Introduction

Understanding the dynamics of utilization and capacity is crucial for logistics coordinators aiming to optimize their operations. These concepts define the potential of logistics systems and directly influence efficiency, cost management, and service quality.

The challenge lies in balancing resource utilization with the need to maintain adequate capacity to meet evolving customer demands. Logistics professionals must effectively harness these metrics to enhance operational performance while avoiding the pitfalls of overuse and inefficiency.

By focusing on these key areas, logistics coordinators can navigate the complexities of their roles and drive improvements in their operations.

Define Utilization and Capacity in Logistics

In supply chain management, potential refers to the maximum quantity of goods or services that can be produced or managed within a specific timeframe under optimal conditions. This concept encompasses all available resources, including labor, equipment, and storage capacity.

For instance, Crossfire Logistics operates 200,000 square feet of public and contract warehouse space across four locations in Hampton Roads. This extensive capacity allows them to effectively manage a variety of logistics needs.

Conversely, the concept of utilization vs capacity measures how effectively these resources are employed, expressed as a percentage of the total potential utilized. For example, if a warehouse has a capacity of 100,000 square feet but only utilizes 80,000 square feet, its utilization rate is 80%. Understanding the concept of utilization vs capacity is crucial for coordinators, as it directly impacts operational efficiency and resource allocation. High resource utilization vs capacity indicates effective use, while low utilization vs capacity may suggest inefficiencies or excess capacity.

A transportation firm like Crossfire Logistics, which adeptly manages its warehouse capacity and forges strategic partnerships, can swiftly respond to fluctuations in demand. This ensures timely deliveries and cost reductions. Such a strategic approach not only boosts productivity but also aligns with contemporary industry standards that emphasize operational efficiency and customer satisfaction.

Analyze the Impact of Utilization on Logistics Operations

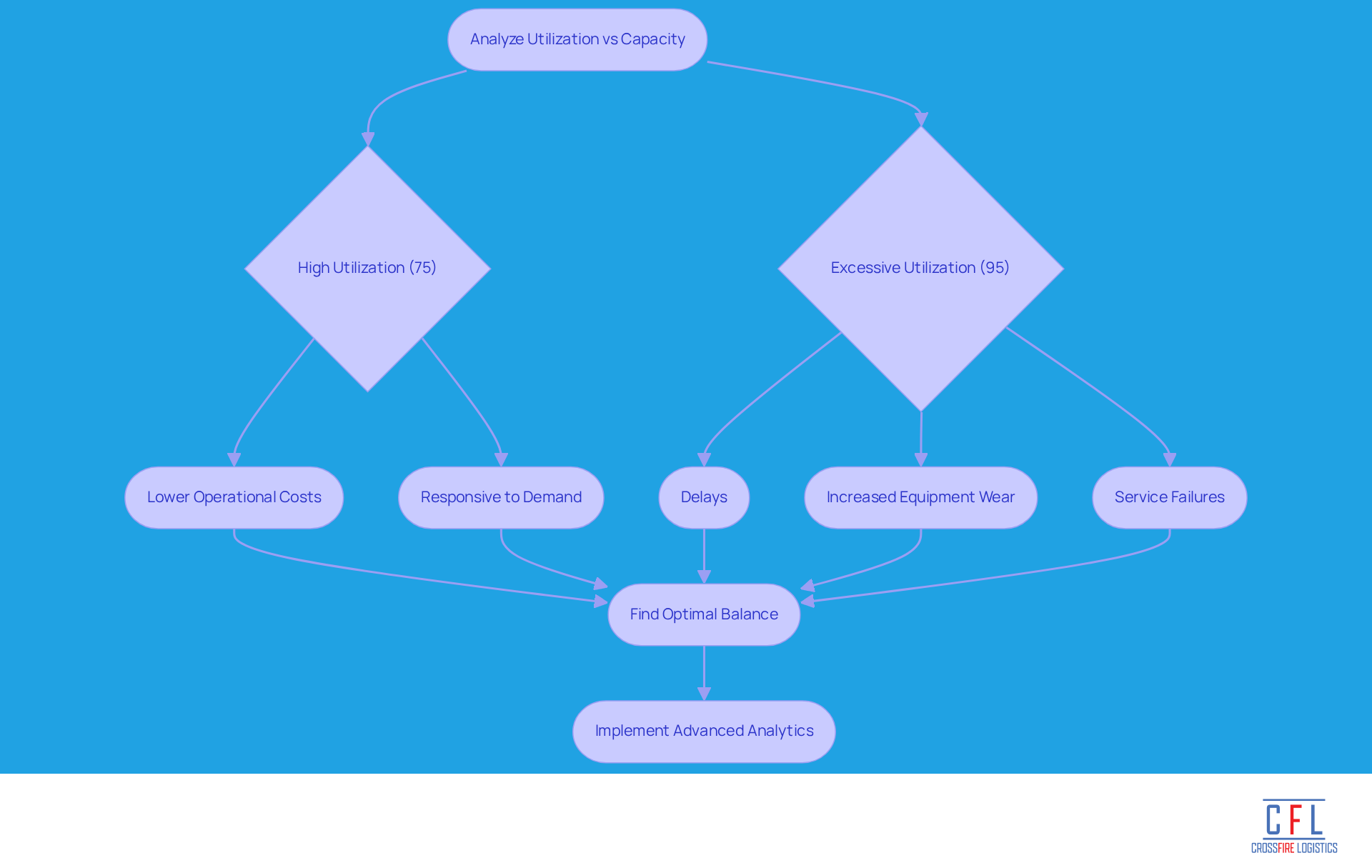

The relationship between utilization vs capacity plays a crucial role in supply chain operations, directly influencing cost efficiency and service delivery. High usage rates, when analyzed in terms of utilization vs capacity, typically indicate effective resource use, resulting in lower operational costs per unit. For instance, logistics firms that maintain usage rates around 75% can enhance their resources while remaining responsive to demand variations.

However, when examining utilization vs capacity, excessively high usage, such as operating at 95%, can strain systems. This can lead to delays, increased equipment wear, and potential service failures. Therefore, finding the right balance in terms of utilization vs capacity is essential. While high utilization vs capacity can enhance efficiency, it must be managed carefully to avoid compromising service quality.

Statistics suggest that companies achieving maximum efficiency can lower costs by up to 20%. This highlights the financial advantages of effective management. Successful supply chain providers often implement advanced analytics and real-time monitoring to effectively manage utilization vs capacity and maintain optimal usage rates. This ensures they can adapt to unexpected demand spikes without sacrificing performance.

As one supply chain expert remarked, "Identifying the ideal balance in usage is crucial; it’s about optimizing efficiency while ensuring we can still satisfy our clients' requirements." This underscores the importance of strategic management of utilization vs capacity in achieving operational excellence.

Examine the Role of Capacity in Logistics Performance

In supply chain performance, understanding the relationship between utilization vs capacity is crucial as it determines the maximum output achievable within a given timeframe. Efficient resource management enables logistics providers to meet customer demands swiftly, thereby minimizing delays. For example, a storage facility with a capacity of 200,000 square feet that has a utilization vs capacity of only 150,000 square feet of stock risks facing shortages and lost sales during peak periods.

On the other hand, overestimating capacity when considering utilization vs capacity can result in resource wastage and increased operational costs. Therefore, precise resource planning is vital for aligning operational capabilities with market demands, ultimately enhancing service standards and operational efficiency. Current industry trends indicate that 11% of transportation firms prioritize compliance with regulations, up from 7% in April 2025. This shift highlights a growing recognition of the importance of resource planning in maintaining compliance and service quality.

Moreover, effective planning strategies, such as the Lead Strategy and Lag Strategy, empower organizations to anticipate demand surges and respond proactively, thus averting bottlenecks and ensuring seamless operations. As supply chain management evolves, the integration of technology and data analysis into resource planning processes is becoming increasingly essential. This integration allows companies to respond swiftly to market fluctuations and consumer demands.

Furthermore, understanding the three categories of planning - short-term, medium-term, and long-term - provides coordinators with a comprehensive framework for effective resource management.

Compare Utilization and Capacity: Strengths, Weaknesses, and Suitability

In the logistics field, understanding the relationship between utilization vs capacity reveals various strengths and weaknesses. Utilization is a key metric for assessing efficiency and identifying operational bottlenecks. A high usage rate often indicates effective resource distribution; however, it can also signify overuse, potentially leading to equipment failures and service delays. For instance, the U.S. output utilization rate was reported at 77.4% in August 2025, which is 2.1 percentage points below its long-run average (1972-2024). This suggests that while resources are being utilized effectively, there remains a risk of strain on operations.

Conversely, capability provides a comprehensive view of operational limits and growth potential. Strong capability enables service providers to expand operations and respond swiftly to changing demands. However, if not managed carefully, excess resources can result in higher fixed costs, impacting overall profitability. For example, the transportation sector is projected to grow at a 6.3% CAGR, driven by e-commerce demand and infrastructure investment. This underscores the need for strategic resource management to capitalize on market opportunities.

Logistics coordinators face the challenge of balancing the metrics of utilization vs capacity. Optimizing utilization can lead to cost reductions, yet it is equally important to maintain adequate capacity to meet customer expectations. Industry specialists emphasize that achieving this balance is crucial for maintaining a competitive edge in the supply chain landscape. The ongoing shift towards e-commerce and consumer demand for rapid delivery highlights the significance of this equilibrium, as 78% of consumers now expect same- or next-day delivery.

Ultimately, the strengths and weaknesses of utilization vs capacity must be navigated carefully to enhance operational efficiency and ensure customer satisfaction in an increasingly complex logistics environment.

Conclusion

Understanding the distinction between utilization and capacity is vital for logistics coordinators aiming to optimize operations. This interplay not only influences resource management but also significantly impacts overall efficiency and customer satisfaction. A thorough grasp of both concepts enables logistics professionals to make informed decisions that enhance service delivery and reduce operational costs.

This article delves into the definitions and implications of utilization and capacity, highlighting their critical roles in logistics operations. Effective utilization can lead to cost savings and improved service levels. However, it is essential to be cautious of excessive utilization, which may strain resources. Furthermore, accurate capacity planning is crucial to meet fluctuating market demands and maintain operational effectiveness.

In conclusion, balancing utilization and capacity is not merely theoretical; it is a practical necessity in the logistics sector. As e-commerce continues to grow and customer expectations evolve, logistics coordinators must prioritize strategic resource management. This ensures they can meet demands without sacrificing quality. Embracing advanced analytics and proactive planning will be essential in navigating the complexities of modern logistics, ultimately leading to sustained operational excellence and competitive advantage.

Frequently Asked Questions

What is the definition of potential in logistics?

In logistics, potential refers to the maximum quantity of goods or services that can be produced or managed within a specific timeframe under optimal conditions, encompassing all available resources, including labor, equipment, and storage capacity.

How does Crossfire Logistics utilize its warehouse space?

Crossfire Logistics operates 200,000 square feet of public and contract warehouse space across four locations in Hampton Roads, allowing them to effectively manage a variety of logistics needs.

What is the difference between utilization and capacity in logistics?

Utilization measures how effectively resources are employed, expressed as a percentage of the total potential utilized. Capacity refers to the maximum amount of resources available. For example, if a warehouse has a capacity of 100,000 square feet but only utilizes 80,000 square feet, its utilization rate is 80%.

Why is understanding utilization vs capacity important for logistics coordinators?

Understanding utilization vs capacity is crucial for coordinators as it directly impacts operational efficiency and resource allocation. High resource utilization indicates effective use, while low utilization may suggest inefficiencies or excess capacity.

How does effective management of warehouse capacity benefit a transportation firm?

Effective management of warehouse capacity allows a transportation firm like Crossfire Logistics to respond swiftly to fluctuations in demand, ensuring timely deliveries and cost reductions, which boosts productivity and aligns with industry standards emphasizing operational efficiency and customer satisfaction.