time WMS in 1974, revolutionizing inventory tracking.

By the 2000s, the emergence of Software as a Service (SaaS) architecture made WMS more accessible, enabling businesses to lower infrastructure costs while enhancing operational flexibility. Today, modern WMS solutions leverage cloud computing, artificial intelligence, and machine learning to optimize storage operations, improve accuracy, and boost overall efficiency. The cloud segment accounted for the highest revenue share in 2024 and is projected to experience rapid growth, with a compound annual growth rate (CAGR) of 20.6% from 2025 to 2030. These advancements not only reflect the increasing complexity of supply chains but also highlight the rising demand for sophisticated management tools. As businesses adapt to changing market conditions, the role of WMS in supply chain management as a strategic enabler in logistics becomes increasingly vital.

![]()

Identify Core Features and Functionalities of WMS

Core features of a Warehouse Management System include:

-

Inventory Management: This feature allows for real-time tracking of stock levels, locations, and movements. It ensures accuracy and reduces discrepancies in inventory.

-

Order Fulfillment: Streamlining the picking, packing, and shipping processes enhances speed and efficiency, leading to improved customer satisfaction.

-

Receiving and Put-Away: Automating the processes of receiving goods and storing them in optimal locations within the storage facility maximizes space utilization and efficiency.

-

Labor Management: Monitoring employee performance and productivity helps optimize labor allocation, ultimately reducing operational costs.

-

Reporting and Analytics: This feature offers insights into storage operations through data analysis, assisting managers in making informed decisions.

Collectively, these features contribute to a more organized, efficient, and responsive warehouse environment, enhancing the effectiveness of WMS in supply chain.

Highlight Benefits of Implementing a WMS

Implementing a Warehouse Management System (WMS) provides several key benefits that can significantly enhance business operations:

- Improved Inventory Accuracy: Automating tracking and management processes allows businesses to achieve higher accuracy in inventory counts. This reduces the risk of stockouts and overstock situations.

- Enhanced Operational Efficiency: A WMS streamlines workflows, minimizes manual errors, and accelerates order fulfillment. As a result, businesses experience faster turnaround times.

- Cost Reduction: By optimizing labor and space utilization, a WMS can substantially lower operational costs associated with warehousing.

- Better Customer Service: With improved accuracy and quicker order processing, businesses can enhance customer satisfaction and foster loyalty.

- Scalability: Modern WMS solutions are designed to grow alongside the business, facilitating the easy integration of new functionalities as operational needs evolve.

These benefits highlight the critical role of WMS in supply chain management in securing a competitive advantage within the logistics sector.

Conclusion

A Warehouse Management System (WMS) is a crucial asset that revolutionizes supply chain operations by improving efficiency, accuracy, and overall effectiveness in warehouse management. By automating key processes and integrating smoothly with other systems, WMS not only streamlines operations but also enhances a company's capacity to meet customer demands quickly and reliably.

This article explores the various dimensions of WMS, emphasizing its:

- Definition

- Evolution

- Core features

- Numerous benefits it provides

Important insights include the role of WMS in:

- Inventory management

- Order fulfillment

- Labor optimization

All of which lead to enhanced operational efficiency and customer satisfaction. Furthermore, the historical context of WMS development illustrates its technological progress and increasing importance in contemporary logistics.

As supply chains evolve and encounter new challenges, the significance of adopting a robust Warehouse Management System cannot be overstated. Organizations are urged to leverage WMS technology not only to improve their operational capabilities but also to gain a competitive advantage in the marketplace. By investing in a WMS, businesses position themselves for success in a complex logistics environment, ultimately fostering greater efficiency and customer loyalty.

Frequently Asked Questions

What is a Warehouse Management System (WMS)?

A Warehouse Management System (WMS) is a software application that manages and optimizes warehouse operations, including monitoring stock levels, orders, and shipments to ensure efficient storage and retrieval of goods.

How does a WMS improve operational efficiency?

A WMS enhances operational efficiency by automating processes such as receiving, picking, packing, and shipping, which leads to improved accuracy and customer satisfaction.

What role does WMS play in supply chain operations?

In supply chain operations, WMS acts as a backbone for modern warehousing, providing real-time insights into stock and optimizing workflows, which is essential for timely and budget-friendly service.

How does a Storage Control System (SCS) relate to WMS?

A Storage Control System (SCS) ensures efficient inventory oversight by supervising the journey of goods from arrival to dispatch, providing essential information that supports decision-making alongside WMS.

What are the benefits of integrating WMS with other systems?

Integrating WMS with Transportation Coordination Systems (TCS) and Enterprise Resource Planning (ERP) software enhances visibility and coordination, allowing businesses to adapt to market demands, streamline operations, and reduce costs.

Can you provide an example of a company that successfully implemented WMS?

Navico Group is an example of a company that has successfully implemented WMS in supply chain solutions to improve warehouse efficiency and customer satisfaction.

What is the projected growth of the WMS market in the coming years?

The global market for WMS in supply chain is projected to grow at a CAGR of 17.1% from 2025 to 2030, indicating a trend towards integrating these systems for enhanced operational capabilities.